Fine grained aluminum ingot and method for manufacturing the same

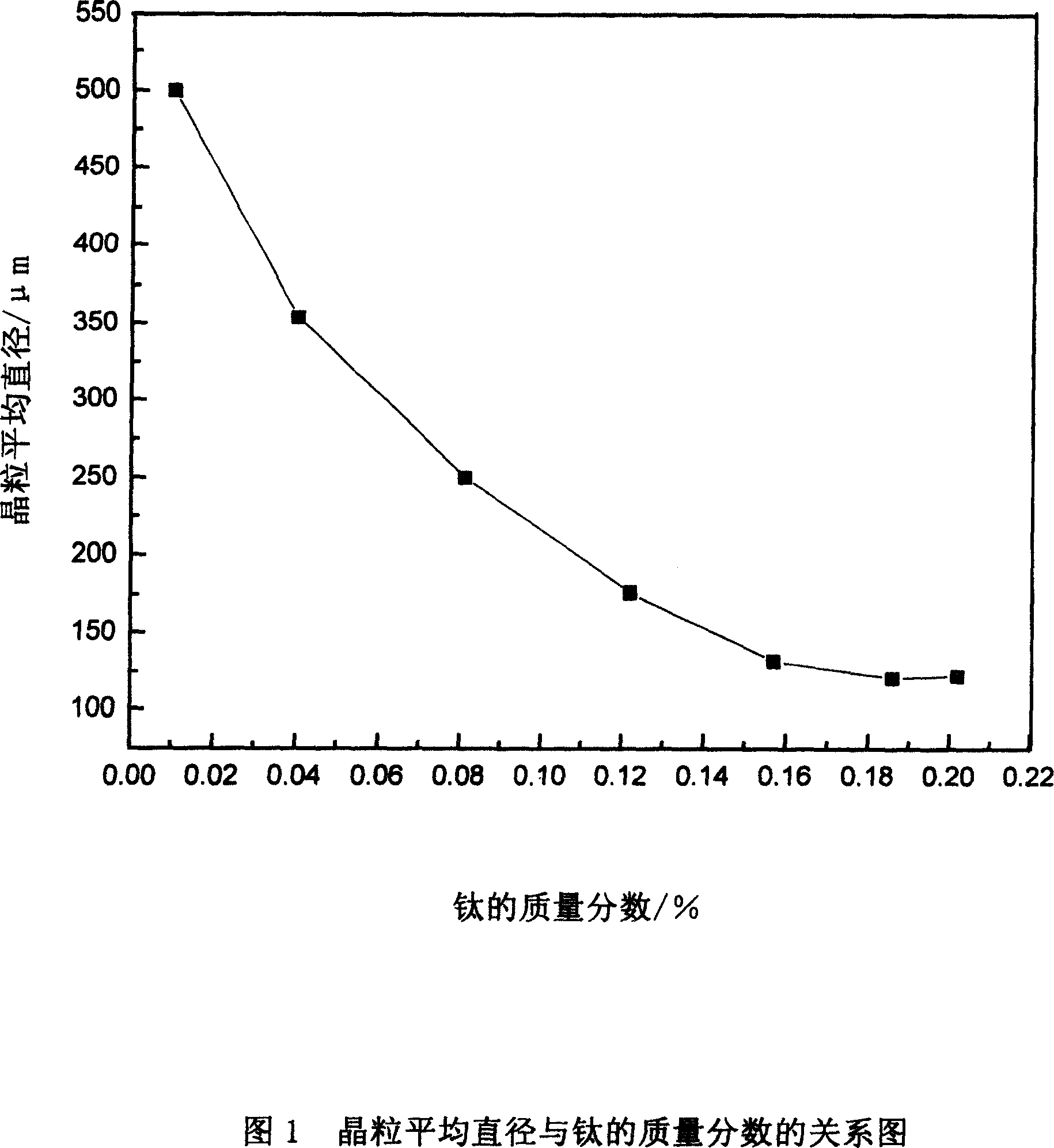

An aluminum ingot and fine-grain technology, applied in the field of aluminum alloy manufacturing, can solve the problems of source limitation, the number of days and methods of titanium oxide addition, and the inability to guarantee the impurity content of low-titanium aluminum alloys.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

