Automatic control method for hanging scum plug casting device

The technology of a throwing device and a slag blocking plug, which is applied in the field of auxiliary equipment, can solve the problems of low slag blocking success rate and high slag blocking success rate, and achieve the effects of accurate throwing, reducing labor intensity and improving the success rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

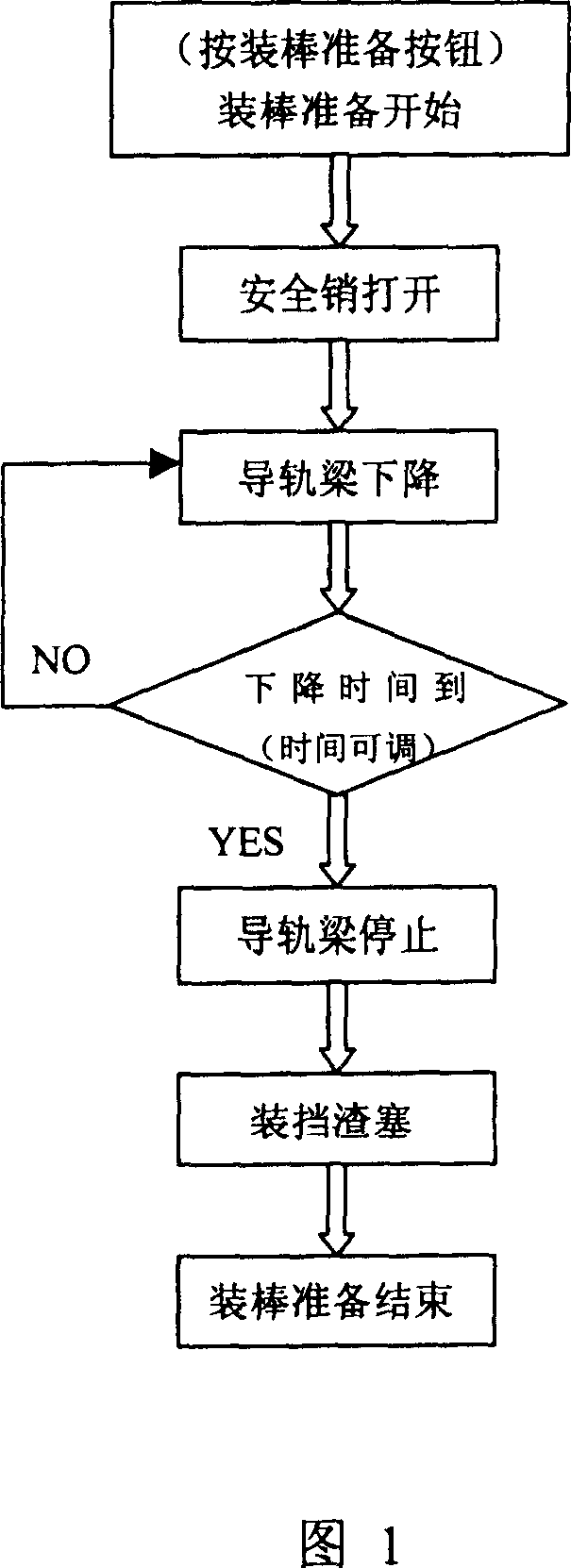

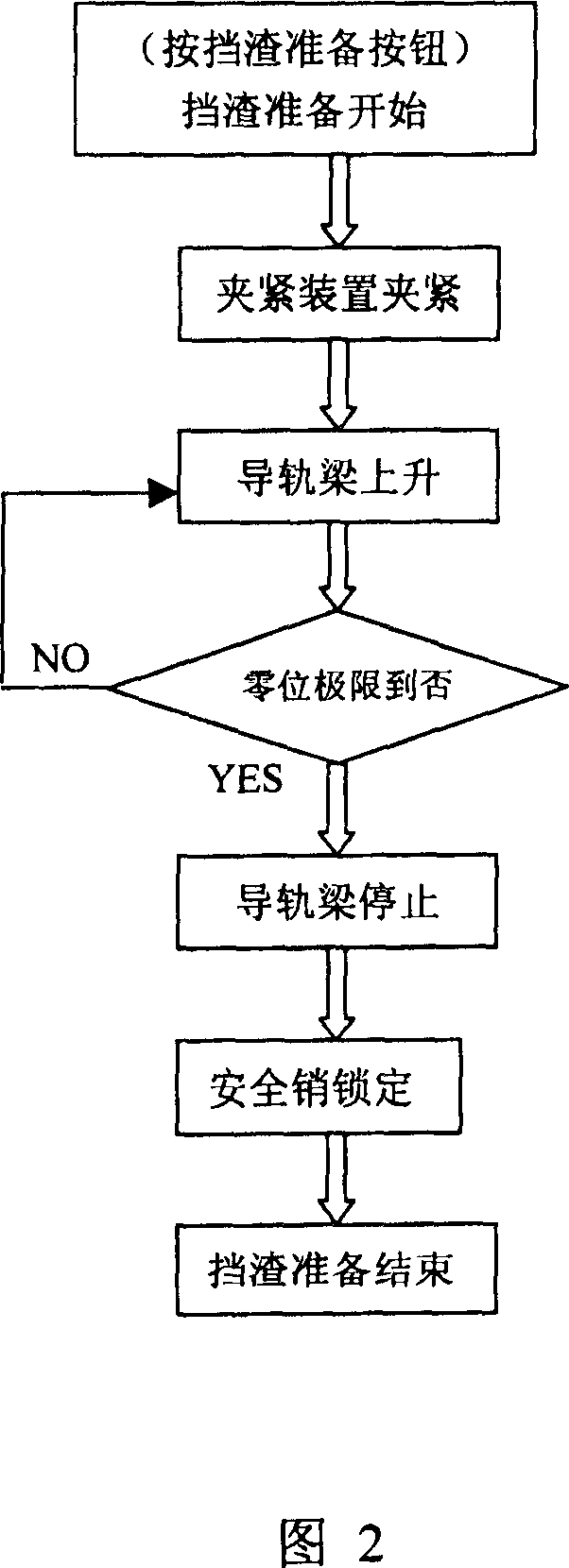

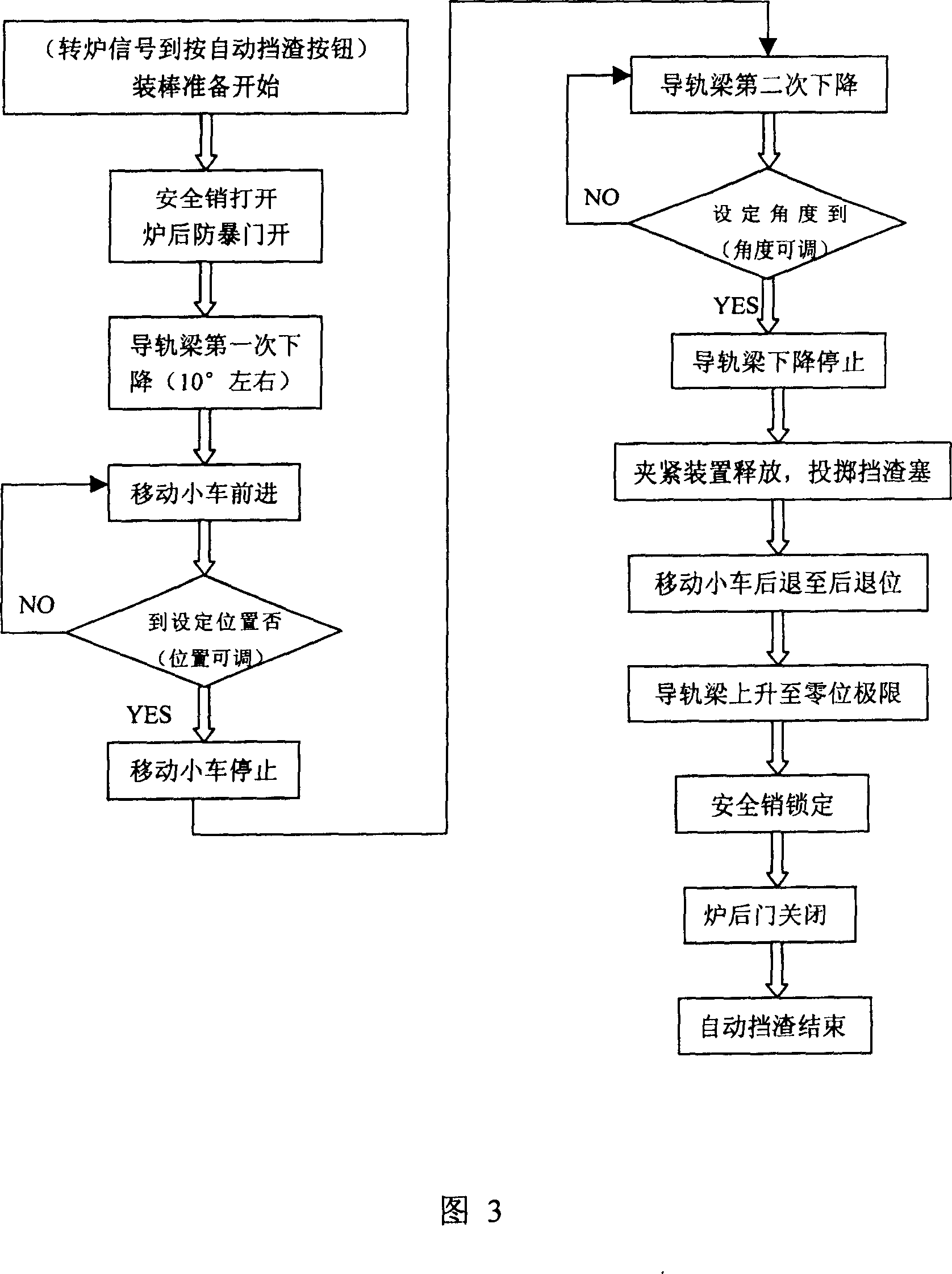

[0019] Referring to Fig. 1, Fig. 2 and Fig. 3, an automatic control method of a hanging dross stopper throwing device includes a plugging preparation stage, a slag stopper preparation stage and an automatic slag stopper stage. Referring to Figure 1, the plugging preparation stage includes opening the safety pin, lowering the guide rail beam, judging when the guide rail beam descends, and stopping the guide rail beam when the time is up, installing a slag stopper under the guide rail beam, and the preparation for plugging is completed. Referring to Figure 2, the slag blocking preparation stage includes the clamping device clamping the slag blocking plug, the guide rail beam rising, the zero position limit judgment, the guide rail beam stops when it reaches the zero limit, the safety pin is locked, and the slag blocking preparation is completed. Referring to Fig. 3, the automatic slag-retaining stage includes: opening of the safety pin, opening of the explosion-proof door behind ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com