Fuel-jetting device

A fuel injection device and injection hole technology, which can be applied to fuel injection devices, special fuel injection devices, fuel injection devices with wear reduction measures, etc., can solve problems such as poor durability, and achieve the effect of overall compactness and light stress concentration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] (first embodiment)

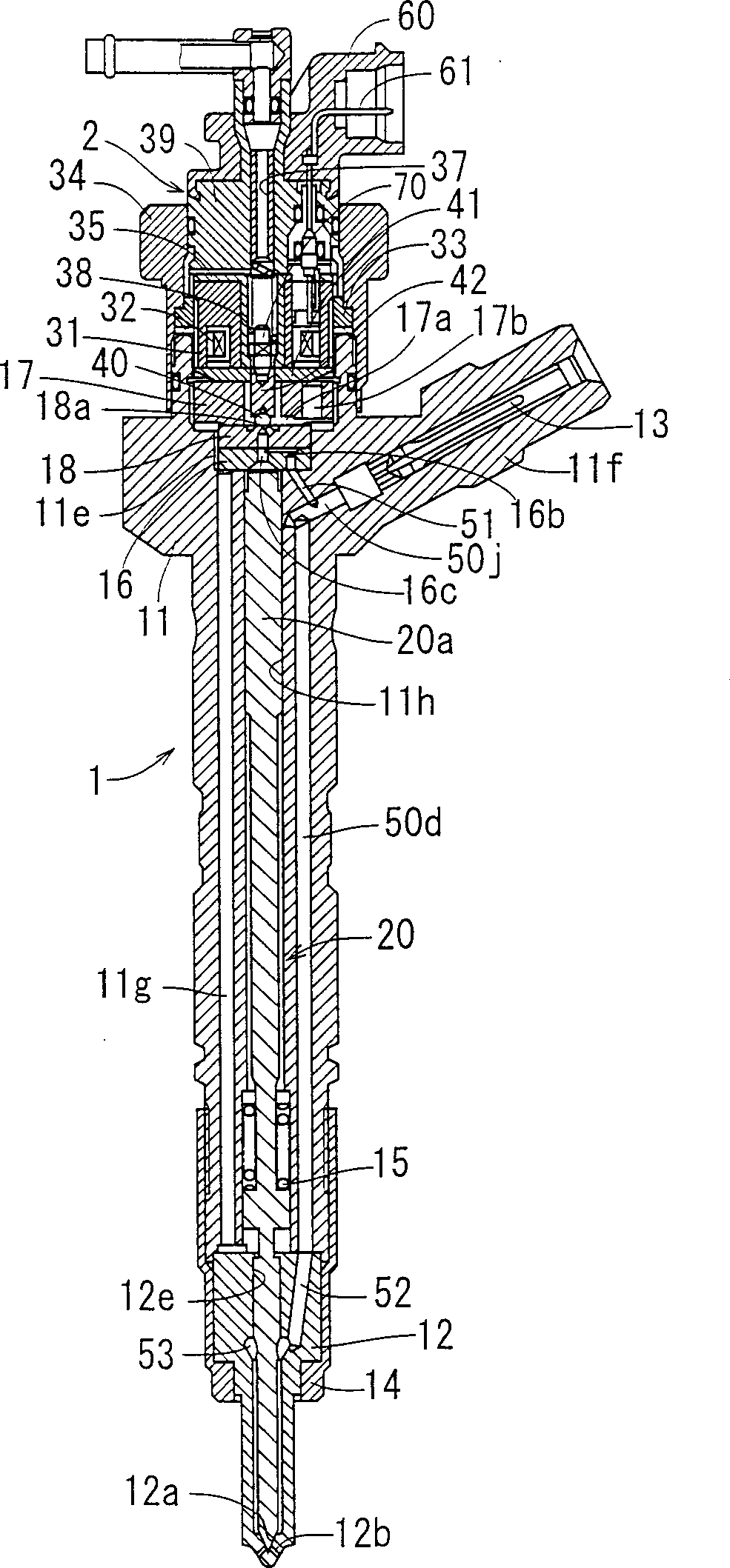

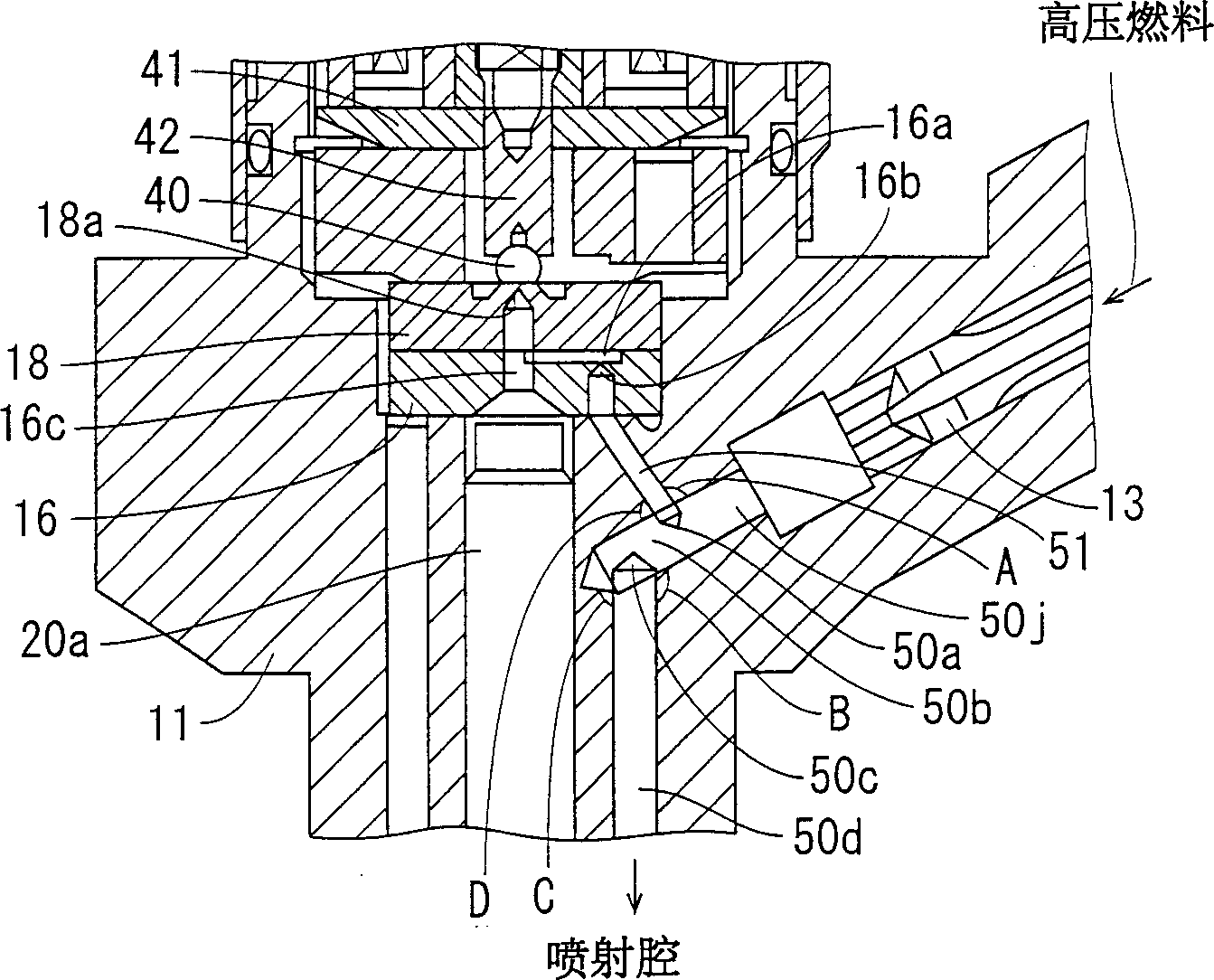

[0022] Refer below figure 1 and 2 The injector 1 as the fuel injection device according to the first embodiment is described. The injector 1 is inserted and mounted on an engine head of an engine (not shown), and directly injects high-pressure fuel supplied from a common rail (not shown) into each cylinder of the engine.

