Surface matrix type pit machining method and apparatus

A processing device and matrix technology, applied in metal processing equipment, milling devices that can be installed on machine tools, manufacturing tools, etc., can solve problems such as difficult processing, low efficiency, and long processing time of parts, and achieve uniform distribution and regular arrangement good performance and improve the overall efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

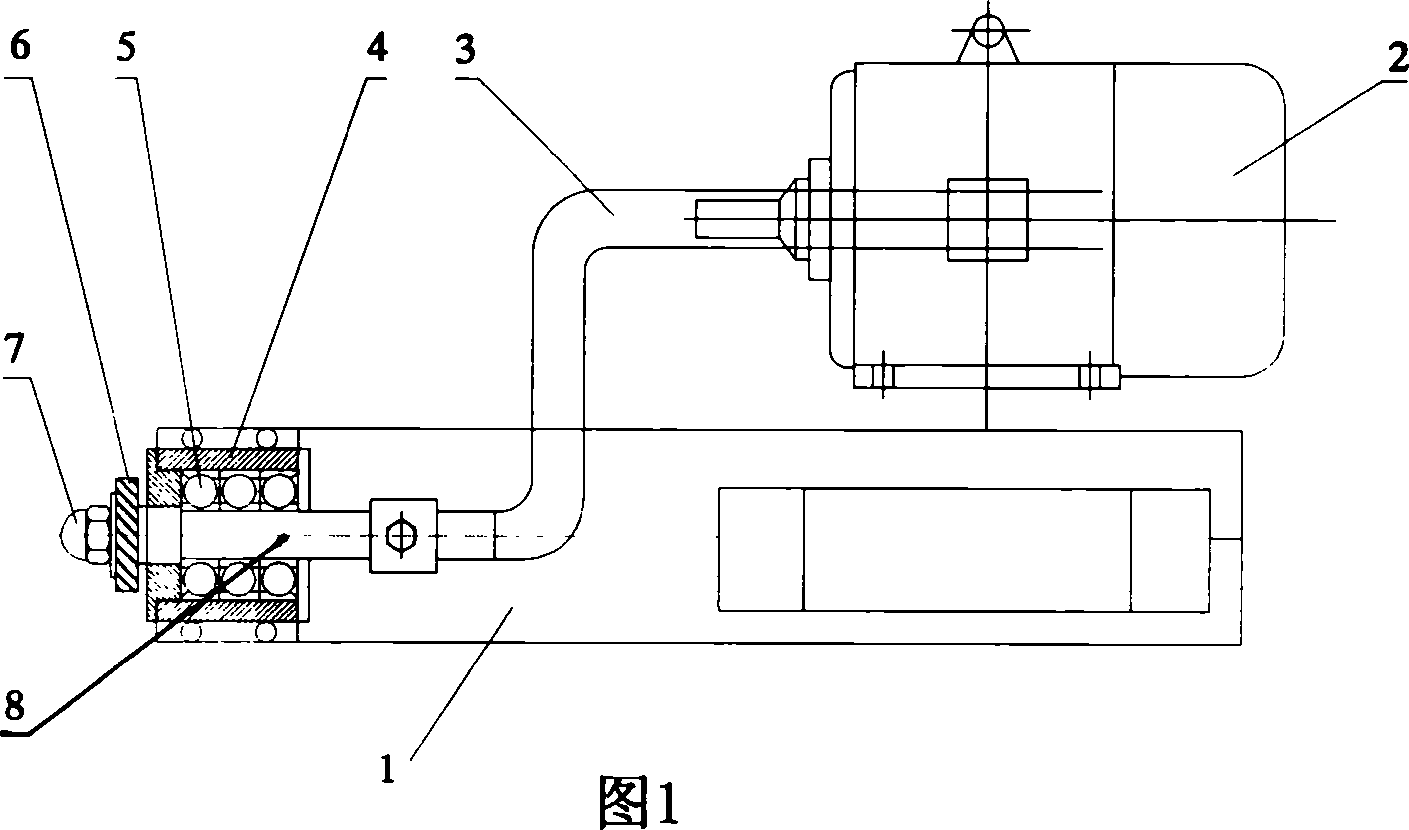

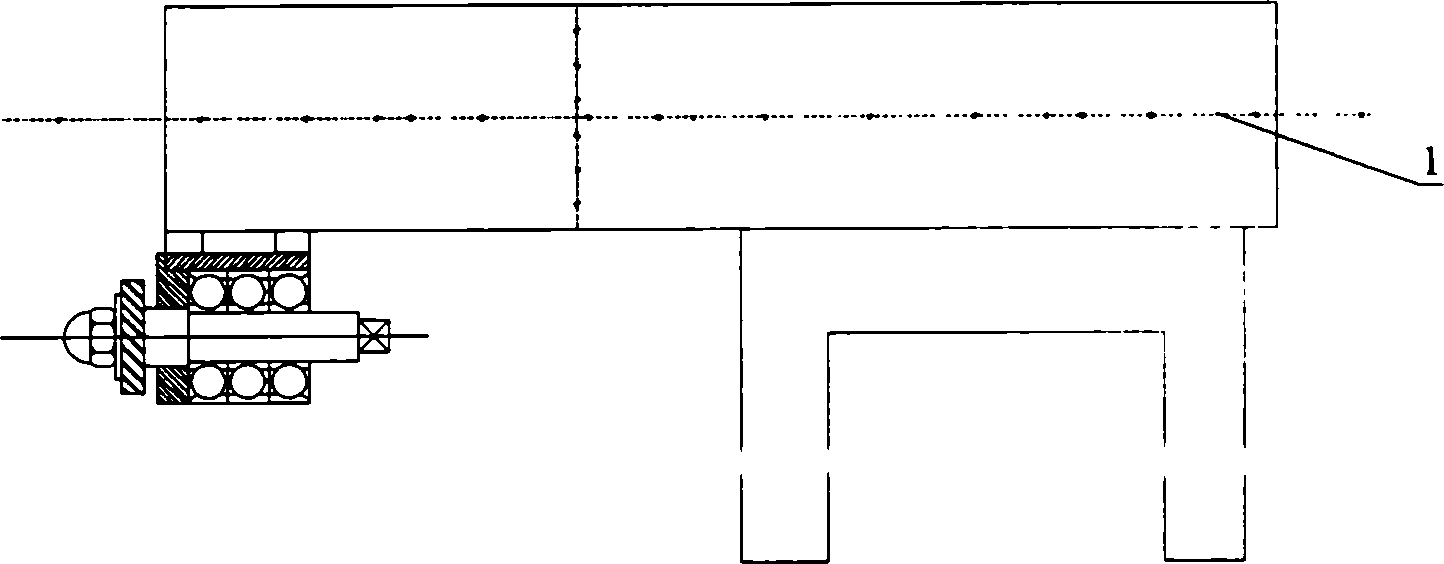

[0012] figure 1, figure 2 and image 3 As shown, the surface matrix micropit processing device of the present invention includes: a tool holder 1 , a motor 2 , and a transmission shaft 3 . There is a rotary shaft 8 on the cutter bar, and the rotary shaft belt bearing 5 is installed in the bearing seat 4, and the bearing seat is fixed on the cutter bar by bolts; Milling cutter 6 is installed before the rotating shaft, and is fastened by cap nut 7.

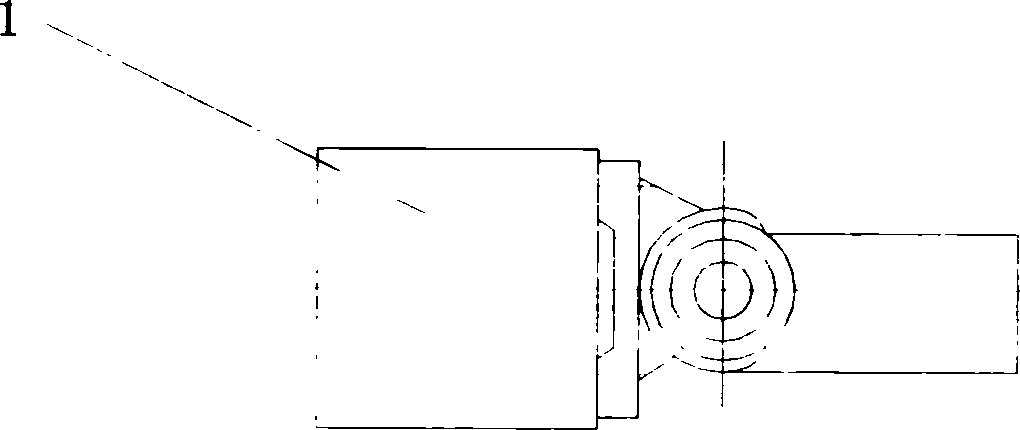

[0013] Figure 4 As shown, the milling cutter of the surface matrix micropit processing device has a diameter of 16 to 40 mm, and the number of teeth: 4, 6, 8, 12, 16, etc.

[0014] The following is the process of processing the cylinder liner using the surface matrix micro-pit processing device:

[0015] The cylinder liner is installed on the main shaft of the lathe, the tool bar 1 is installed on the small tool holder of the lathe slide box, the motor 2 is installed at the tailstock of the lathe, and the motion is transmitted ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com