Short inking unit

An ink and coating roller technology, applied in printing, rotary printing presses, printing presses, etc., can solve the problems of difficulty in forming ink/wetting solution emulsion, difficulty in changing modes, and small number of pinch points, etc., which can affect ink consumption, The effect of uniform height and avoidance of ghosting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

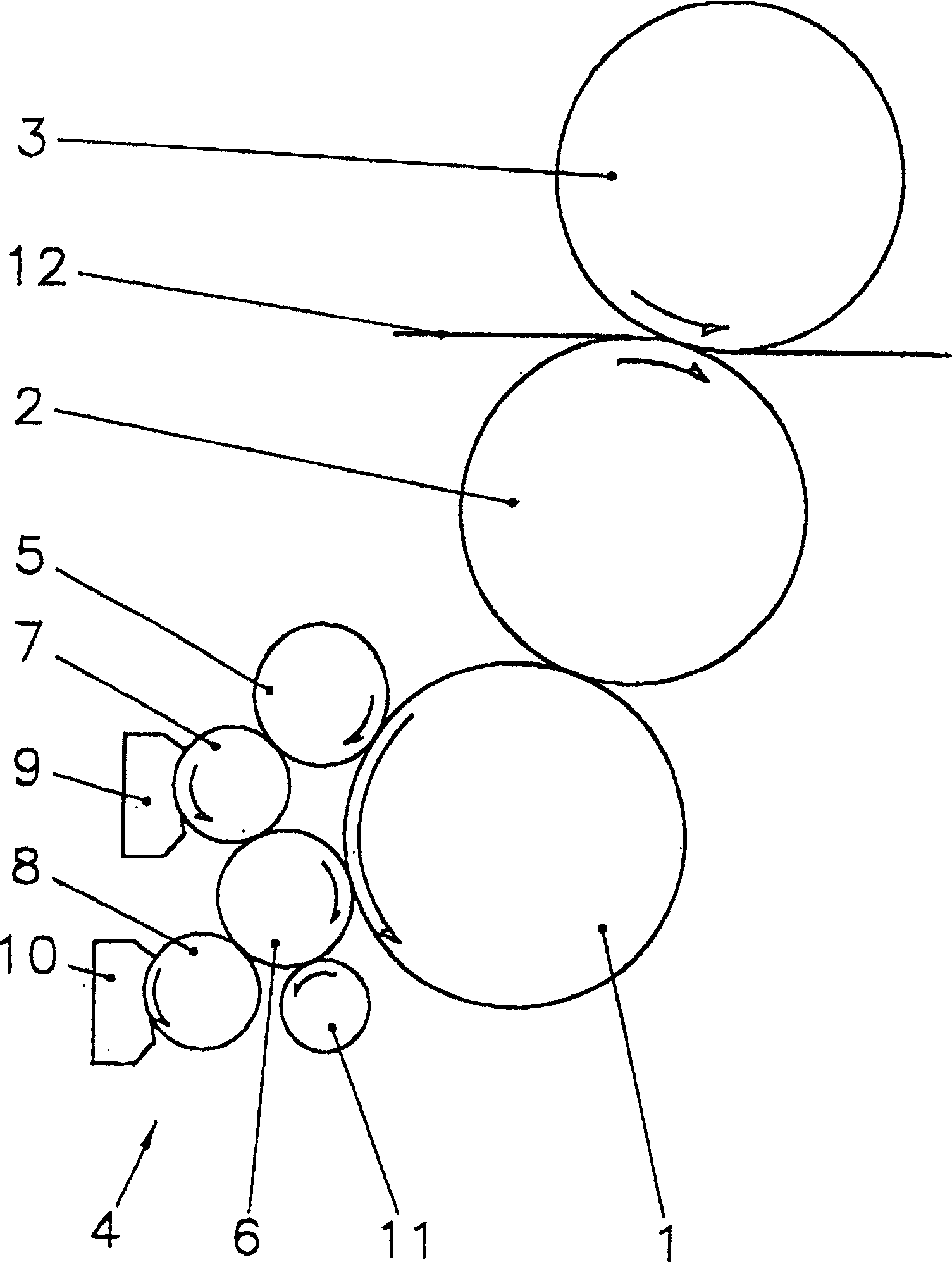

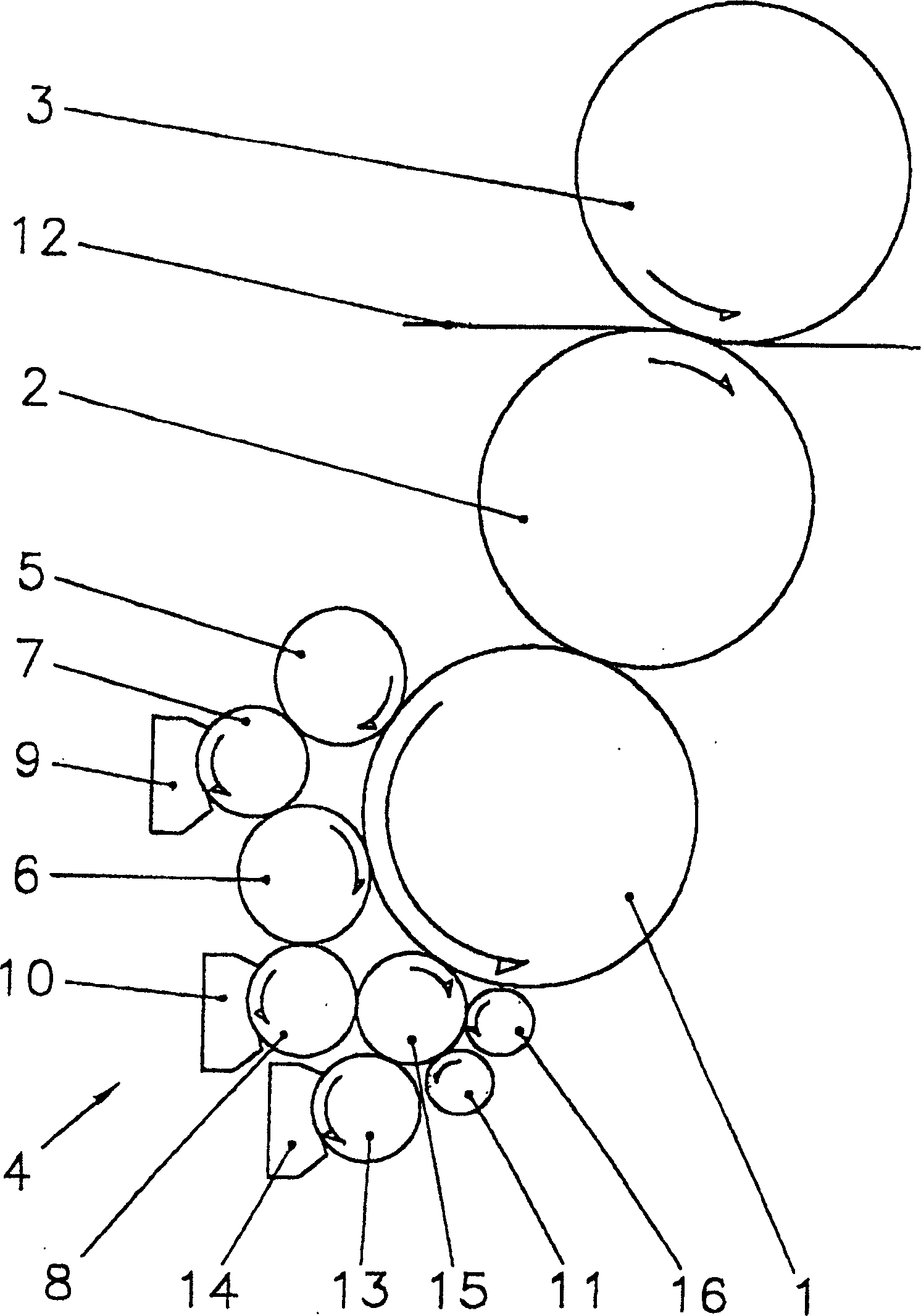

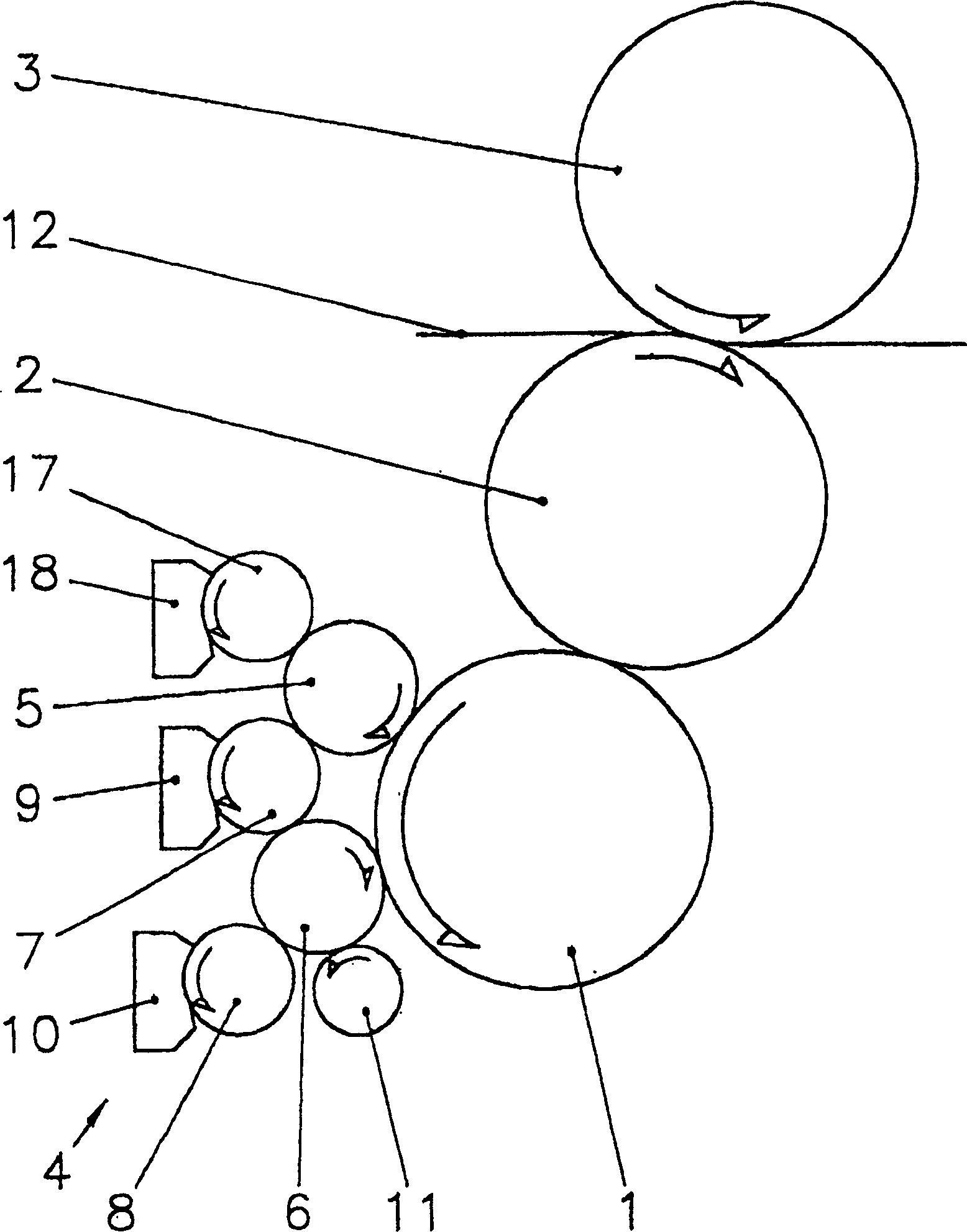

[0017] The main field of application of the invention lies in lithographic printing units for indirect or direct lithography, in the form of offset printing units for indirect or direct offset printing. The basic structure and method of operation of a printing unit of this type are known per se and therefore no further explanation is required here.

[0018] Figure 1-4 The offset printing unit shown comprises a printing cylinder 1 , a transfer cylinder 2 and an impression cylinder 3 . The printed material web 12 passes between the transfer cylinder 2 and the embossing cylinder 3 . In the case of wet offset printing, ink and dampening solution are applied to the printing form cylinder 1 . The inking unit 4 is arranged to supply ink. A wetting unit (not shown in more detail) may be arranged to supply a wetting solution. Wetting unit is omitted in case of waterless offset printing.

[0019] The inking unit 4 is configured as a short inking unit. It comprises a plurality of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com