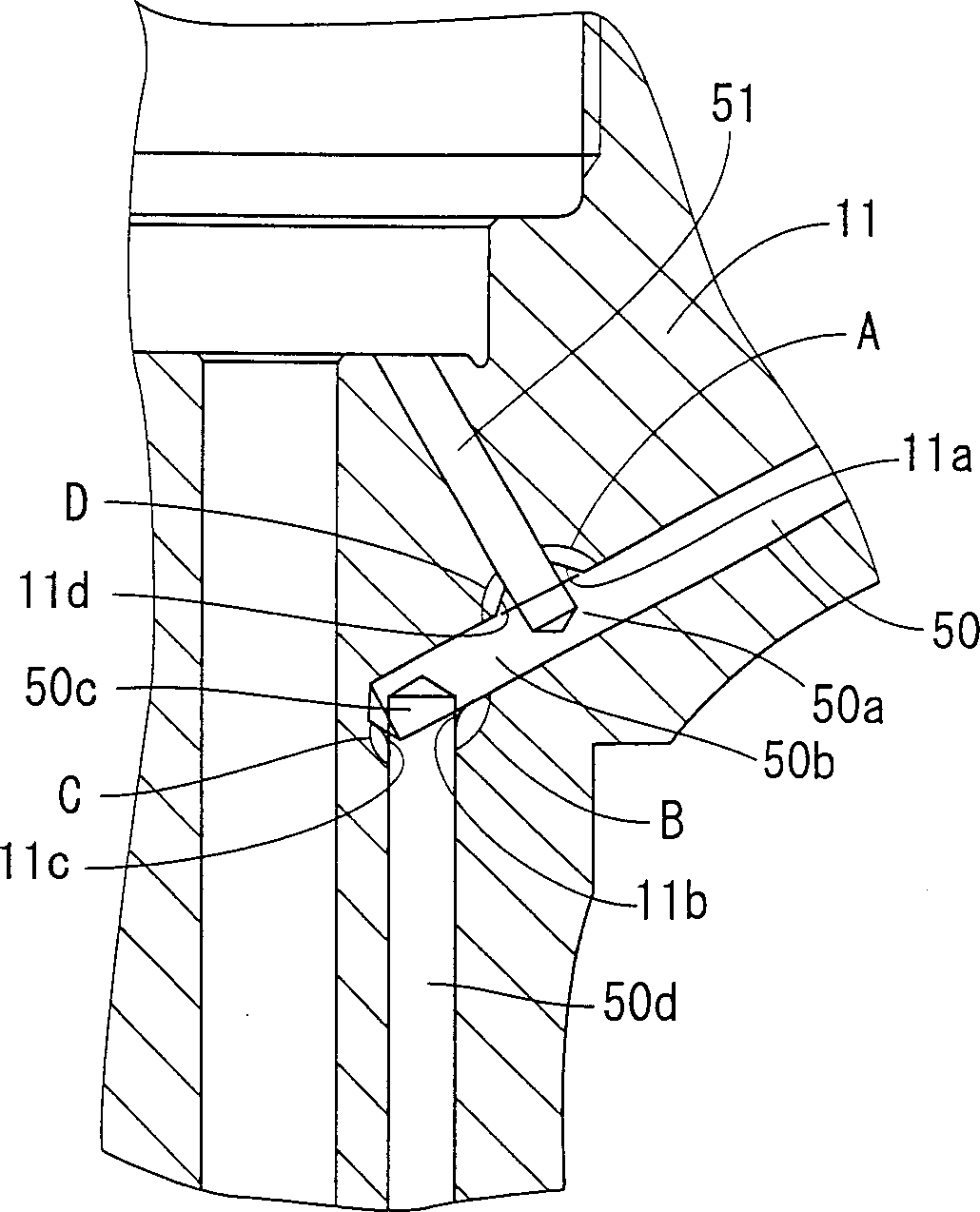

[0023] A holder body 11 is provided with a needle housing hole 11h for slidably receiving a nozzle valve member (valve member) 20 . The holder body 11 is also provided with an inlet portion 11f extending to the central axis of the holder body 11 at an angle of 61.5°. A rod filter 13 is arranged in the inlet portion 11f. The holder body 11 is provided with a vertical hole 50d at a position radially outward of the needle valve receiving hole 11h. The upper end of the vertical hole 50d communicates with a first inclined hole 50j formed in the inlet portion 11f. The lower end of the vertical hole 50d opens on the lower end surfa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com