Coaxial line plug-in connection with integrated galvanic separation

A technology of plug connection and coaxial line, applied in the direction of connection device, two-part connection device, and parts of connection device, etc., can solve problems such as difficulty in equipment, and achieve the effect of small assembly cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

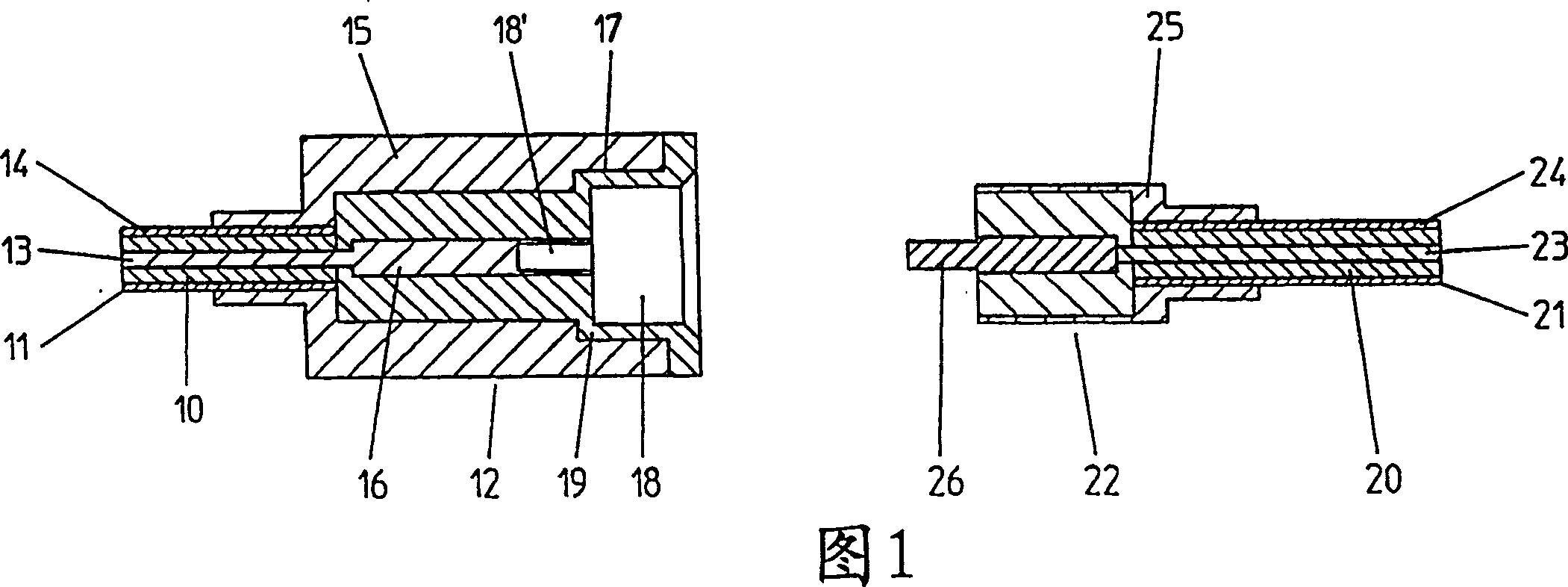

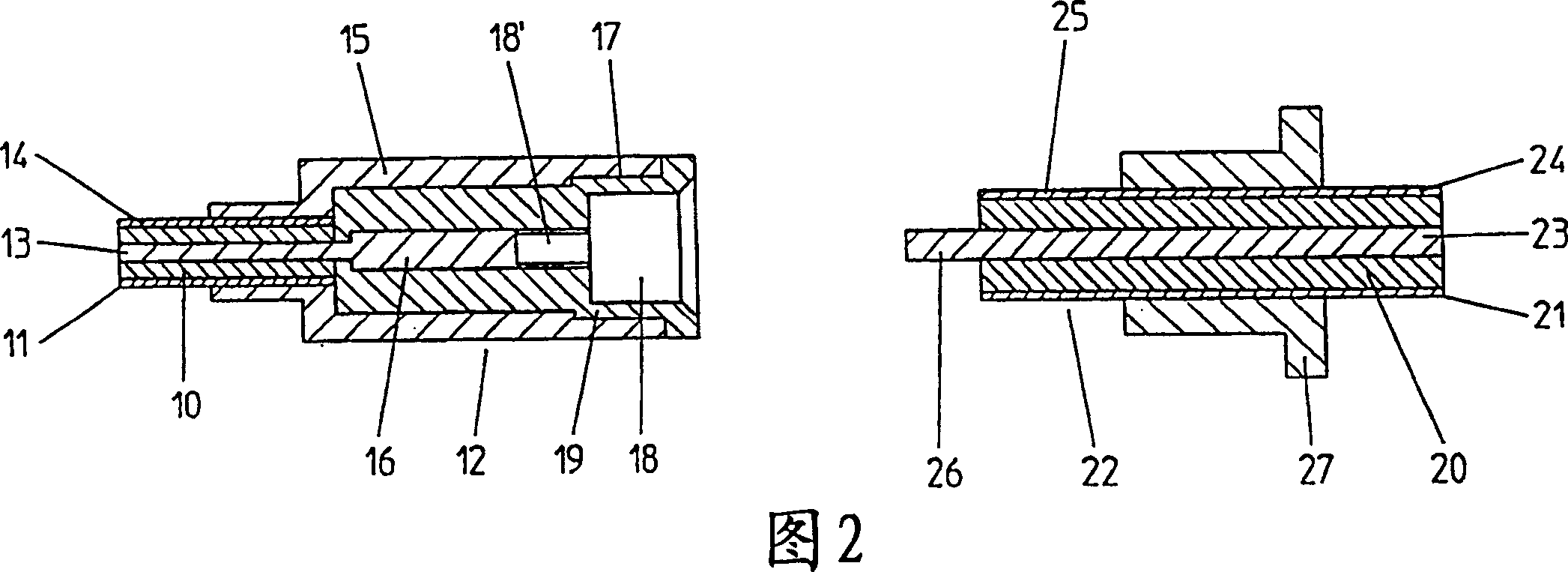

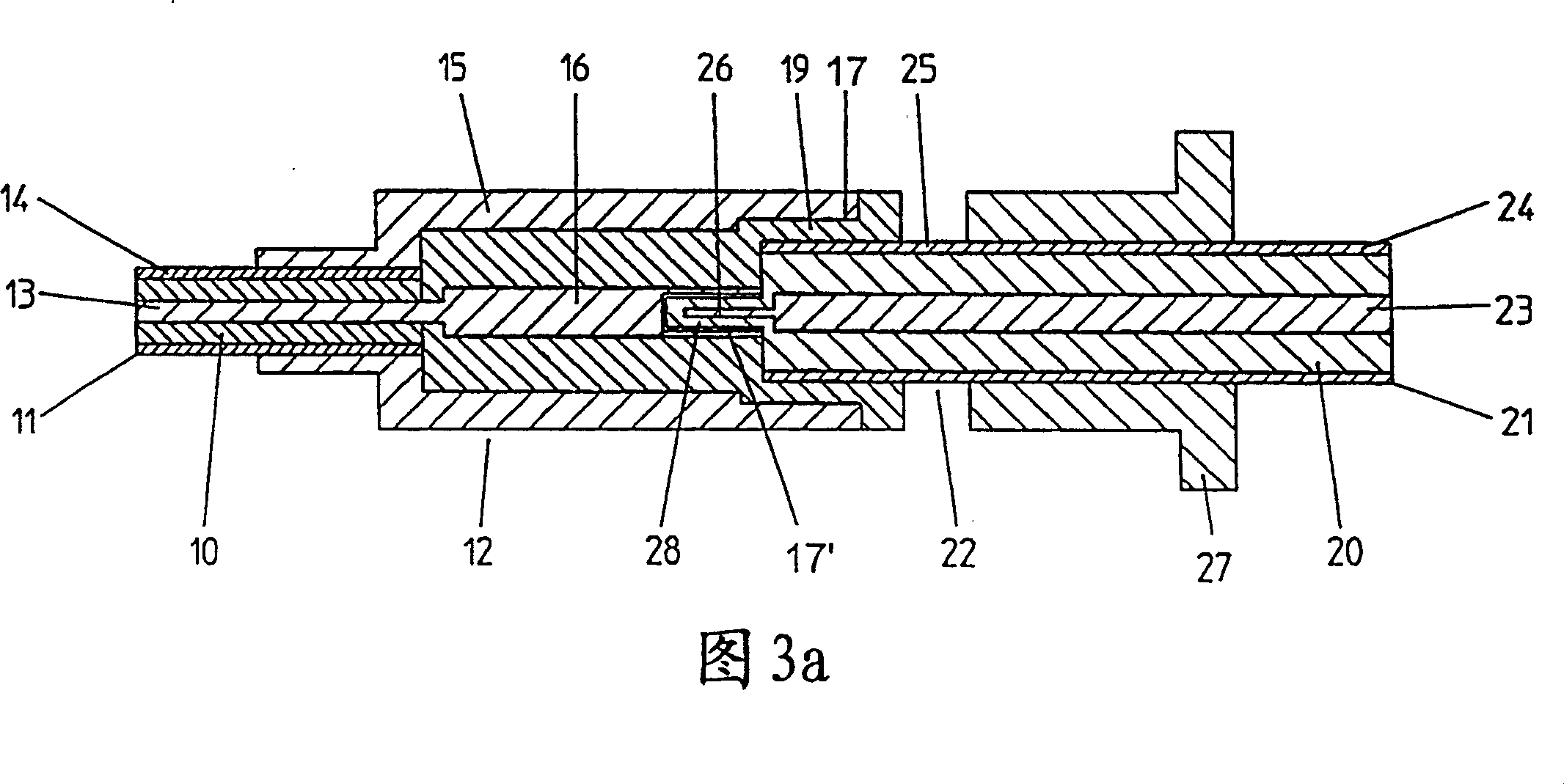

[0033] Fig. 1 is a longitudinal sectional view of a first embodiment of a plug connection according to the invention. The plug connection consists of a socket 12 and a plug 22 . Connected to the socket 12 is a coaxial line 11 which is connected to the transmitting and receiving unit. The coaxial line 11 consists of an outer conductor 14 as a shielded conductor and an inner conductor 13 for transmitting signals. The inner conductor 13 and the outer conductor 14 are insulated from each other by a dielectric 10 . The outer conductor 14 of the coaxial line is connected to the outer conductor of the socket 15 . The inner conductor of the coaxial line is connected to the inner conductor of the socket 16 .

[0034] The coaxial line 21 likewise consists of an inner conductor 23 for transmitting signals and an outer conductor 24 as a shielding conductor, which are insulated from each other by a dielectric 20 . The outer conductor 24 is connected to the outer conductor 25 of the plu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com