Placode processor and liquid feeder

A technology for a substrate processing device and a liquid feeding device, which is applied in door/window protection devices, devices for coating liquid on surfaces, and liquid variable volume machines, etc. Problems such as particle mixing, etc., to achieve the effect of easy cleaning and other maintenance, easy drainage, and reduced attractiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 2 Embodiment approach

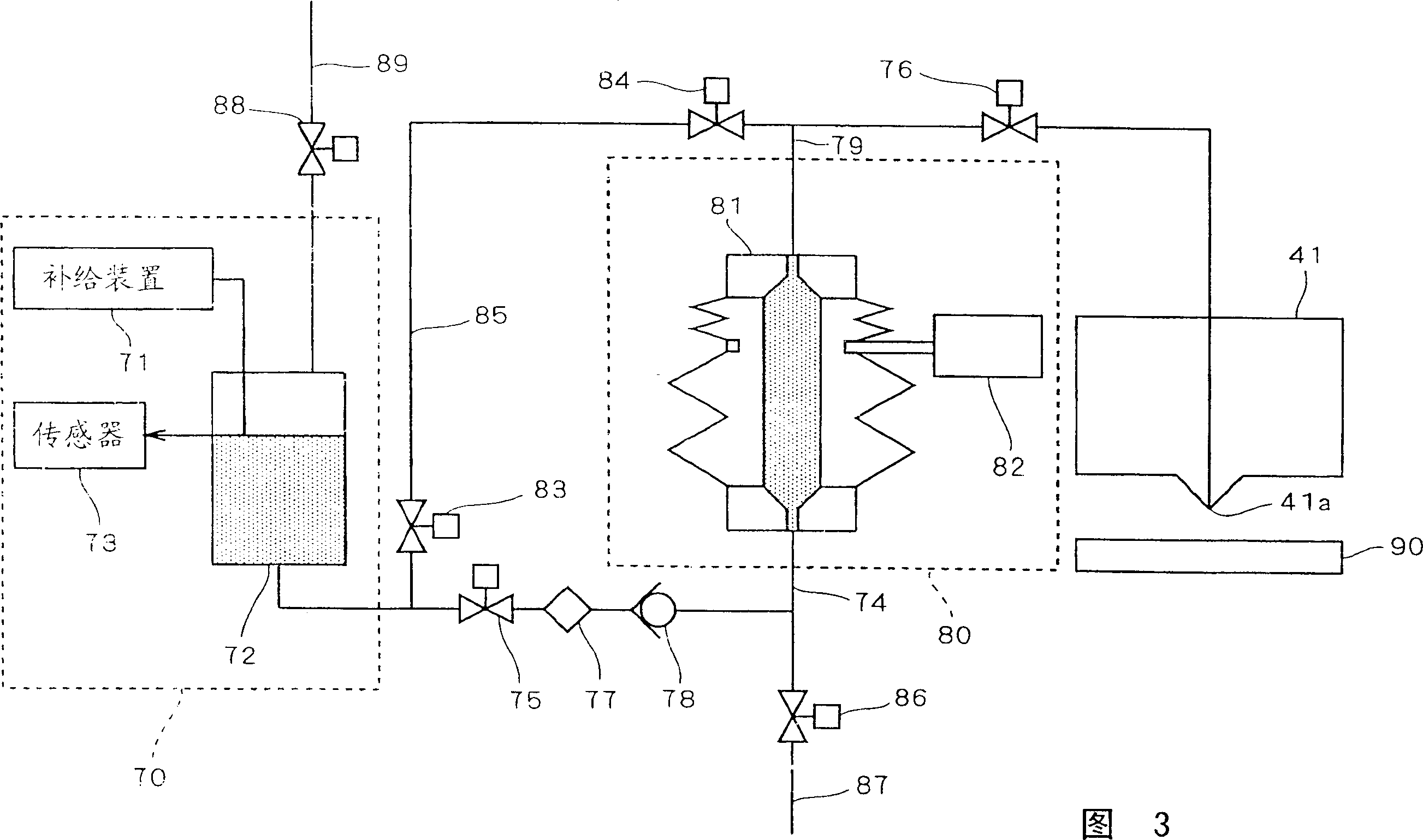

[0179] In the substrate processing apparatus 1 according to the first embodiment, the resist liquid is sent to the slit nozzle 41 by one resist liquid pump 81 . Here, when the volume of the substrate 90 to be processed is large and it is necessary to increase the discharge amount per one pass of the coating process, conventionally, the resist solution pump 81 has been replaced with a large pump with a large discharge amount. . However, it is difficult to manufacture such a large pump with high precision, and as a result, there is a problem that the coating accuracy is lowered. In the present invention, like the substrate processing apparatus 1 shown in the first embodiment, the pump for feeding the resist liquid is not limited to one, but may be plural.

[0180] Figure 6 It is a diagram showing the connection relationship between the liquid feeding mechanism 80 a and the slit nozzle 51 of the substrate processing apparatus 1 according to the second embodiment configured bas...

no. 3 Embodiment approach

[0206] The substrate processing apparatus 1 of the second embodiment has two drive mechanisms 82a, 82b for driving the two protection pumps 81a, 81b, and the respective drive mechanisms 82a, 82b independently drive the respective resist liquid pumps 81a, 81b. Therefore, the control system 6 controls the drive units 82a and 82b in synchronization so that the discharge flow rates of the resist liquid pump 81a and the resist liquid pump 81b are equal. However, the method of synchronously driving the two resist liquid pumps 81a and 81b is not limited to the case of being controlled by the control system 6, and may be performed mechanically, for example.

[0207] Figure 8 It is a schematic diagram of the connection relationship between the liquid feeding mechanism 80b and the slit nozzle 41 of the substrate processing apparatus 1 according to the third embodiment configured based on this principle. In addition, in the substrate processing apparatus 1 of this embodiment, the struc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com