Descaling device for steam generator

A steam generator and scaling technology, applied in steam generation, components of steam boilers, steam boilers, etc., can solve problems such as expanding the cleaning range and difficult to clean nozzles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

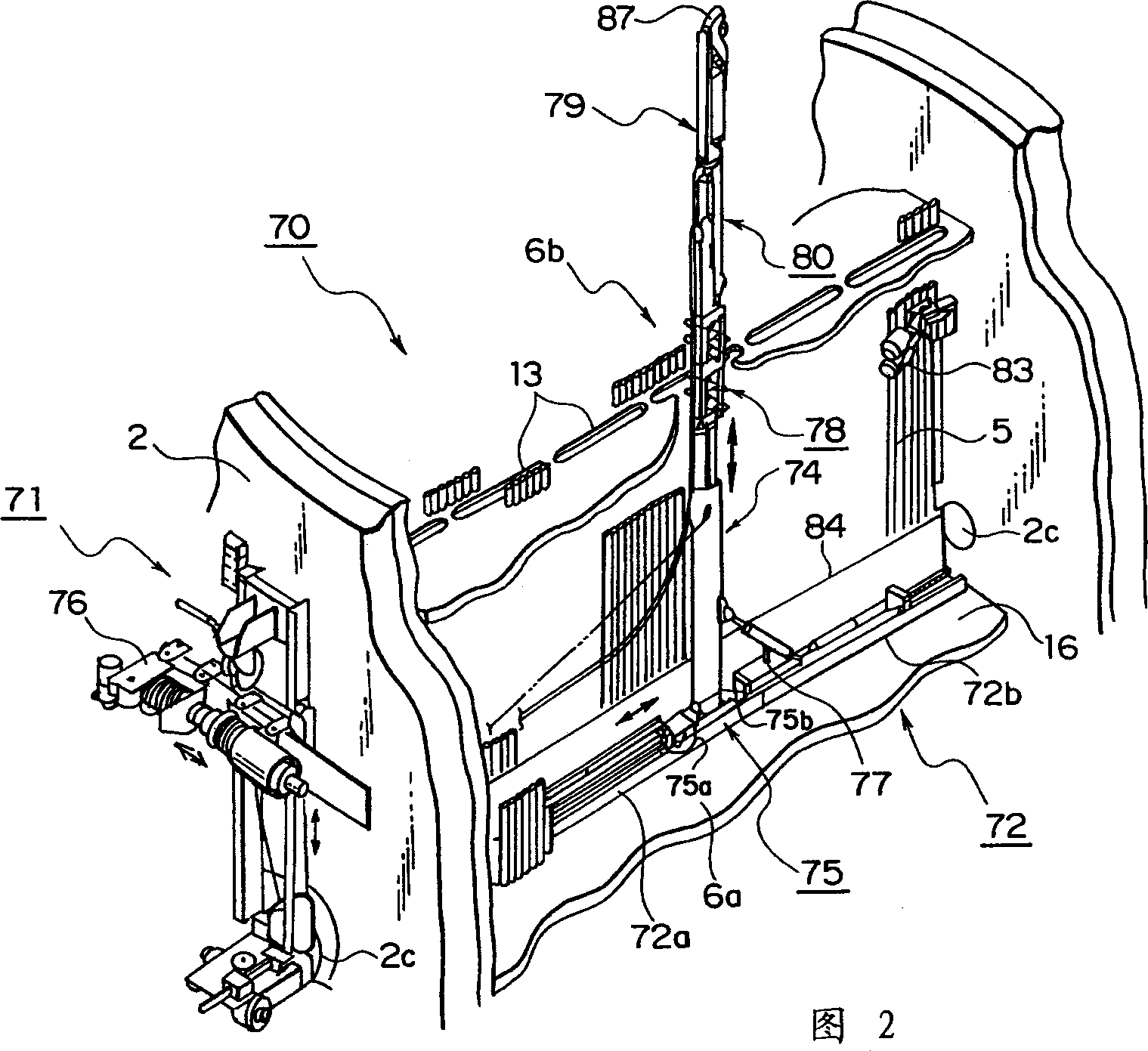

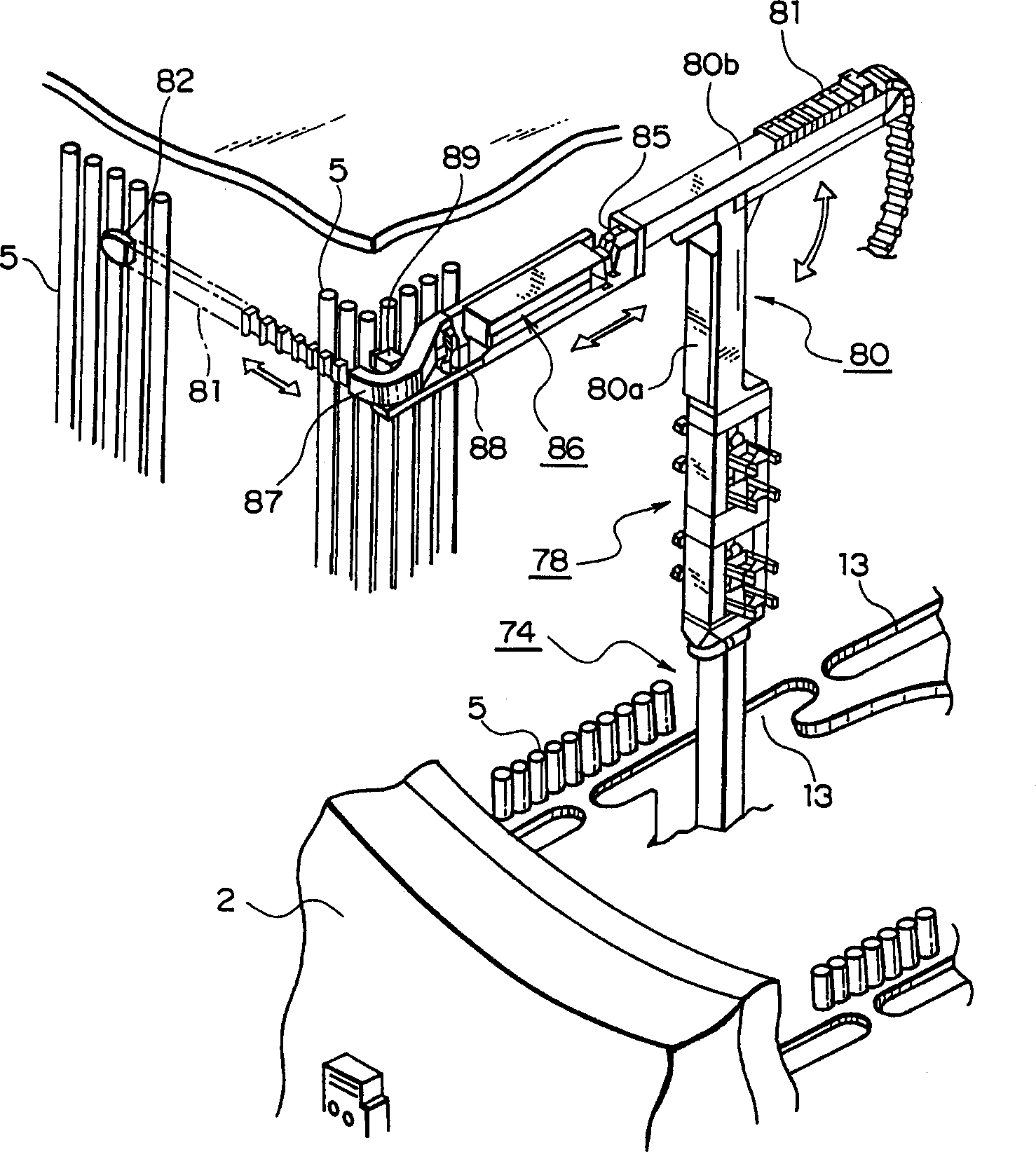

[0045] Hereinafter, preferred embodiments of the present invention will be described with reference to the accompanying drawings. In the drawings, elements that are the same as or corresponding to those in the above examples are identified by the same reference numerals. In addition, as can be seen from the following description, the present invention is not limited to this embodiment, but various improvements are possible.

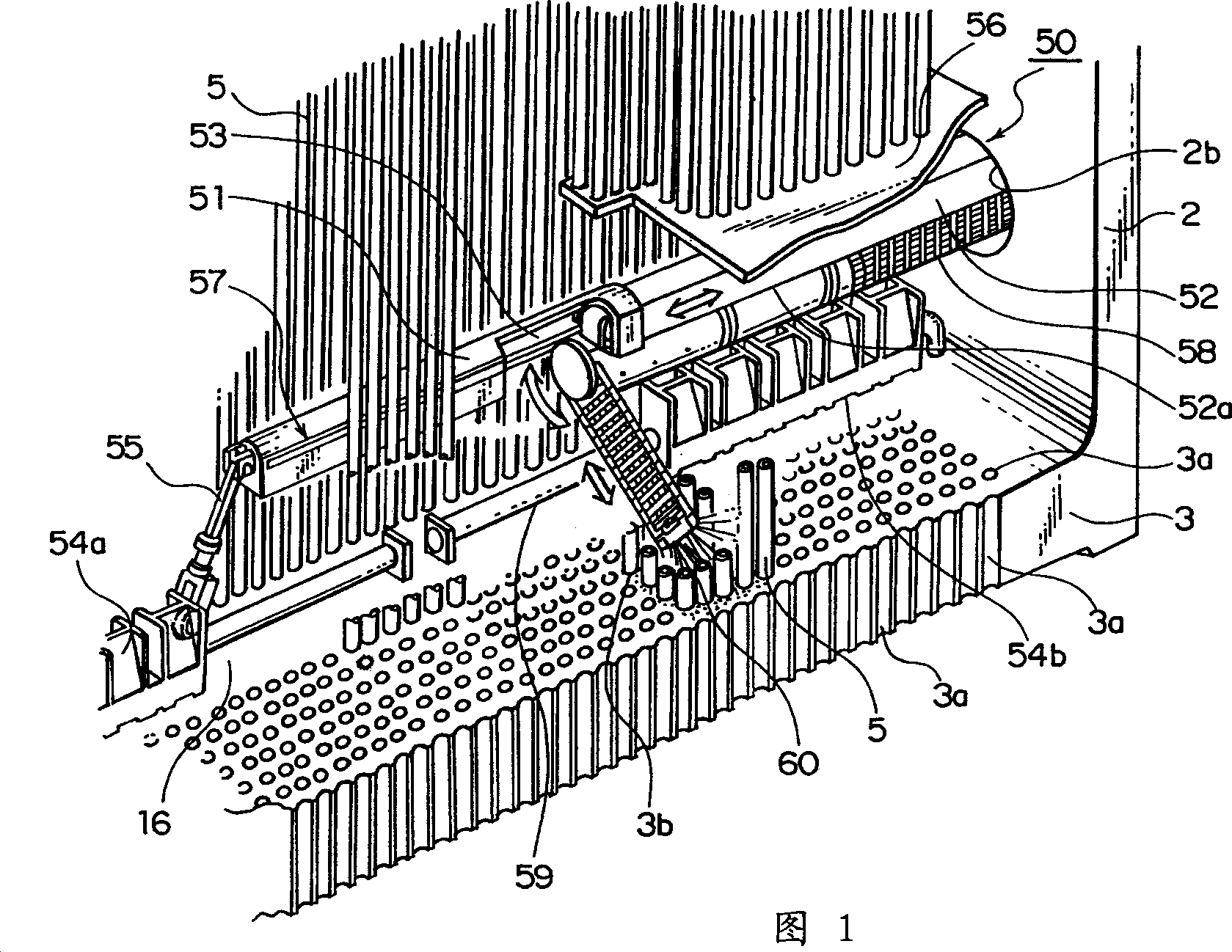

[0046] In FIG. 1, the main body part 2 shown is a scale removal device 50 for cleaning the part centered on the tube sheet according to the present invention. The tube sheet 3 has a large number of holes 3a, and the ends of the heat conducting tubes 5 are inserted into the holes and fixed in the holes in a water-tight manner. In addition, in the main body part 2, a pair of diametrically opposed circular exploration holes or observation holes 2b (only one of them is shown) is formed relatively close to the upper surface of the tube sheet 3, and the scale remov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com