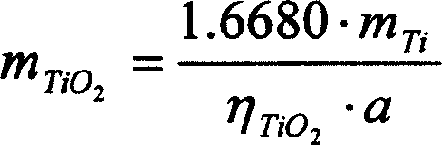

Method used

Image

Examples

Embodiment 1

[0049] By adding titanium dioxide pigment (TiO 2 98%) and alumina to produce a fine-grained aluminum ingot with a titanium mass fraction of 0.03%. The titanium dioxide pigment is added in one day, and the titanium dioxide pigment should be added to the feed box of the electrolytic cell after the aluminum is tapped, and fully mixed with the alumina. The mass fraction of the chemical composition of the mixture of titanium dioxide pigment and aluminum oxide used for electrolysis is:

[0050] Alumina (Al 2 o 3 ) 98.185%

[0051] Titanium oxide (TiO 2 ) 0.214%

[0052] Impurities in alumina 1.596%

[0053] Impurities in titanium oxide 0.005%

[0054] The mass fraction of each component of the electrolyte in the cryolite system is:

[0055] Molecular ratio (NaF:AlF 3 ) 2.36

[0056]Sodium Fluoride (NaF) 46.97%

[0057] Aluminum fluoride (AlF 3 ) 39.81%

[0058] Calcium Fluoride (CaF 2 ) 3.56%

[0059] Magnesium fluoride (MgF 2 ) 1.14%

[0060] The electrolytic proce...

Embodiment 2

[0070] By adding natural rutile concentrate (TiO 2 94%) and alumina to produce a fine-grained aluminum ingot with a mass fraction of titanium of 0.10%. The natural rutile concentrate is added in two days, and should be added to the feed box of the electrolytic cell after the aluminum is tapped, and fully mixed with the alumina.

[0071] The mass fraction of each component of the electrolyte in the cryolite system is:

[0072] Molecular ratio (NaF:AlF 3 ) 2.39

[0073] Sodium Fluoride (NaF) 46.96%

[0074] Aluminum fluoride (AlF 3 ) 39.34%

[0075] Calcium Fluoride (CaF 2 ) 3.90%

[0076] Magnesium fluoride (MgF 2 ) 0.90%

[0077] The electrolytic process parameters are:

[0078] Electrolysis temperature 948℃

[0079] Electrolyzer working voltage 4.28V

[0080] Aluminum liquid height 19cm

[0081] Electrolyte height 23cm

[0082] The mass fraction target value of titanium in molten aluminum on the first day is 0.05%. Natural rutile concentrate (TiO 2 94%) and th...

Embodiment 3

[0101] By adding artificial rutile (TiO 2 90%) and alumina to produce a fine-grained aluminum ingot with a titanium mass fraction of 0.08%. The synthetic rutile was added over two days and mixed well with the alumina.

[0102] The mass fraction of each component of the electrolyte in the cryolite system is:

[0103] Molecular ratio (NaF:AlF 3 ) 2.40

[0104] Sodium Fluoride (NaF) 47.92%

[0105] Aluminum fluoride (AlF 3 ) 39.99%

[0106] Calcium Fluoride (CaF 2 ) 3.86%

[0107] Magnesium fluoride (MgF 2 ) 2.14%

[0108] The electrolytic process parameters are:

[0109] Electrolysis temperature 940℃

[0110] Electrolyzer working voltage 4.41V

[0111] Aluminum liquid height 20cm

[0112] Electrolyte height 21cm.

[0113] The mass fraction target value of titanium in molten aluminum on the first day is 0.05%. Artificial rutile (TiO 2 90%) and the mass fraction of the chemical composition of the mixture of aluminum oxide is:

[0114] Alumina (Al 2 o 3 ) 97.854%...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com