Aquaculture sewage purifier using large-sized algae as fillings

A technology for aquaculture sewage and purification equipment, which is applied in biological water/sewage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc. It can solve problems such as reactors that have not been reported, so as to improve water quality and increase dissolved oxygen Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

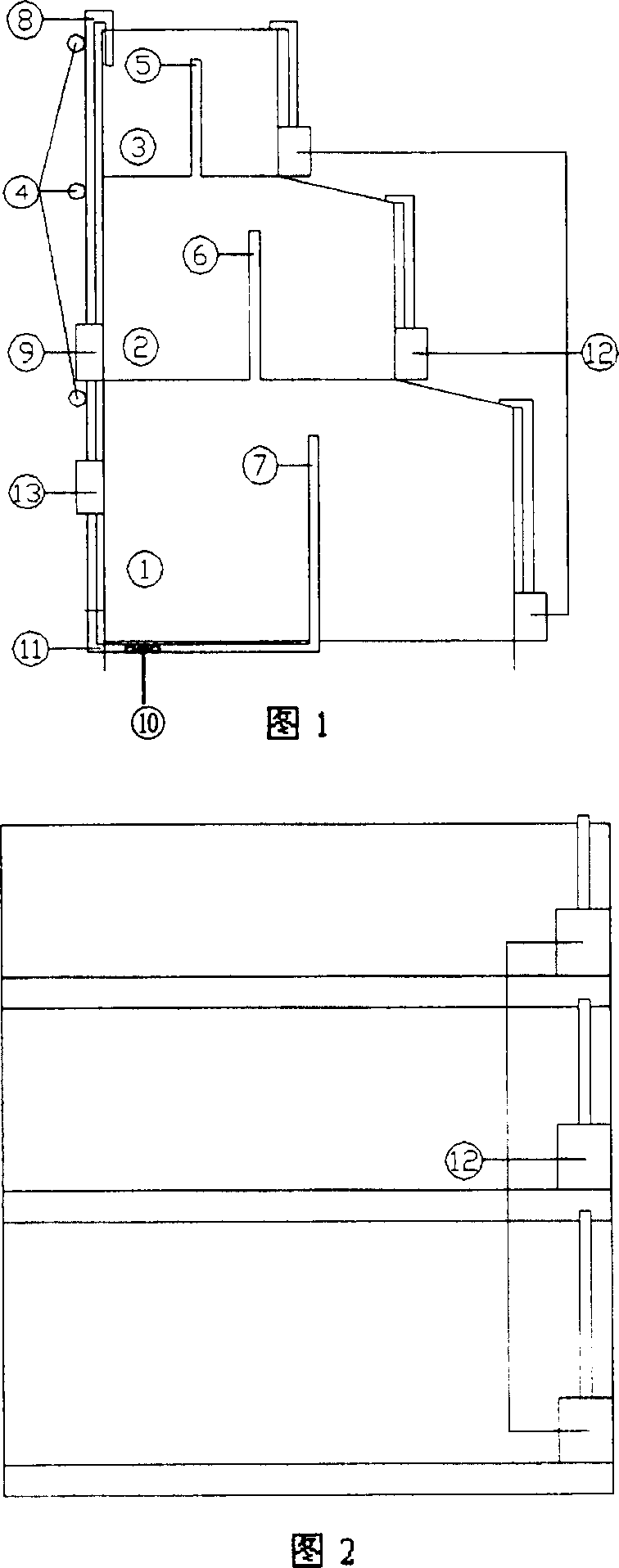

[0020] The aquaculture sewage enters the top glass box 3 from the main water inlet pipe 8 and fully contacts with the algae. Under the condition that the fluorescent lamp 4 is used as the light source and the air pump 12 is inflated, the metabolism and photosynthesis of the algae will be carried out more fully, and the sewage will pass through the middle of the glass box. The water outlet pipe 5 enters the middle glass box 2, and after being fully absorbed by the algae in the middle glass box 2, it enters the bottom glass box 1 through the water outlet pipe 6, and the water outlet pipe 7 of the bottom glass box 1 communicates with the total water outlet pipe 11. A refrigeration pump 13 and a water pump 9 are installed on the pipeline between the outlet pipe and the main water inlet pipe. The water in the main water outlet pipe 11 is lifted back to the main water inlet pipe 8 through the water pump 9. The refrigeration pump 13 is used for cooling sea water and can adjust the wate...

Embodiment 2

[0022] The difference from Example 1 is:

[0023] The culture solution enters the top floor glass box 3 from the main water inlet pipe 8 and fully contacts the algae. Under the condition that the fluorescent lamp 4 is used as a light source and the air pump 12 is inflated, the photosynthesis of the algae can be carried out more fully, and the algae metabolism is vigorous and grows faster. The culture solution enters the middle glass box 2 through the water outlet pipe 5 in the middle of the glass box. After fully contacting the algae in the middle glass box 2, it enters the bottom glass box 1 through the water outlet pipe 6. The water outlet pipe 7 of the bottom glass box 1 is connected with the main water outlet pipe. 11 communicates, the water in the total outlet pipe 11 lifts the culture solution back to the total water inlet pipe through the water pump 9 to enter a new round of circulation, and regularly replaces part of the culture solution during the cultivation process. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com