Composite type base plate transportation box

A substrate handling and transport box technology, applied in the field of transport boxes, can solve the problems of difficult manufacturing, difficult molding, large accumulation and inventory space, etc., to achieve the effect of reducing manufacturing costs, reducing occupied space, and solving difficult manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

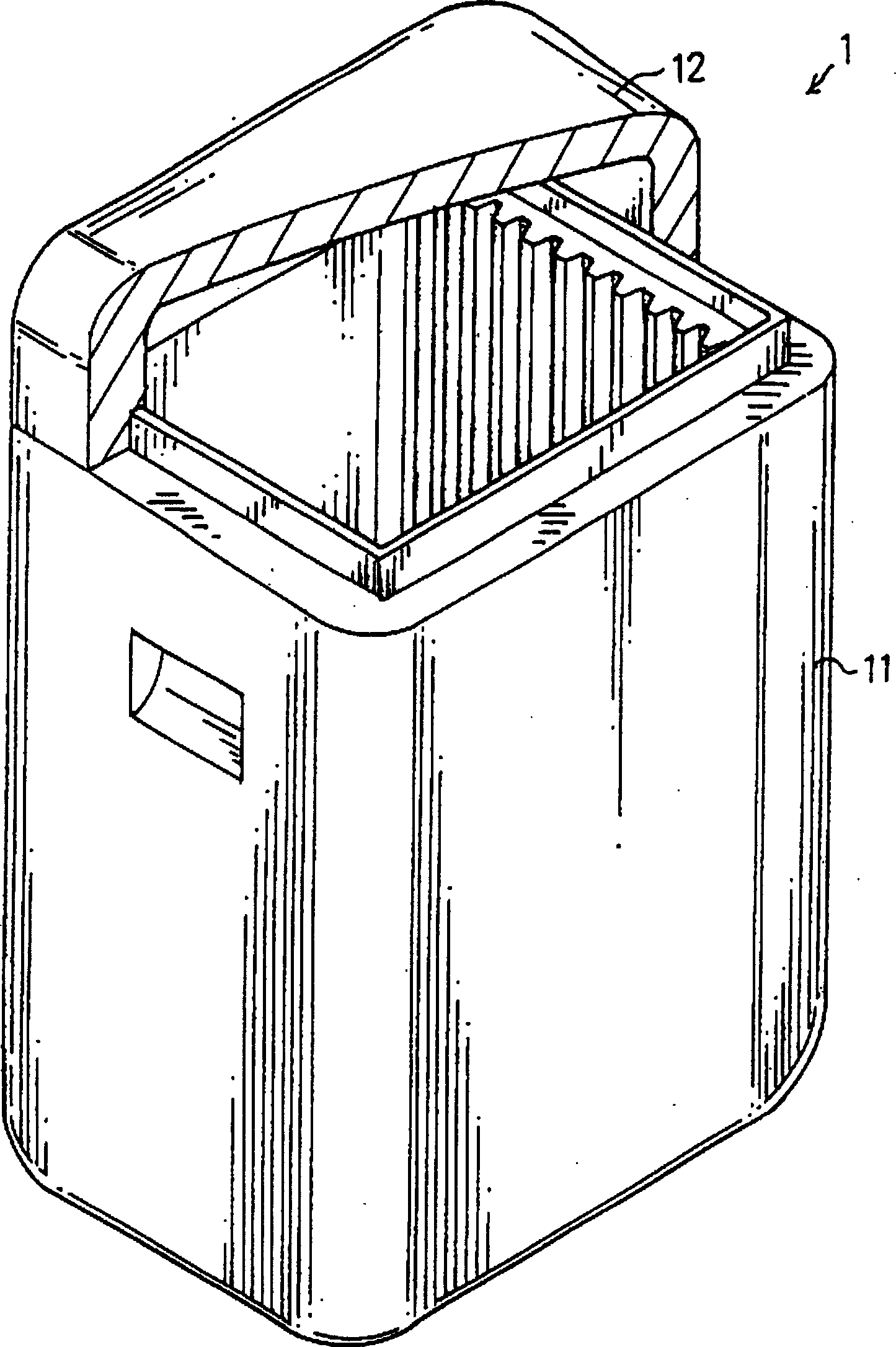

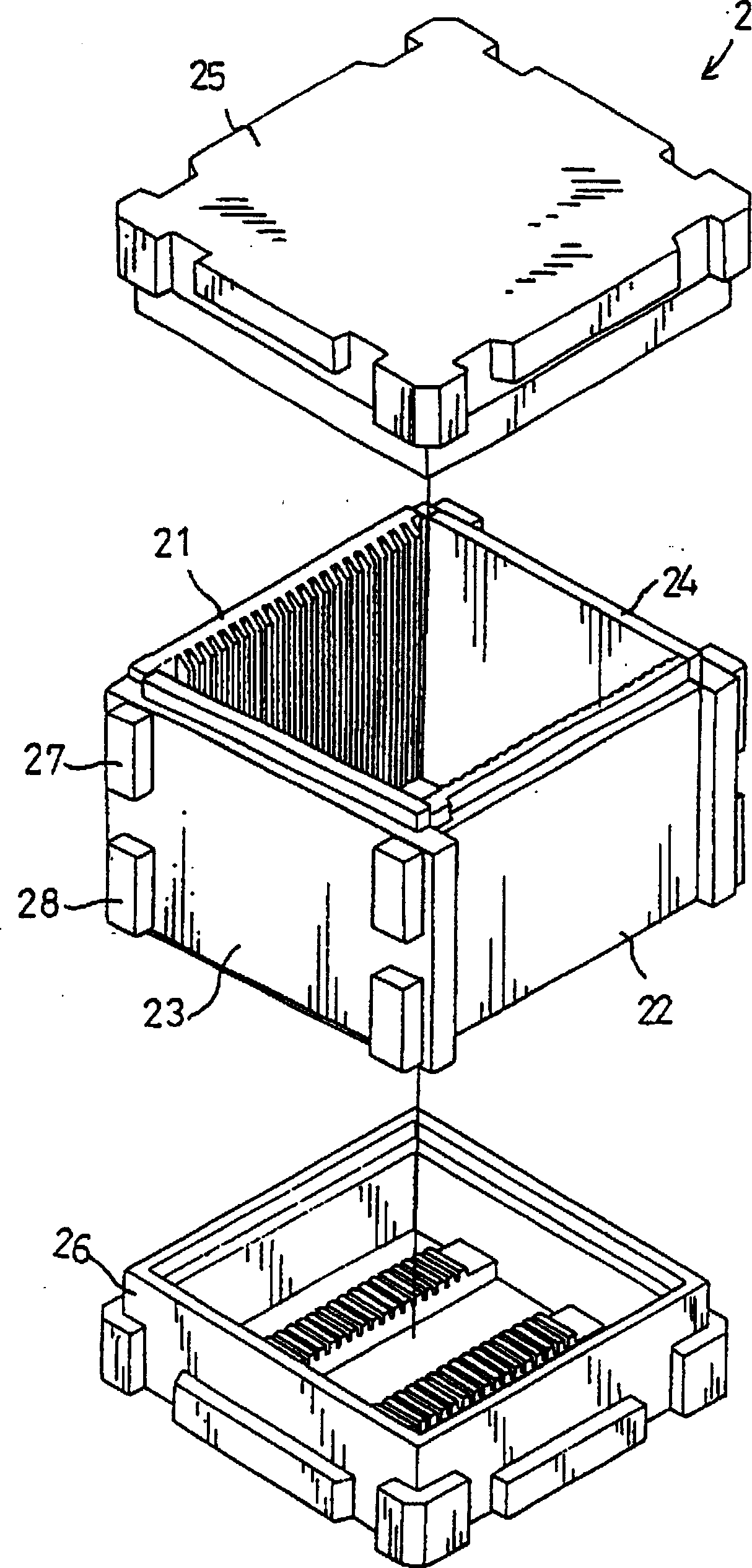

[0037] refer to figure 2 The combined substrate transport box 2 of the present invention includes two opposite first side panels 21 , 22 , two opposite second side panels 23 , 24 and two opposite cover panels 25 , 26 . The combined substrate handling box 2 is composed of two first side panels 21, 22 and two second side panels 23, 24 to form the side wall of the handling box 2, and then the top and bottom of the side wall of the handling box 2 are respectively Cover the two cover plates 25, 26 to complete the assembly. The two first side panels 21 , 22 , the two second side panels 23 , 24 and the two cover panels 25 , 26 respectively have the same structure.

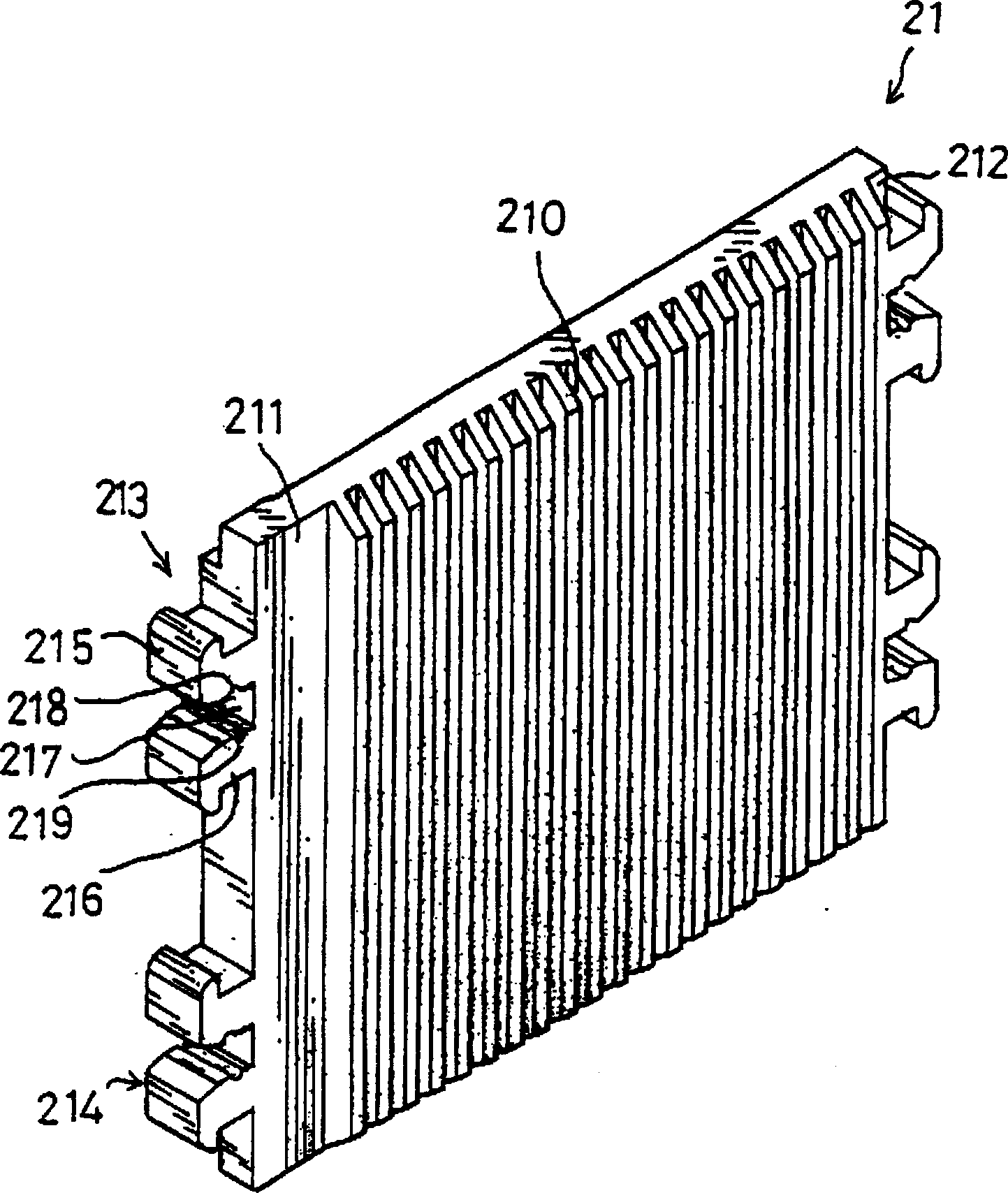

[0038] refer to image 3 , taking one of the first side plates 21 as an example, it has two symmetrical upright sides 211 , 212 . Taking the upright side 211 as an example, the upright side 211 has two extension protrusion sets 213 , 214 respectively extending outward from the upright side 211 , and the two extension ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com