Convex/concave pattern-forming stamp, convex/concave pattern-forming method and magnetic recording medium

A technology of concave-convex pattern and embossing mold, which is applied in the manufacture of record carriers, the support of paint carriers, and the device for coating liquid on the surface, etc., can solve the problems of uneven depth of concave parts, deformation and peeling of track formation areas, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] Hereinafter, the best embodiments of the embossed-and-convex pattern-forming imprint mold, the method for forming the concave-convex pattern, and the magnetic recording medium according to the present invention will be described with reference to the accompanying drawings.

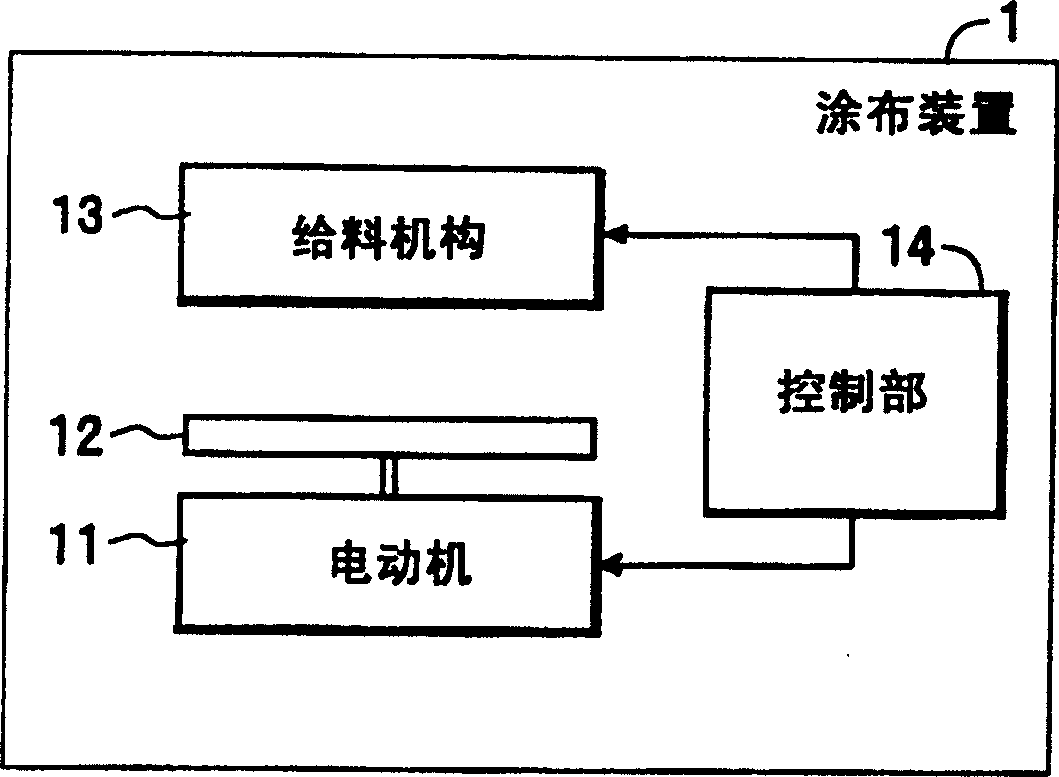

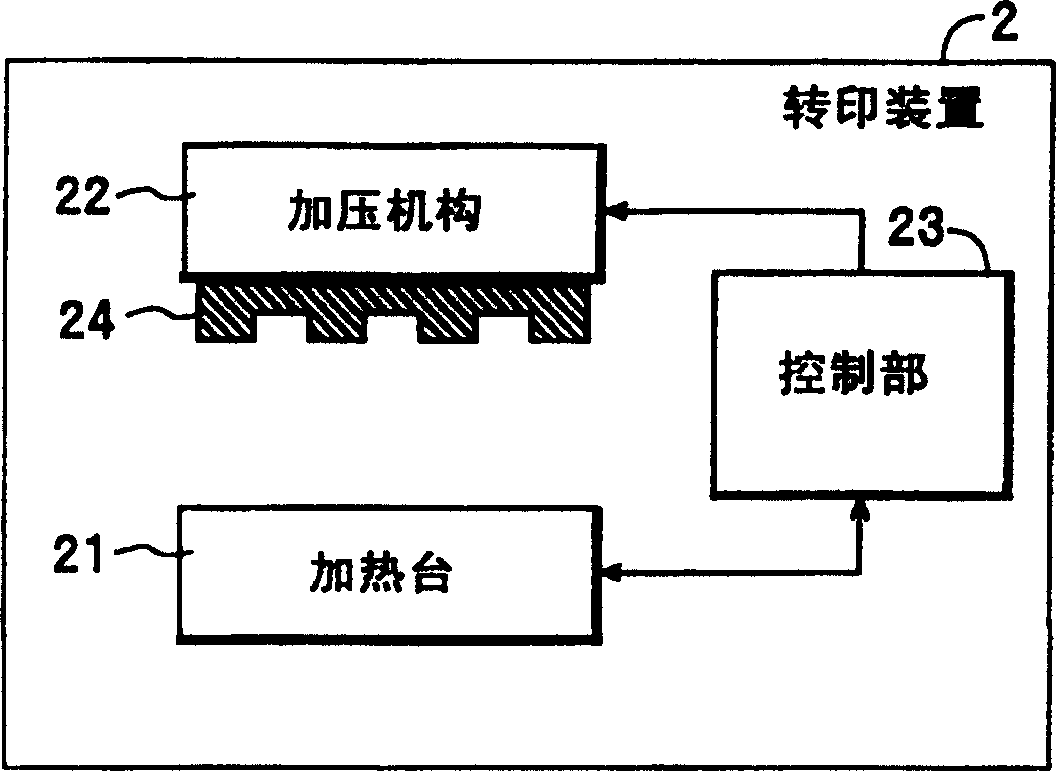

[0039] First, the configuration of the coating device 1 and the transfer device 2 will be described with reference to the drawings.

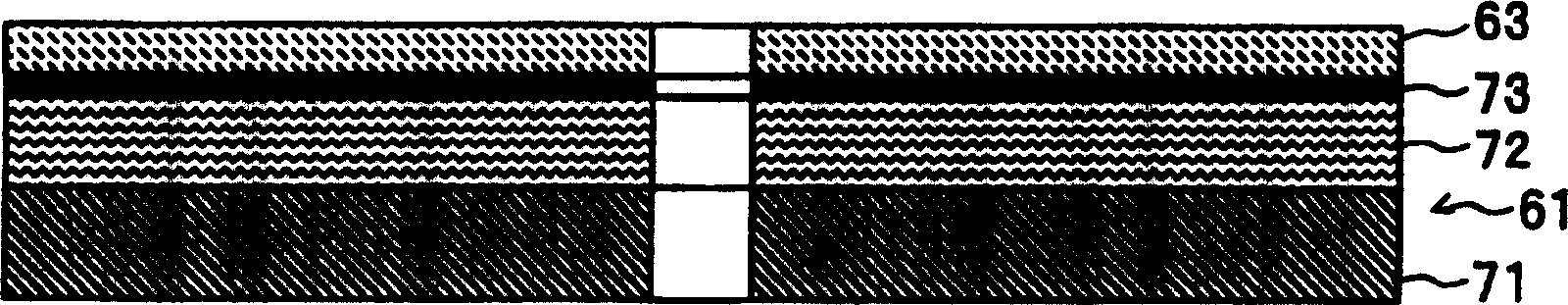

[0040] figure 1 The coating device 1 shown is that the resin material is coated on the disk-shaped base material 61 according to the concave-convex pattern forming method related to the present invention (refer to figure 2 ) to form a resin layer 63 on the surface (refer to figure 2 ) device is composed of a motor 11, a turntable 12, a feeding mechanism 13 and a control unit 14. The motor 11 rotates the turntable 12 according to a control signal of the control unit 14 . The structure of the turntable 12 is made to carry the disc-shaped base material 61 and is ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com