Automatic opening-closing unit of movable head cover for locomotive

A technology of automatic opening and closing device and locomotive, which is applied in railway car body, transportation and packaging, railway car body parts, etc. Avoid sagging effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

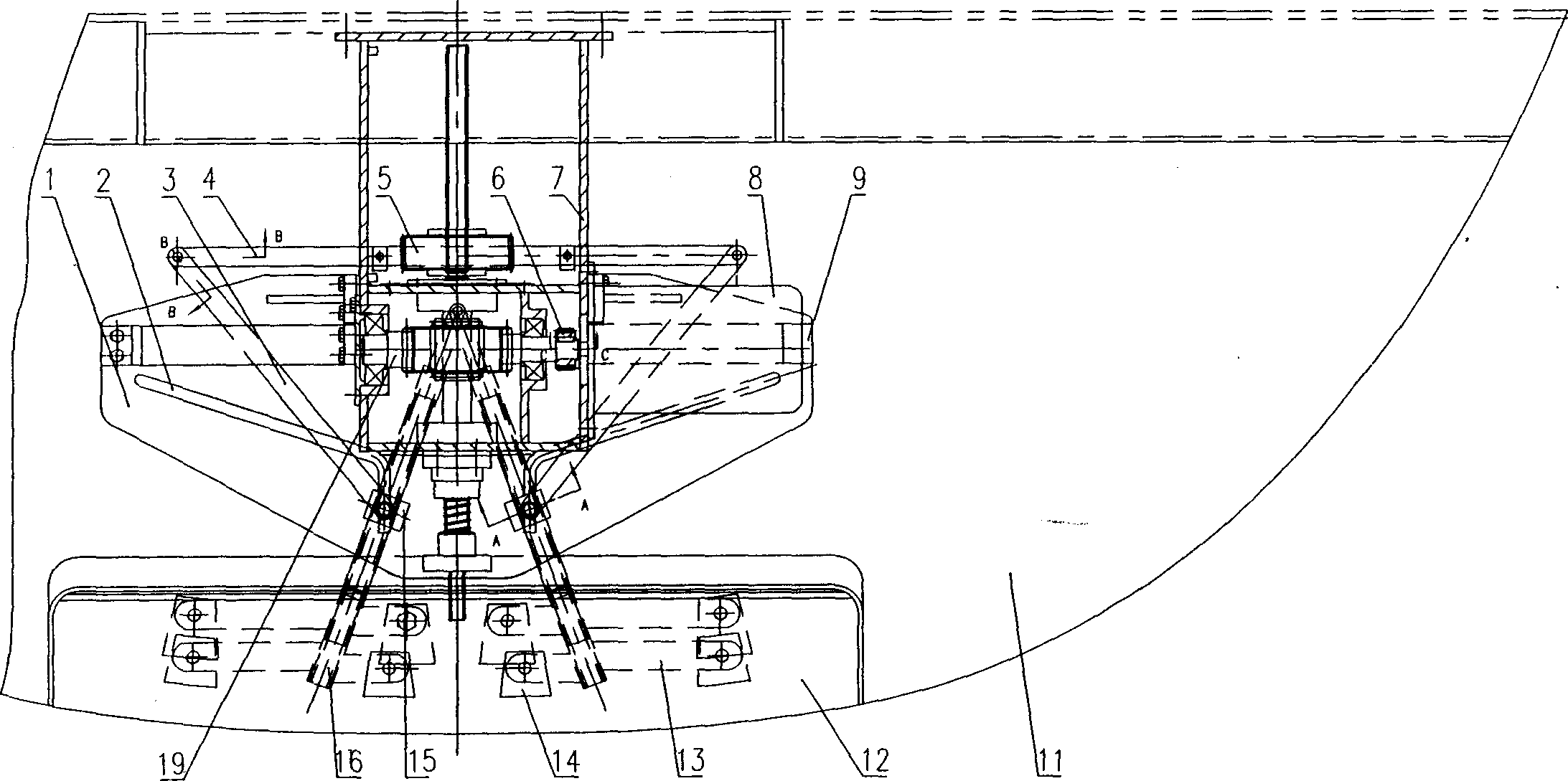

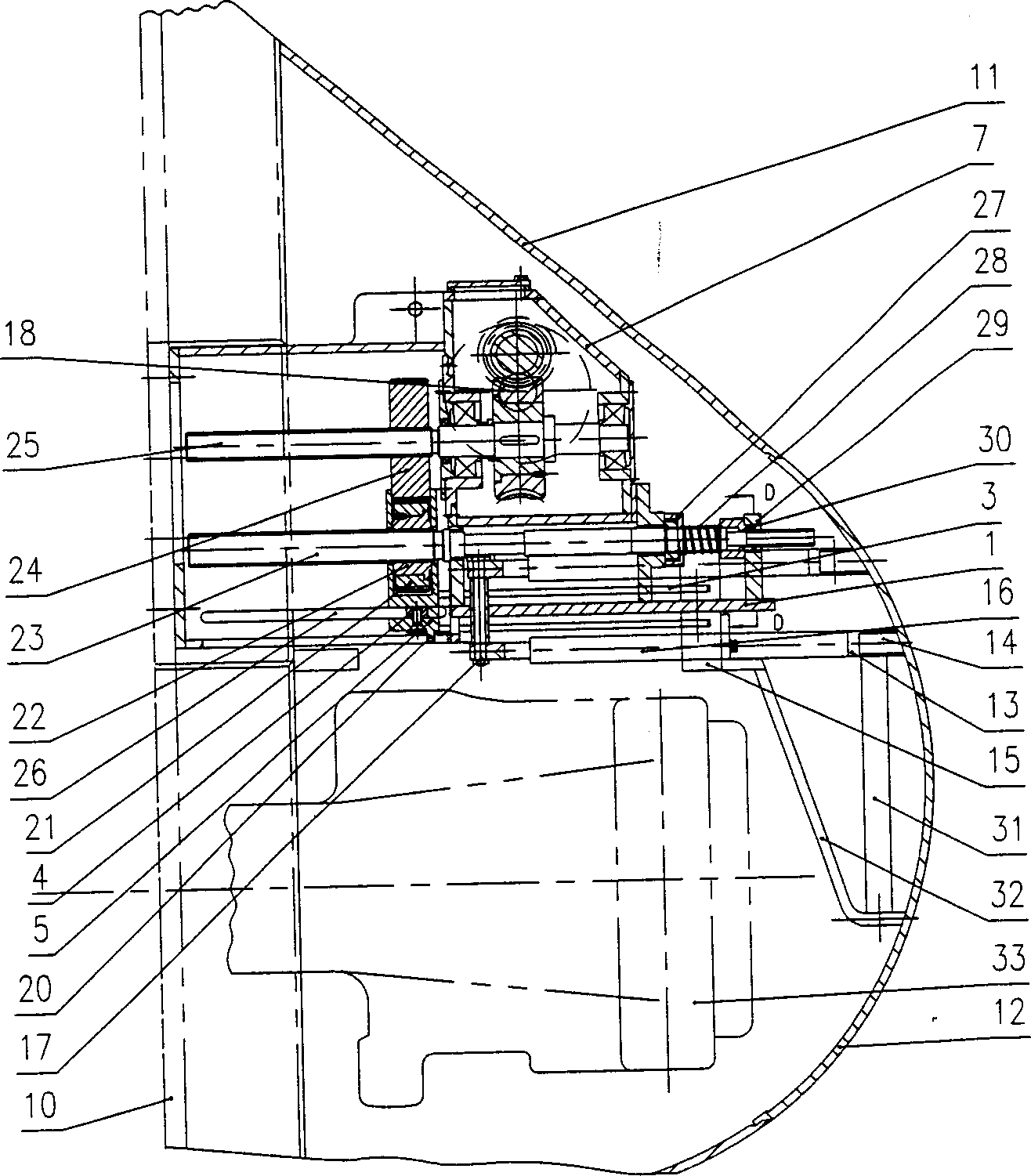

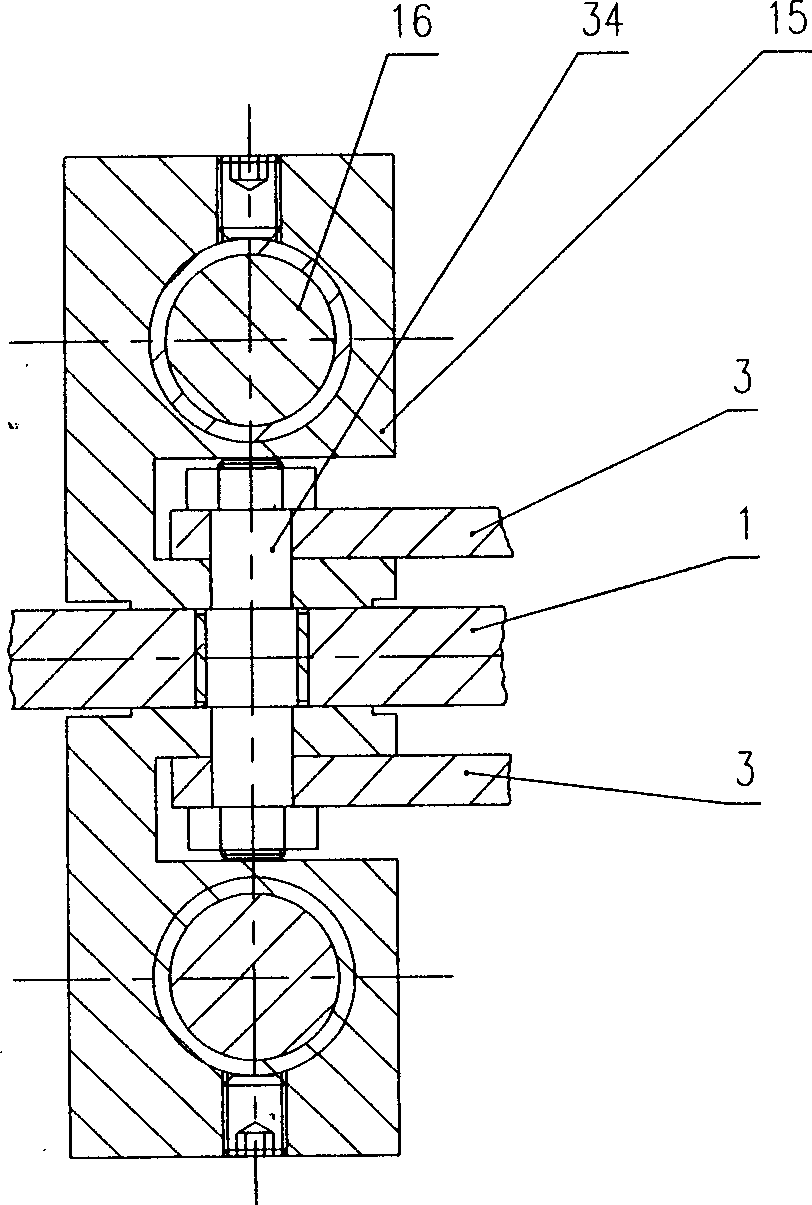

[0017] from figure 1 , figure 2 As can be seen, the present invention is positioned on the coupler 33, and is made of fixed headstock 11, two movable headstocks 12, two sets of support mechanisms, two sets of slide bar mechanisms, guide mechanisms, connecting rod mechanisms, transmission mechanisms, and electric manual switching mechanisms. Fixed head cover 11 links to each other with car body, and the edge that it joins with movable head cover 12 has sunken platform; Corresponding to the fixed hood 11 and corresponding to each other, to ensure that the movable hood 12 fits well with the fixed hood 11 when it is closed, and to avoid the vibration of the movable hood 12 when the locomotive is running; Headstock 12 links to each other, and they all are made of two pairs of connecting supports 14 and two poles 13, and two pairs of connecting supports 14 points upper and lower two rows are fixed on the inboard of movable hood 12, two poles 13 two ends Each is connected with a p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com