Connector

A connector and pipe connection technology, applied in the direction of couplings, mechanical equipment, etc., can solve the problems of high cost, troublesome forming, easy to fall off, etc., and achieve the effect of improving rigidity, superior assembly operability, and preventing friction loss or deformation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In order to further clarify the structure and operation of the present invention described above, preferred embodiments of the present invention will be described below.

[0037] (1) Outline of the structure of the connector 10

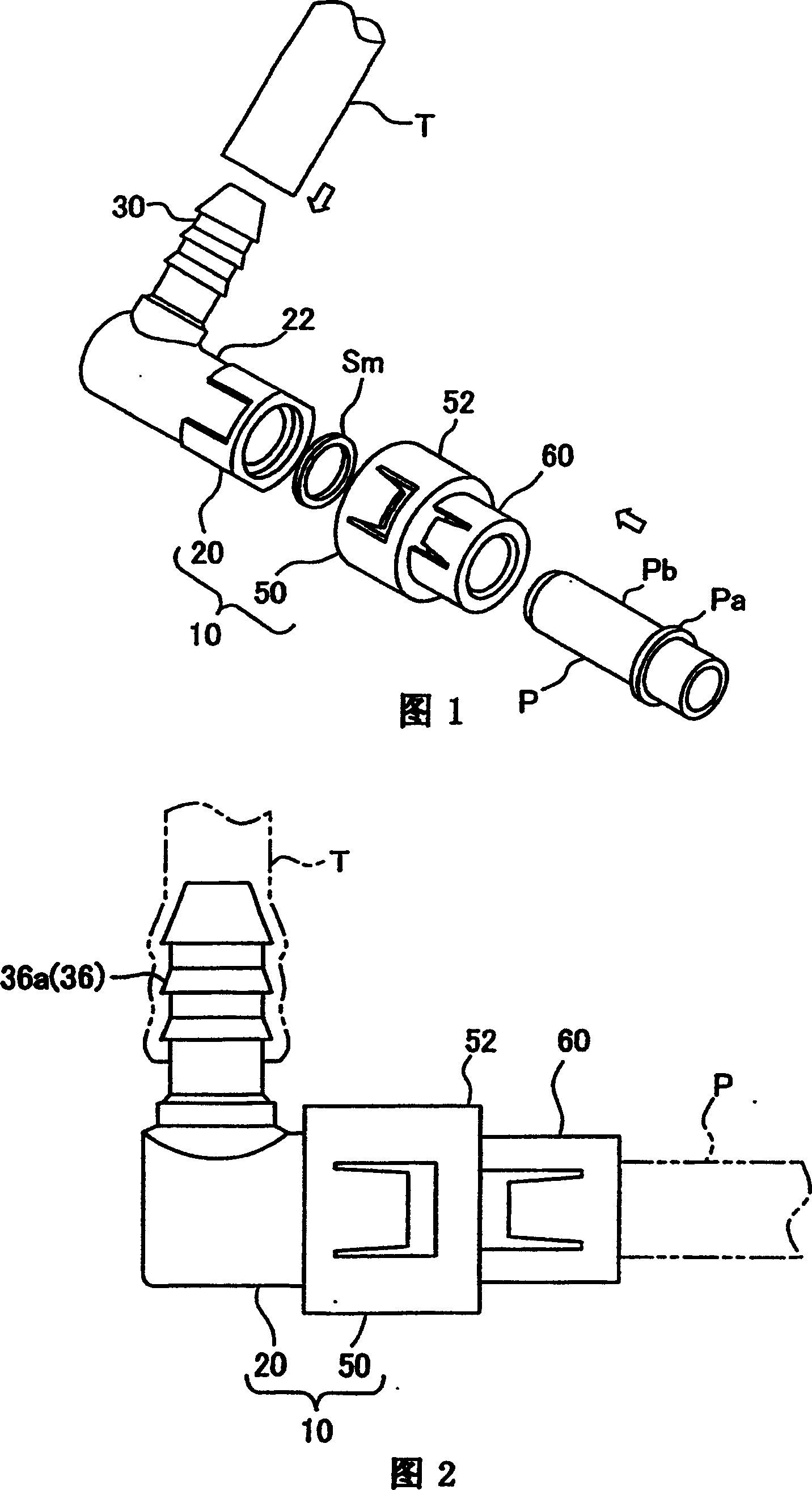

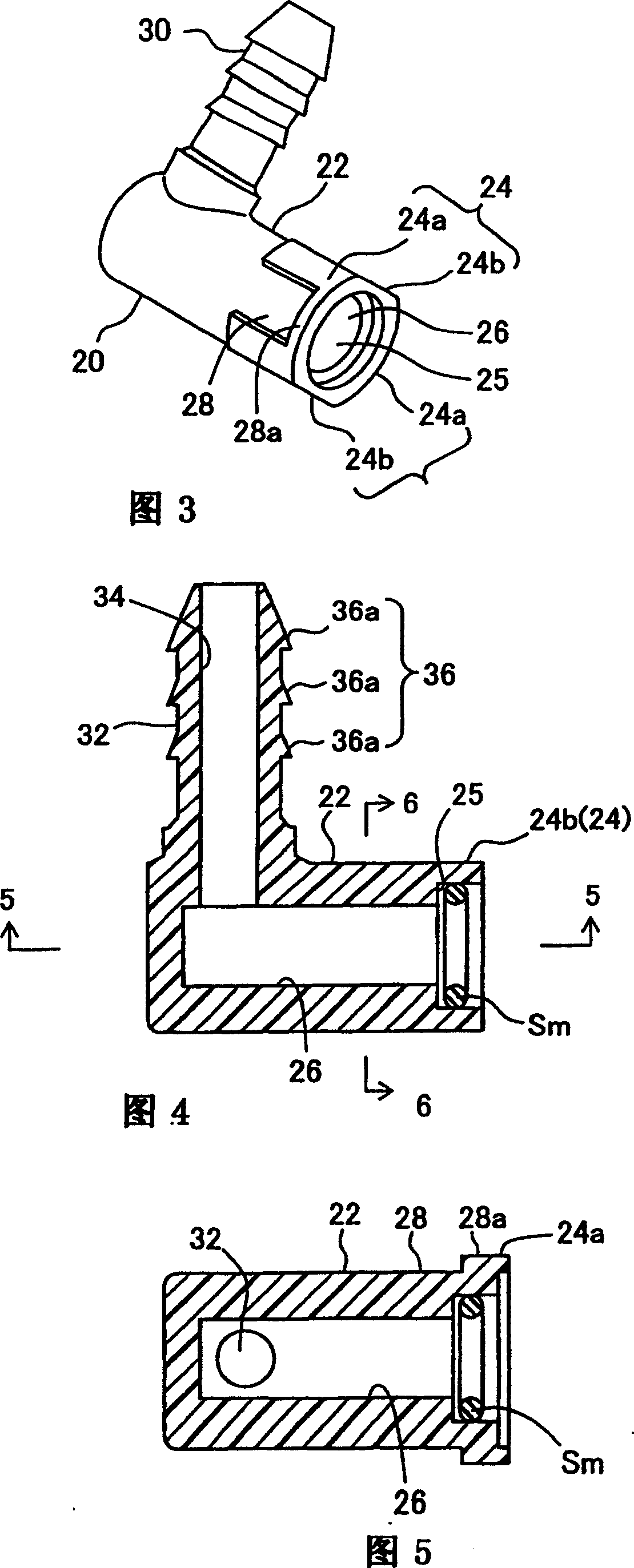

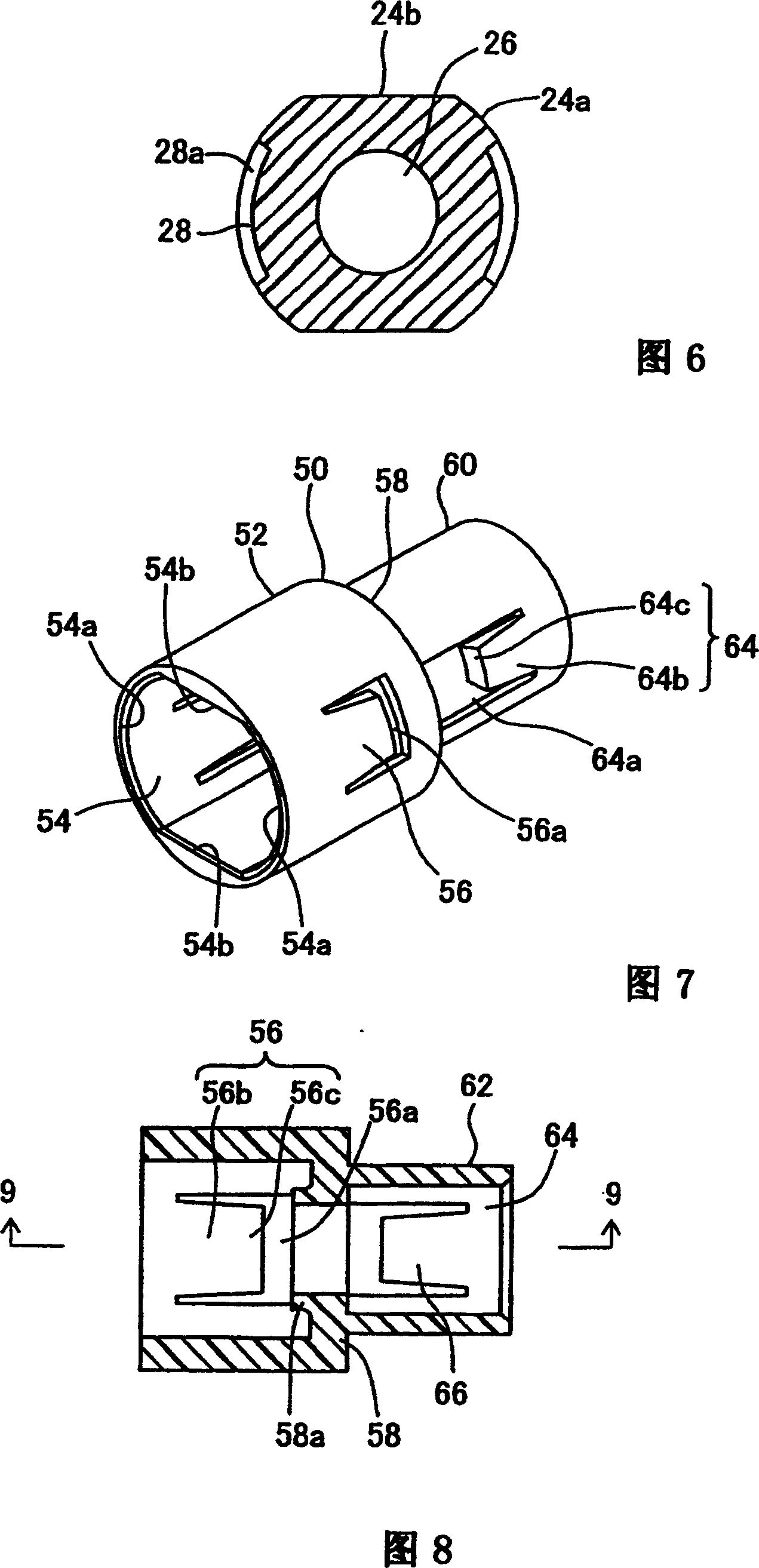

[0038] The connector according to the present invention can be suitably arranged, for example, on a fuel passage of a fuel tank of an automobile. 1 is a perspective view illustrating a connection structure before connecting a pipe P and a hose T to a connector 10 according to an embodiment of the present invention, and FIG. 2 is a side view of the connector 10 . In FIGS. 1 and 2 , the connector 10 includes a connector body 20 , a retainer 50 assembled to the connector body 20 , and a seal member Sm inserted into the connector body 20 to seal the pipe P. As shown in FIG. The pipe P has a flange Pa protruding from its outer peripheral portion, and the outer peripheral surface on the front end side of the flange Pa serves as a sealing surface Pb,...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap