C-shaped profile and partition comprising a C-shaped profile

A profile and side technology, applied in the field of C-profiles, can solve the problems of not increasing, increasing manufacturing costs, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

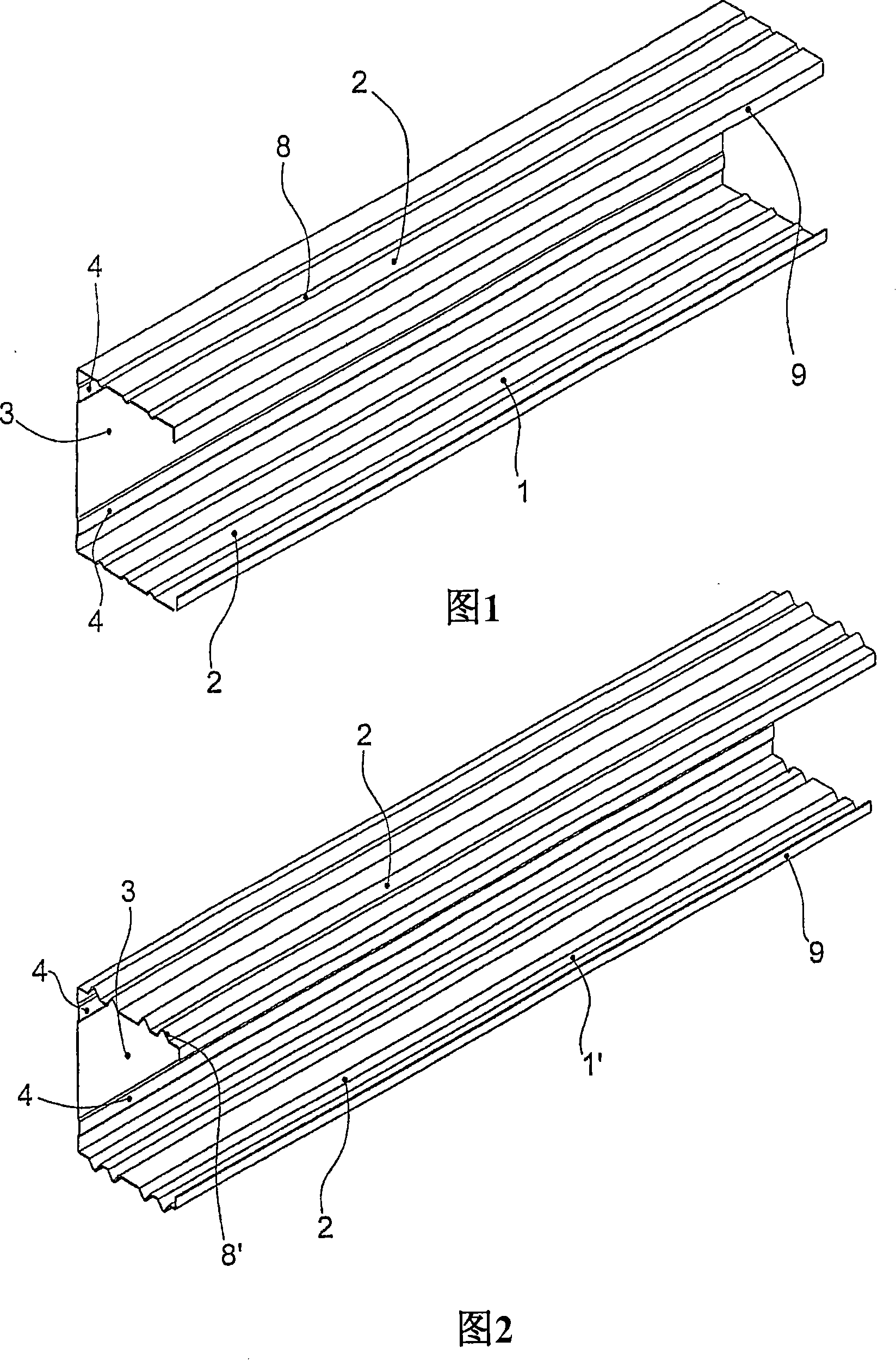

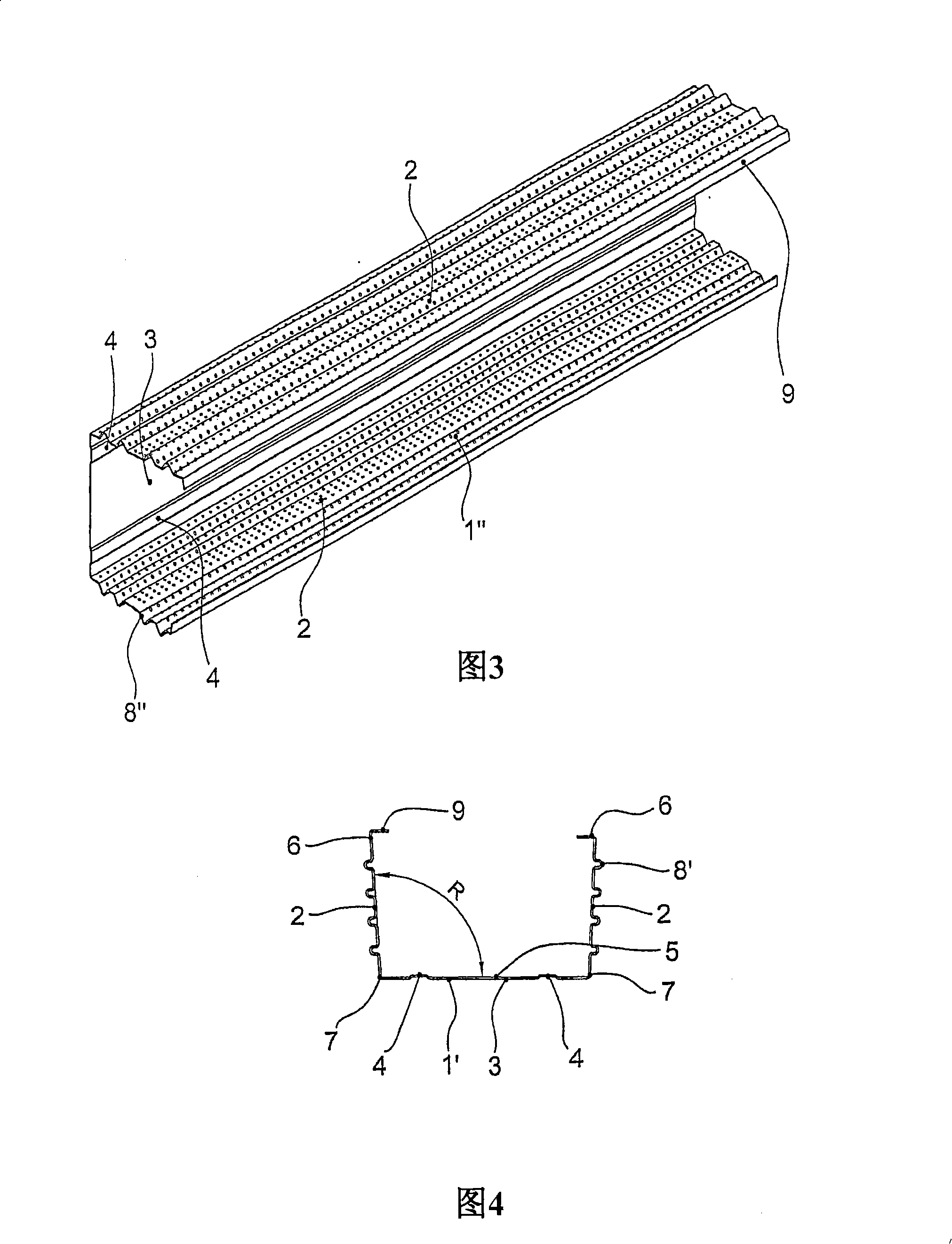

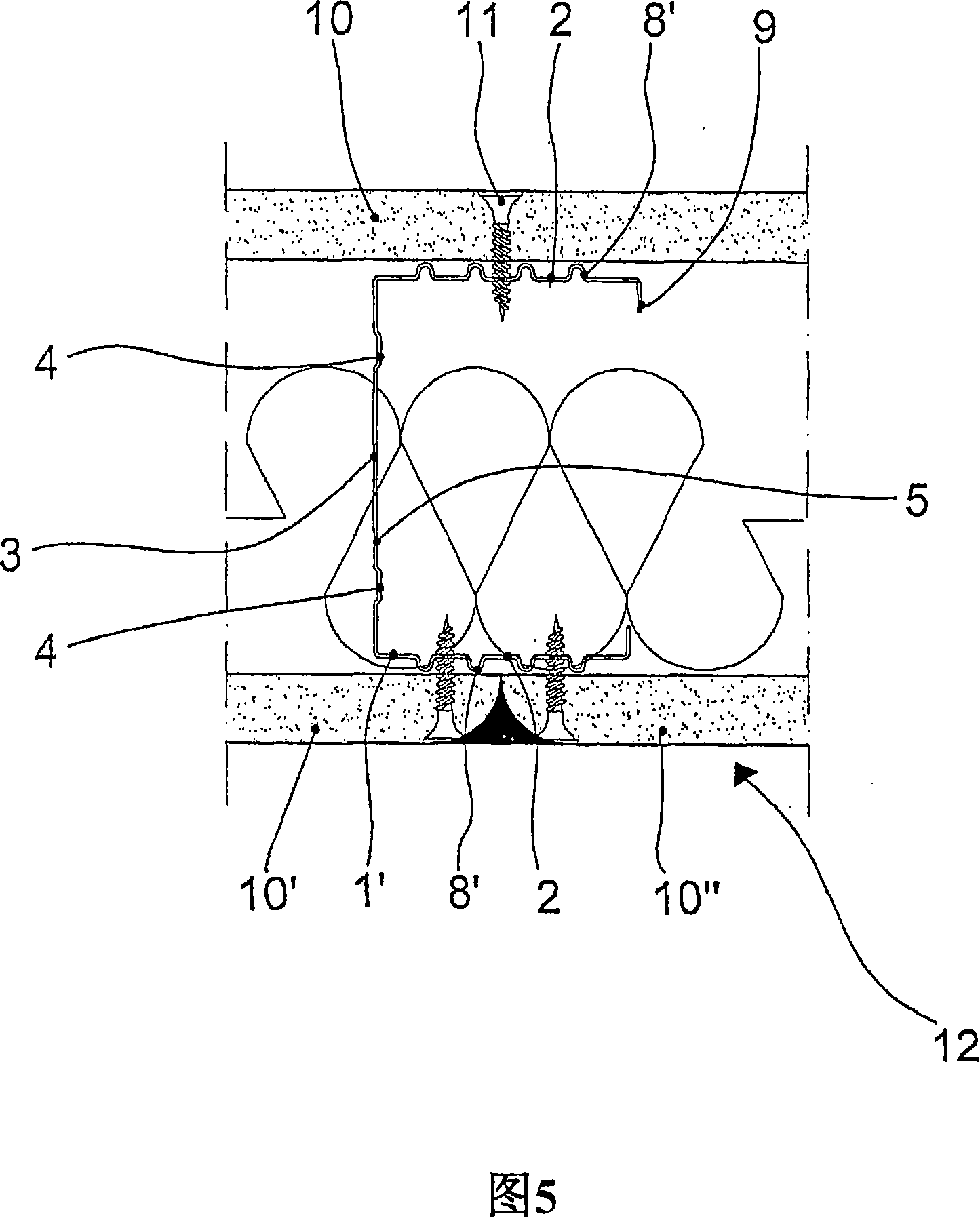

[0027] The figures show different embodiments of C-profiles 1 , 1 ′, 1 ″ made of sheet metal for partition walls covered on both sides. Each C-profile 1 , 1 ′, 1 ″ has two Sides 2 and a bottom 3 .

[0028] The base 3 is formed substantially flat. In the embodiment shown in FIGS. 1 to 3 , grooves 4 are provided on both sides in the outer region of the base 3 , which extend in the longitudinal direction of the C-profile 1 , 1 ′, 1 ″. The base 3 There may be openings, recesses or perforations not shown. The C-profiles 1 , 1 ′, 1 ″ here have an elongated shape. This also applies to bottom 3. Furthermore, the bottom 3 can also have a different form than that shown.

[0029] A side part 2 is arranged on each longitudinal side of the base 3 . As can be seen especially in FIG. 4 , the side 2 forms an opening angle R of greater than 90° with the bottom 3 in the unloaded state of the C-profile 1 , 1 ′, 1 ″. On the side facing the bottom 3 The opening angle R measured between the in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com