Shock-absorbing mechanism of motor bearing

A bearing and motor technology, applied in the field of anti-vibration mechanism of shaking or vibration, can solve the problems of increasing vibration and abnormal sound, shaking of the shaft 14, generating vibration, etc., to achieve the effect of increasing the life of the fan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

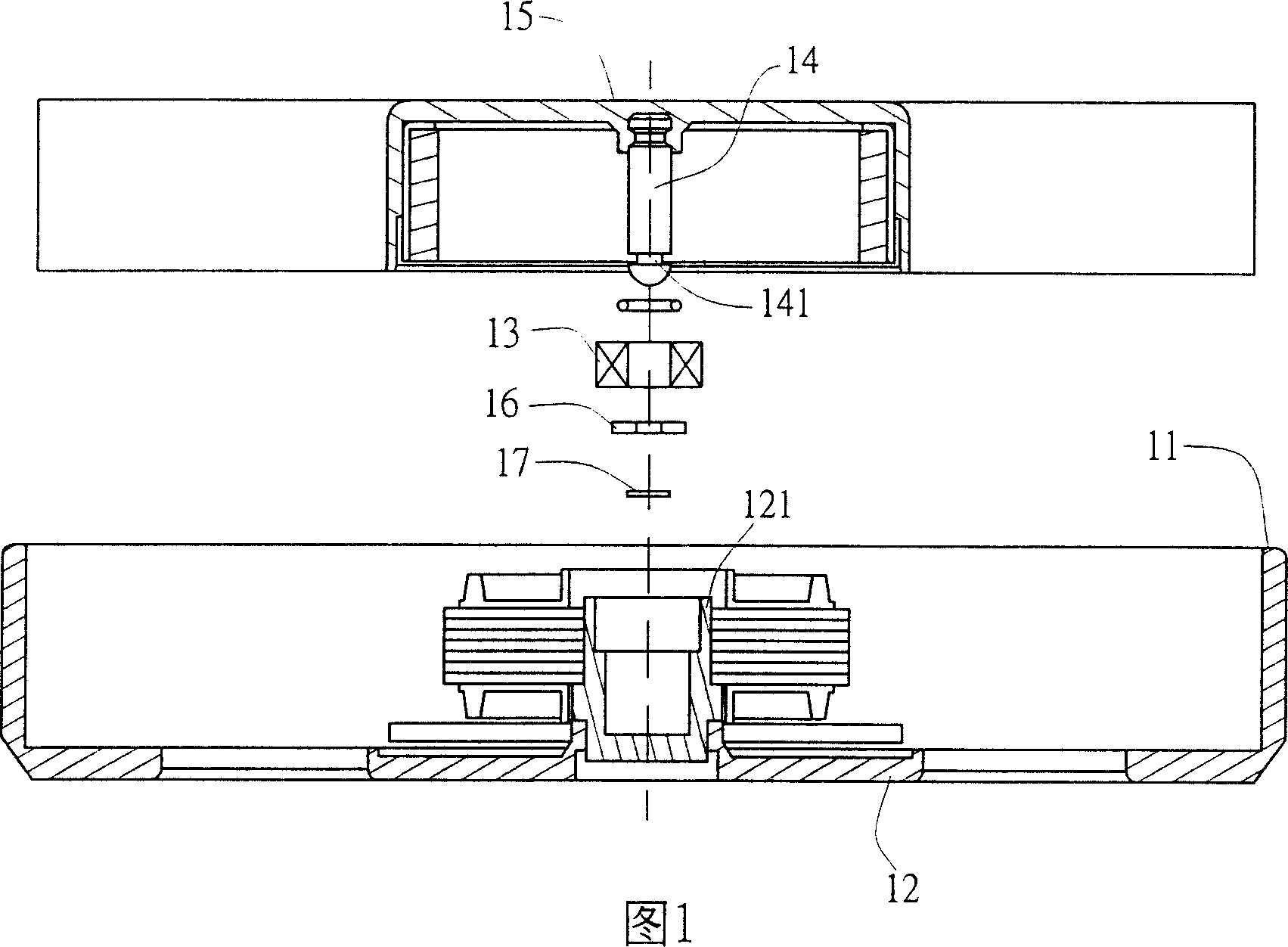

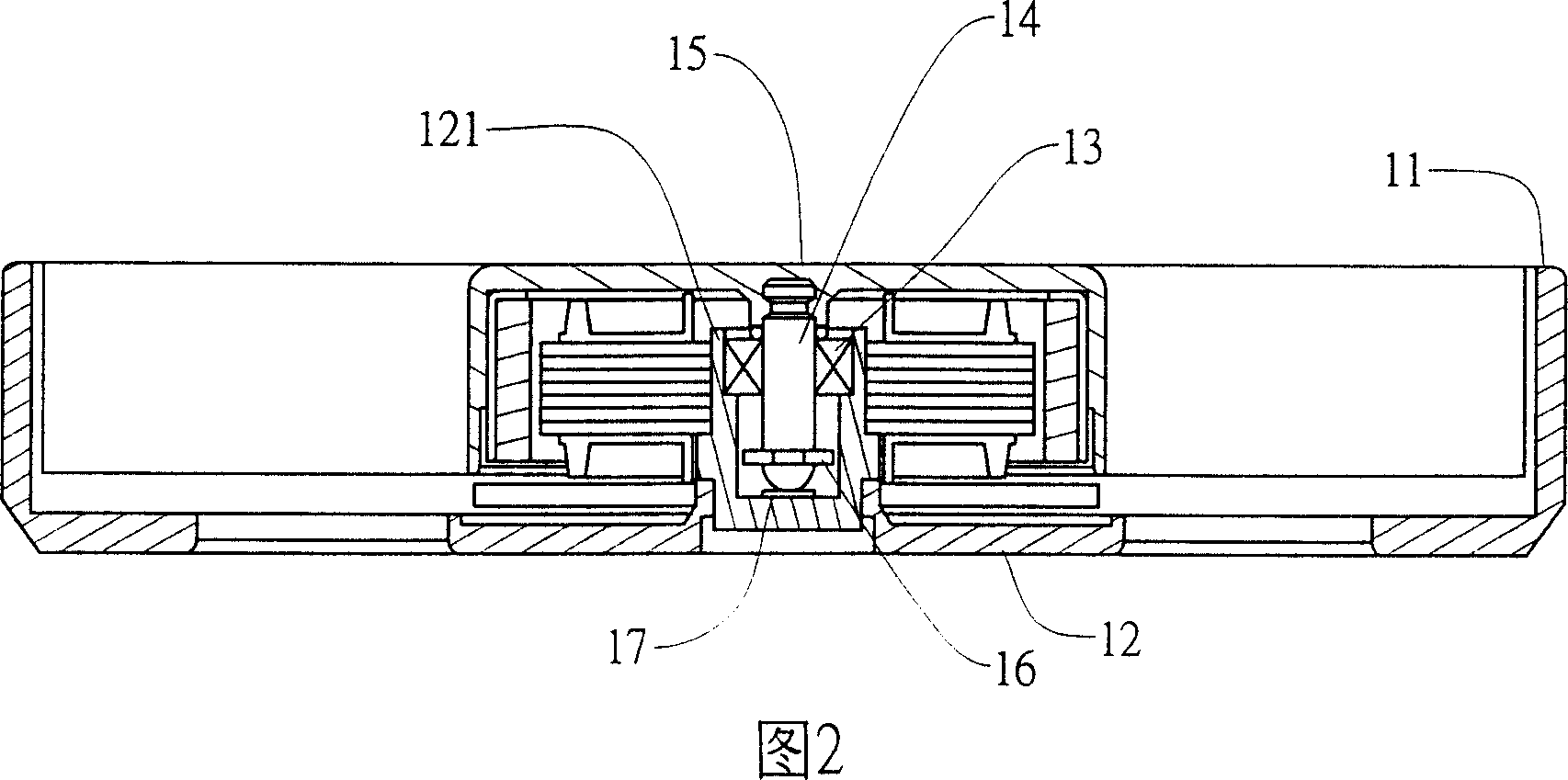

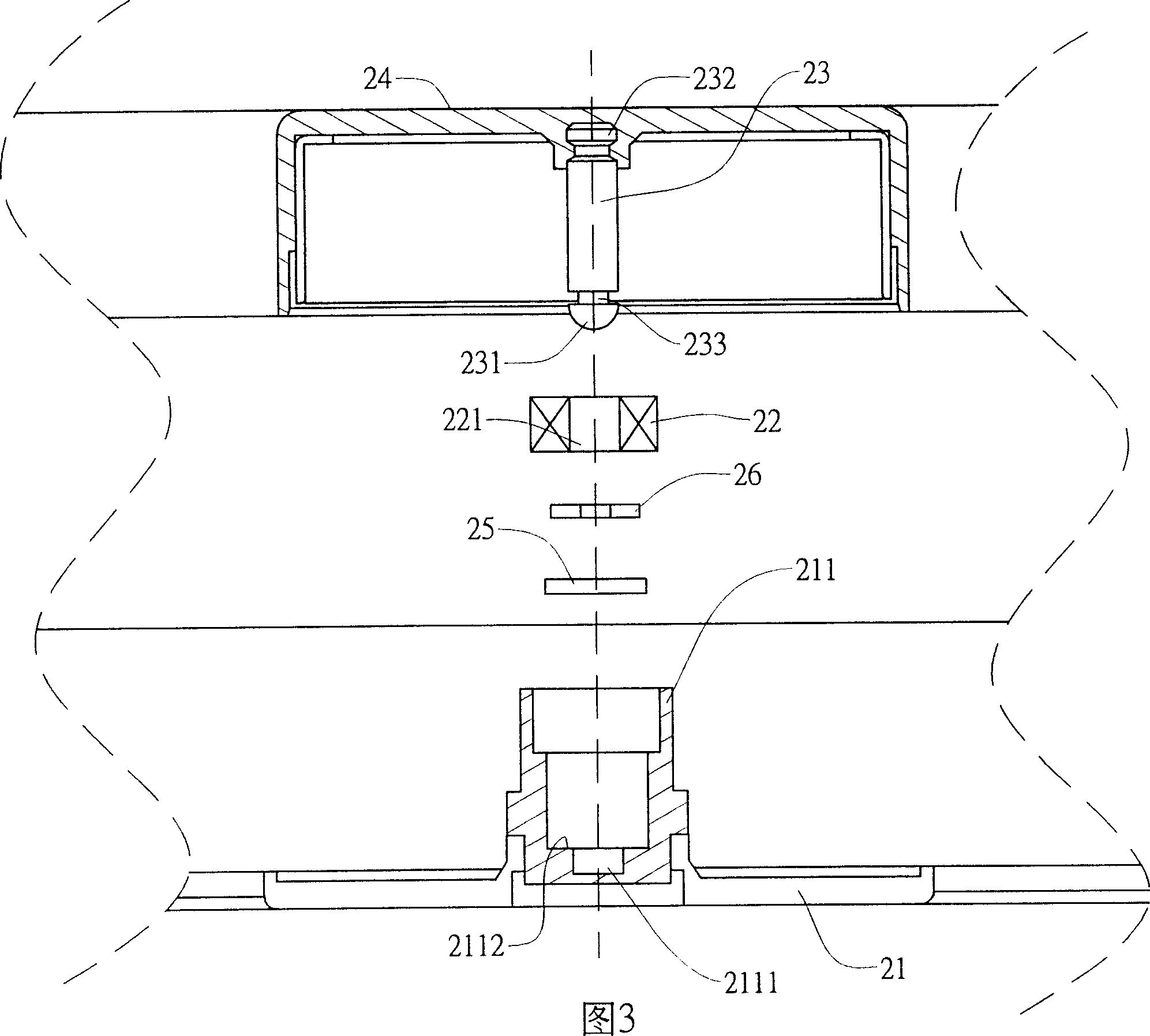

[0022] The present invention is a shockproof mechanism for motor bearings. Please refer to the first preferred embodiment of the present invention shown in FIGS. 3 to 5. As shown in FIGS. , a hollow shaft cylinder 211 is formed on it, a groove 2111 is formed at the inner bottom of the shaft cylinder 211, the groove 2111 has a convex portion 2112, and at least one shock absorbing component 25 is arranged on the convex portion 2112, and a A bearing 22 having a through hole 221 is arranged in the shaft cylinder 211, and a shaft 23, one end 232 of the shaft 23 is connected to a fan wheel 24, and the other end 231 of the shaft 23 has a neck 233 and runs through the shaft. The through hole 221 of the bearing 22 is fastened to the neck 233 through a snap ring 26, so that the shaft center 23 is pivotally arranged in the shaft tube 211, preventing the shaft center 231 from falling off from the shaft tube 221, and making the shaft center 23 The other end 231 of the shaft contacts the sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com