Fresh green zanthoxylum oil production process

A technology of fresh green Sichuan pepper oil and production process is applied in the field of production technology of fresh green Sichuan pepper oil to achieve the effects of reducing loss and controlling the increase of water content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

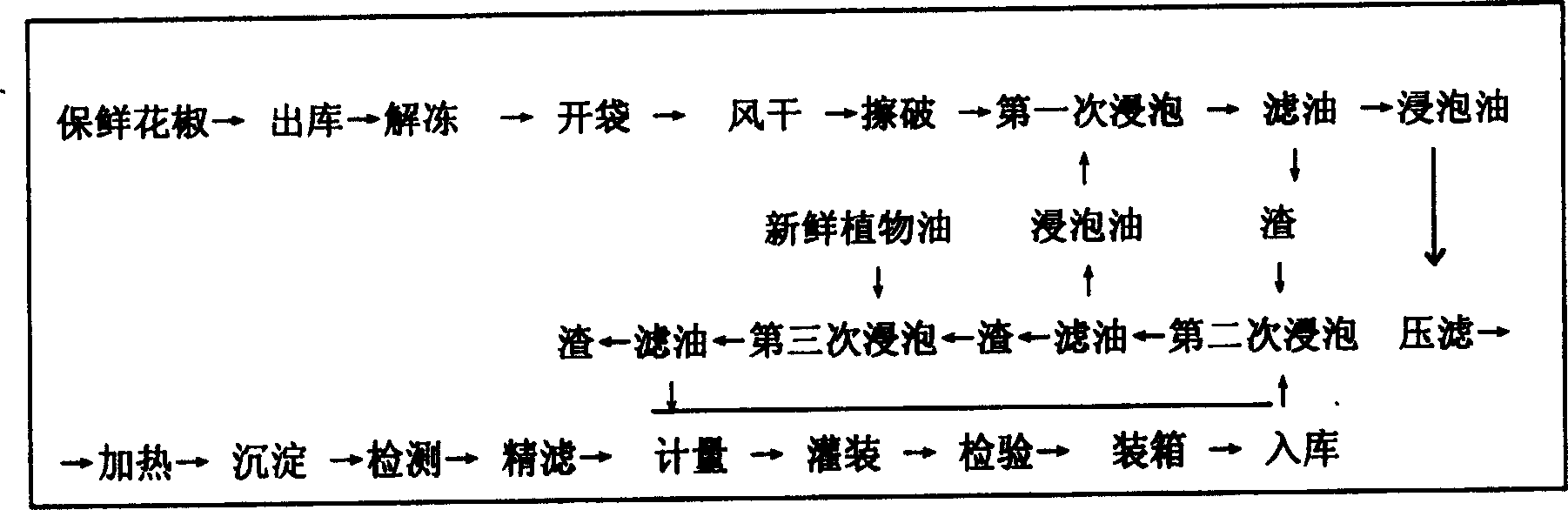

[0011] The present invention will be further explained below with reference to a non-limiting process flow given in conjunction with the accompanying drawings. The technological process in the embodiment is as follows.

[0012] 1. Thaw

[0013] When the preserved pepper is used as the raw material, the preserved pepper is first thawed naturally at room temperature (10-20° C.) before soaking, and the thawing time is based on the fact that there is no ice crystal in the bagged pepper and the pepper is loose.

[0014] 2. Scratch

[0015] First of all, after the open water on the surface of the peppercorns is air-dried after opening the bag, the peppercorns are rubbed in a special scraping machine using the friction between the ribs on the roller, the cavity wall, and the peppercorns to scrape the oil cells on the surface of the peppercorns and control the axis The rotating belt is 100-150rpm, and the time is 3-8min.

[0016] 3. Countercurrent soaking

[0017] Use three counte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com