Structures which can be dismantled and folded, consisting of interconnecting tubular elements

A technology of tubular components and components, applied in the field of foldable structures, which can solve the problems of heavy assembly operations, long time and complexity of disassembly and installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

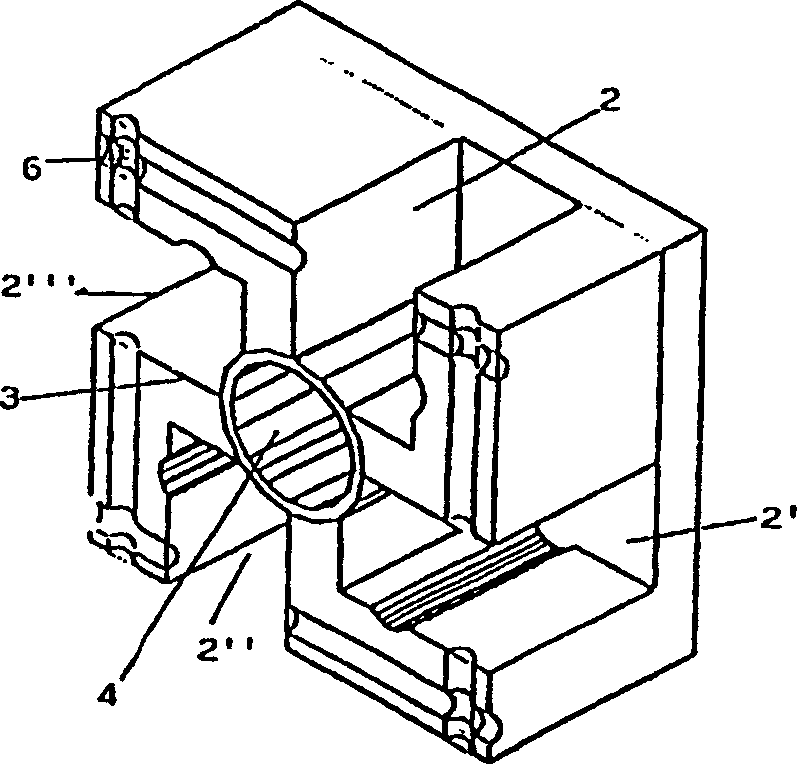

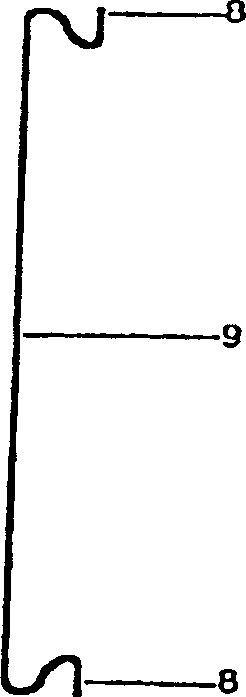

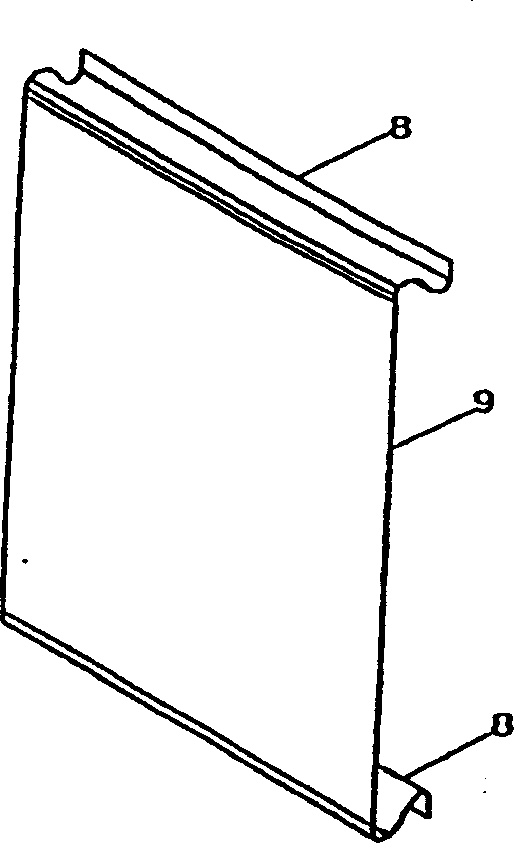

[0023] refer to figure 1 To figure 4, the universal joint has four grooves 2, 2', 2", 2'' on a larger surface that coincides with the sides, so that it can receive a tubular member that is not shown in the figure and that extends articulated On the surface 3 of the universal joint with four grooves (2, 2', 2", 2''), there is an opening 4 for fixing the end of the tubular extension member 5, and another not shown in the figure with the corresponding The tubular member connected by the universal joint can slide in the opening 4. Along the edge of said face of the universal joint is a groove 6 constituting the base for receiving the end 8 of a spring 9 as shown in FIG. 4 .

[0024] The two ends of the spring 9 are embedded in grooves on the non-matching surfaces in the two joints of the two overlapping members so that the coupled members remain fixed. After the member is inserted into said groove by the end 8 of the inverted spring 9, the spring is easily inserted and remains l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com