Time-sharing starting method of three-phase AC asynchronous motor

An asynchronous motor and three-phase AC technology, which is applied to the starter of a single multi-phase induction motor, motor generator/starter, etc., can solve the problems of complicated, inconvenient use, and high cost of starting equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention is further explained as follows with reference to accompanying drawing in conjunction with specific embodiment:

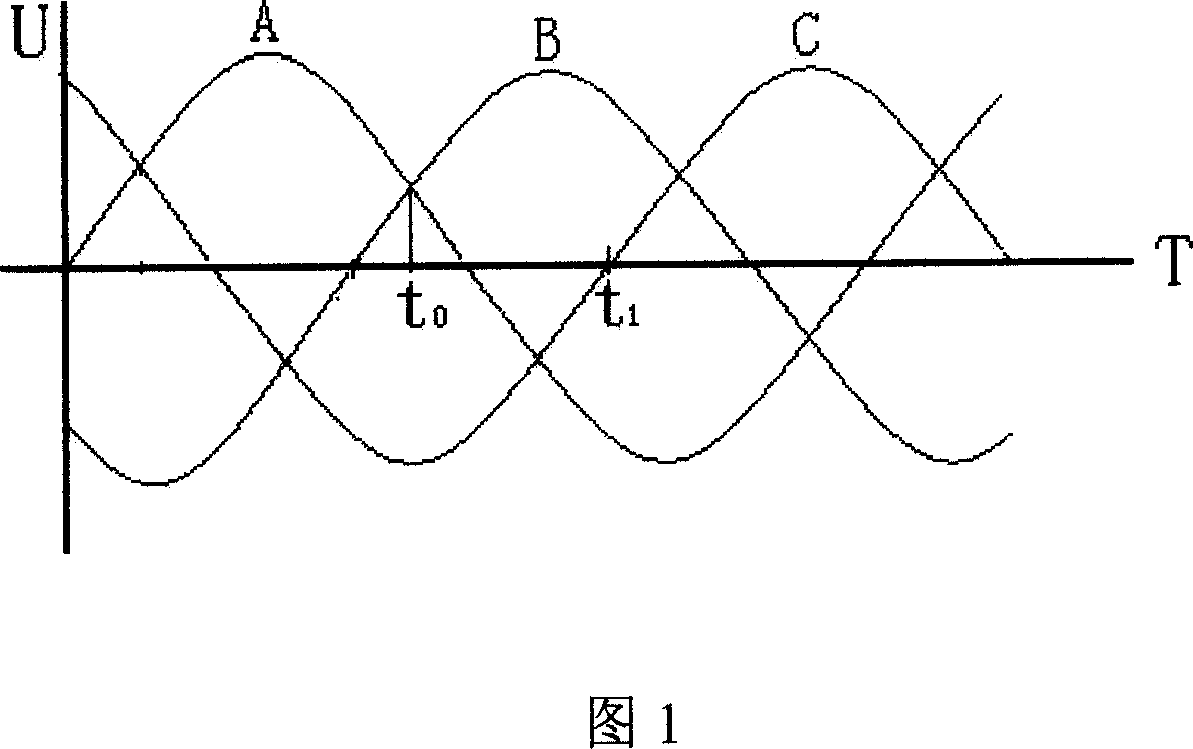

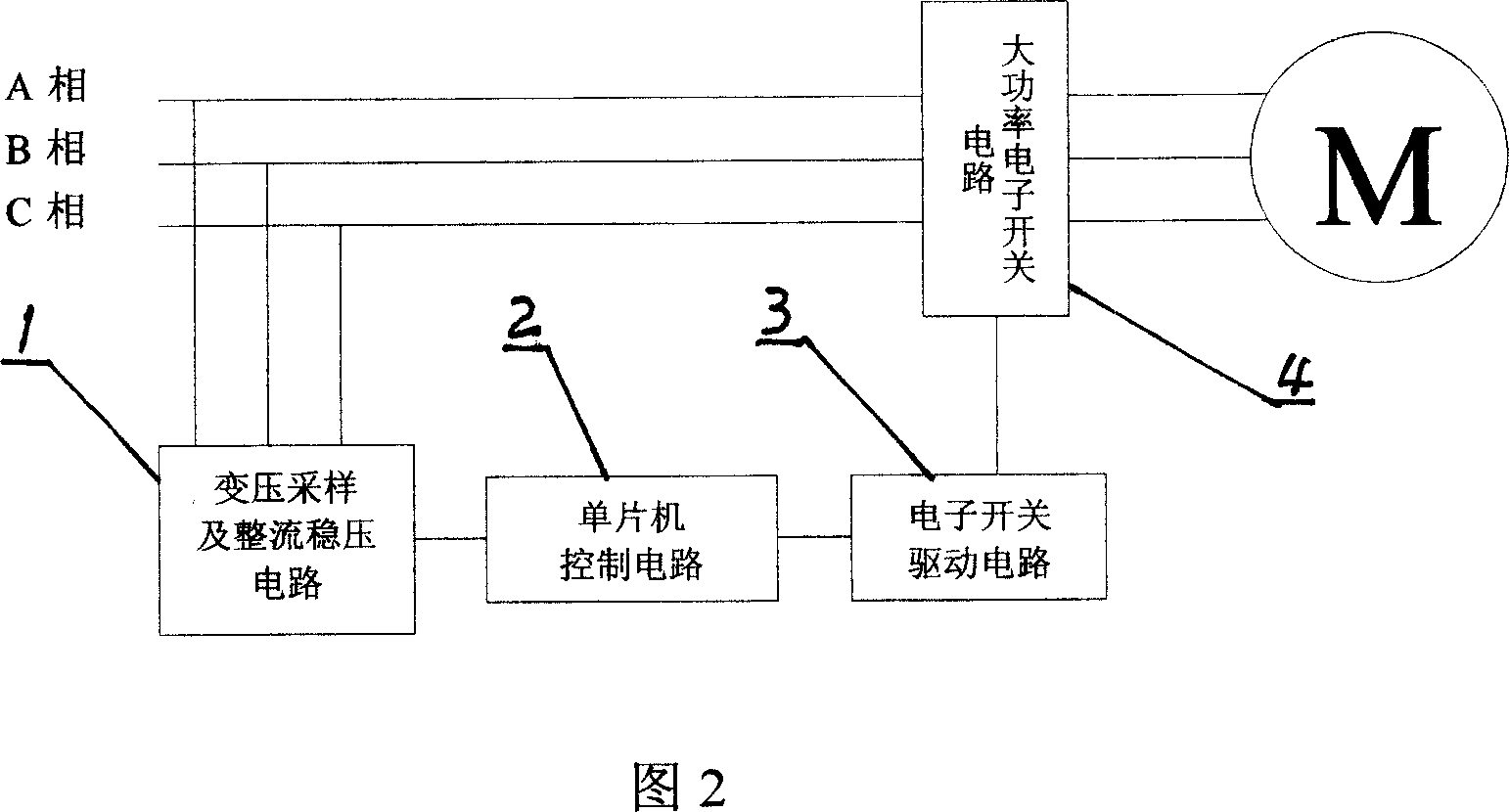

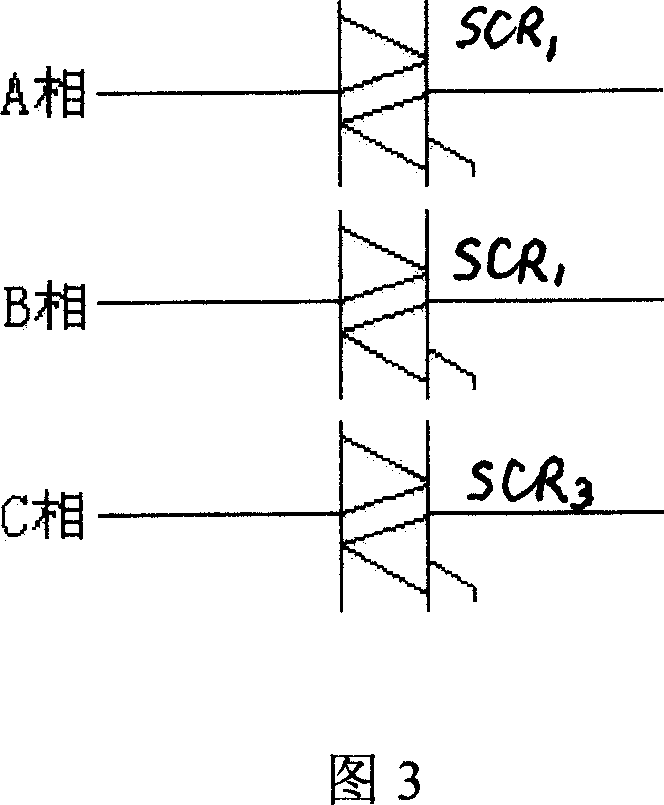

[0010] A time-sharing starting method for a three-phase asynchronous motor, which is a starting method for controlling voltage. When the three-phase asynchronous motor starts, the time-sharing control three-phase power supply AC sine wave voltage is applied to the input end of the motor, see Figure 1, Take any two phases of the three-phase voltage of A, B, and C, for example, the instantaneous voltage difference ΔU between the two phases of A and B AB is zero time, in the figure t 0 time, connect the two-phase voltage U AB Applied to the corresponding A and B two-phase input terminals of the motor, at this time t 0 , the other phase voltage C does not turn on the motor, and after a delay of Δt until the instantaneous voltage value of the other phase C is zero, t in the figure 1 At this time, the C-phase voltage is turned on, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com