Centrifugal governor for transverse diesel motor

A technology of centrifugal governor and diesel engine, applied in governor, engine control, machine/engine, etc., can solve the problem of not being able to increase the speed increase, not being able to minimize the rate of change of the rated speed of the high-load gear, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

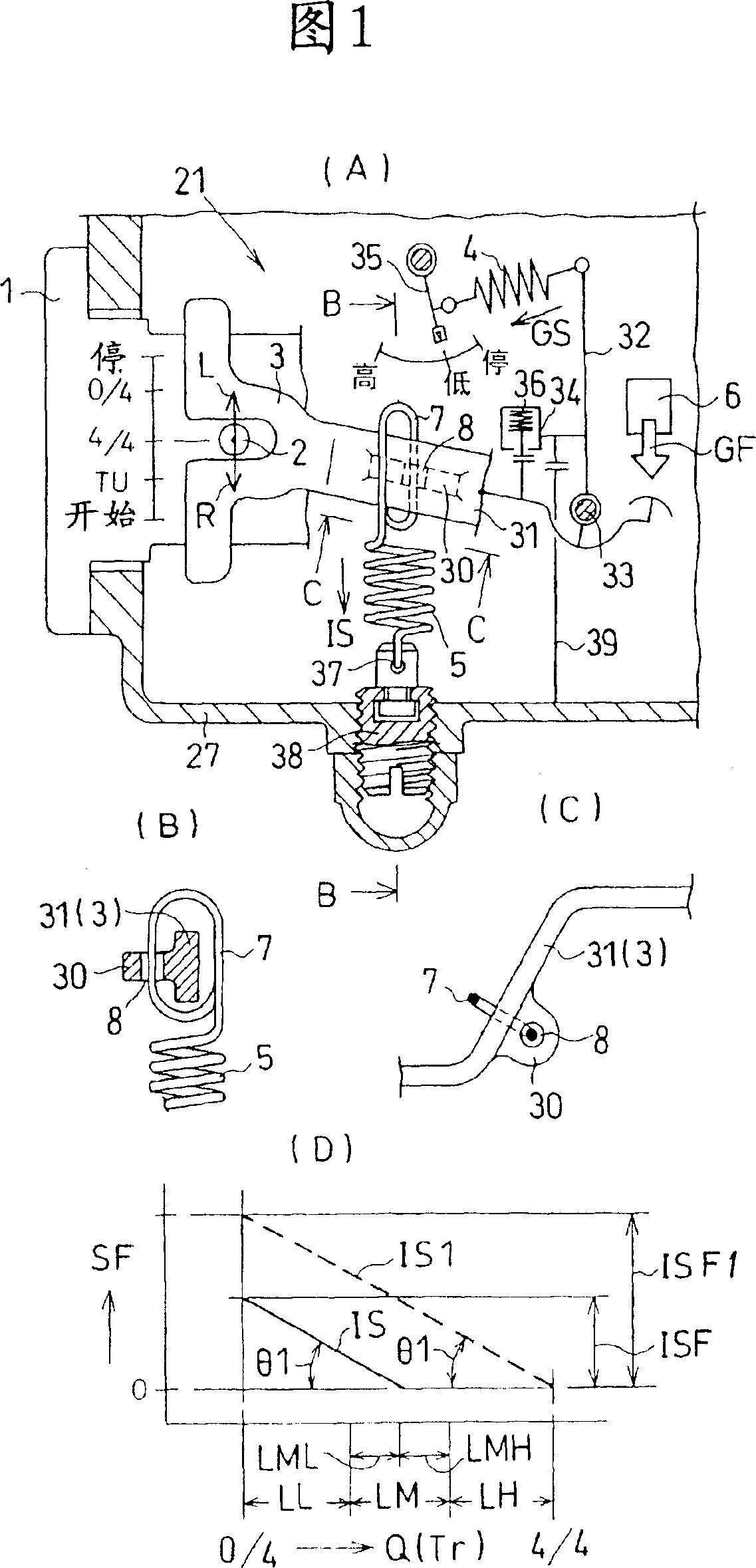

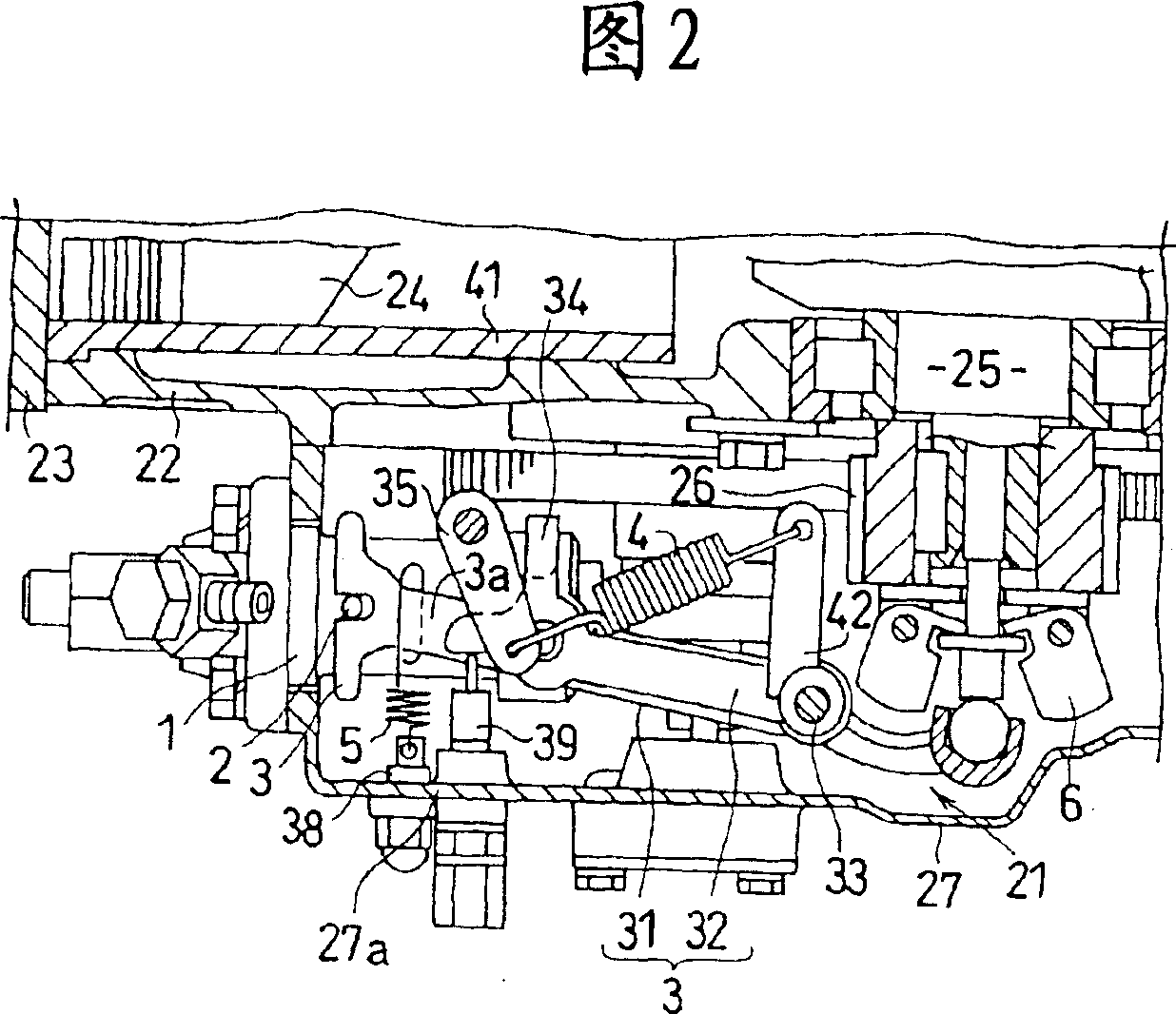

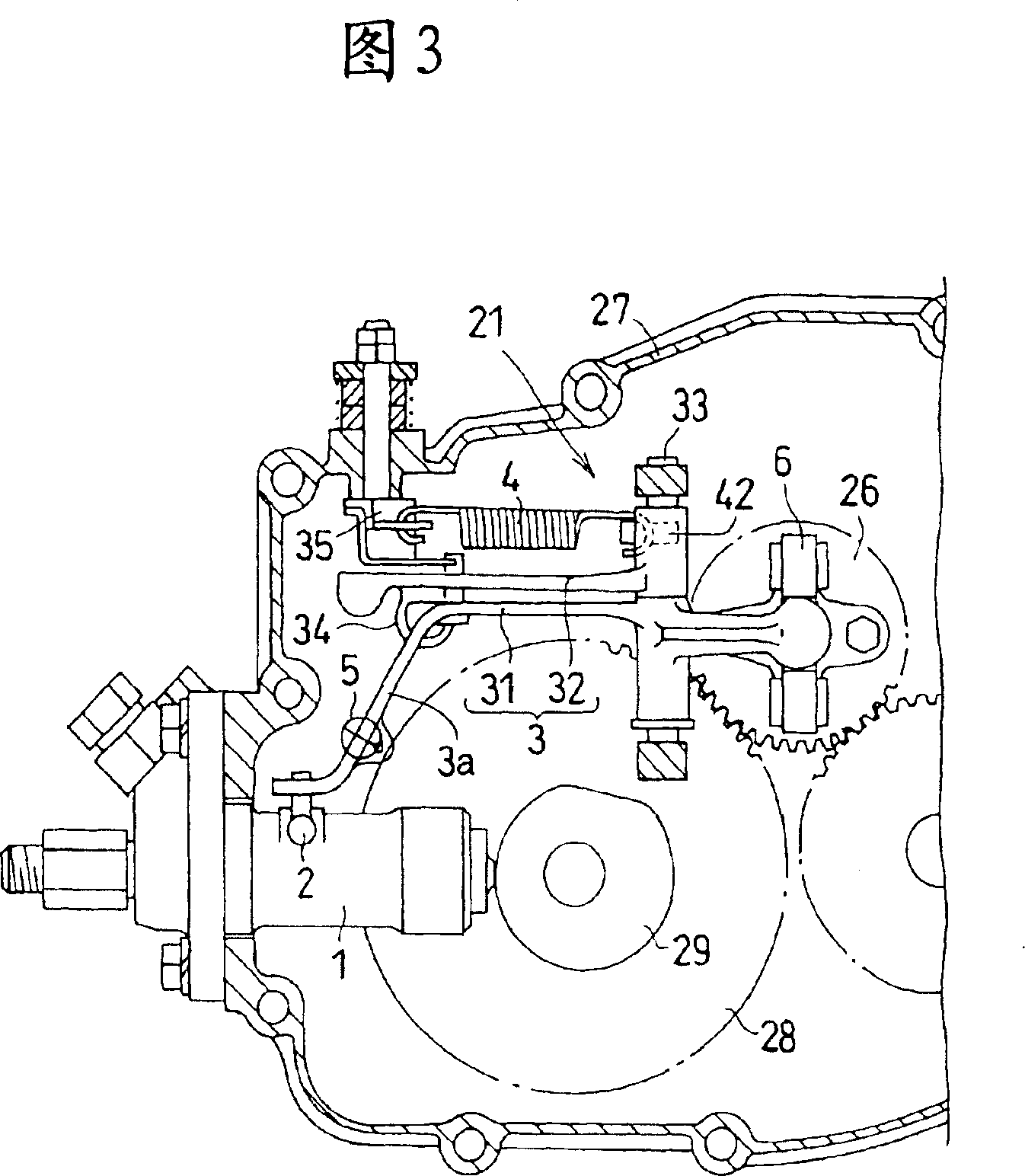

[0029] Referring to Figures 1 to 5, the present invention will be specifically described by way of example.

[0030] As described above, the centrifugal speed governor of the present invention is basically the same in structure as the conventional centrifugal speed governor. As stated at the outset, the centrifugal governor according to the invention is used in a water-cooled transverse diesel engine.

[0031] Specifically, as shown in FIGS. 2 and 3 , the centrifugal speed governor 21 is provided with a cylinder block 22 in which a cylinder 41 is placed horizontally and a crankshaft 25 arranged vertically. A gearbox 27 is arranged in front of the cylinder block 22 , a fuel pump 1 is arranged near the cylinder 41 inside it, and a governor counterweight 6 is arranged near the crankshaft 25 . Between the counterweight 6 and the fuel pump 1, a governor rod 3, preferably T-shaped, is arranged. The governor lever comprises a counterweight side lever 31 , a spring side lever 32 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com