Anti-fake paper board iwth layer dyed area and its making process

A local area and manufacturing method technology, applied in papermaking, textiles and papermaking, fiber raw material processing, etc., can solve the problems of increasing the difficulty of counterfeiting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

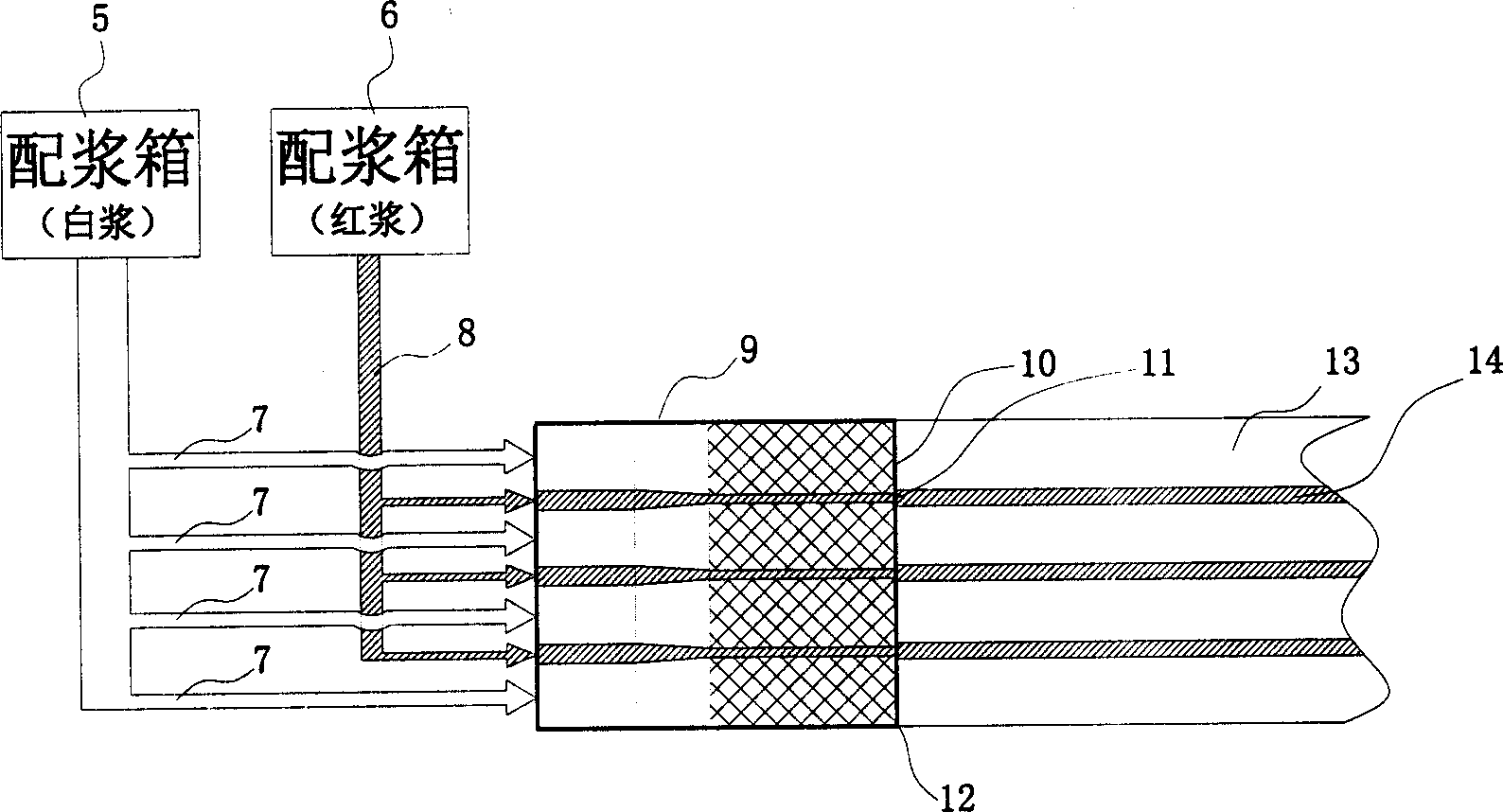

[0021] Example 1, see figure 1 , a process flow chart of a method for manufacturing anti-counterfeit cardboard: two independent pulp distribution boxes (5, 6) send pulp into the headbox (9) with their own independent pulp delivery channels (7, 8) respectively, and the pulp distribution box (5) is white pulp, and in the pulp box (6) is red pulp. At the nozzle position (12) of the headbox (9), the pulp box (5) sends the pulp through an independent pulp delivery channel (7). After entering the headbox, it is distributed at the nozzle (10) of the headbox (9) and sprayed out. The pulp distribution box (6) sends the pulp into the headbox through an independent pulp delivery channel (8) and then distributes it in the headbox. The position of the spout (11) of the box (9) is sprayed out, and after the pulp layer is formed on the net table, the pulp fibers in the band-shaped area (14) and the pulp fibers in the band-shaped area (13) are interwoven at the joint Afterwards, the pulp lay...

Embodiment 2

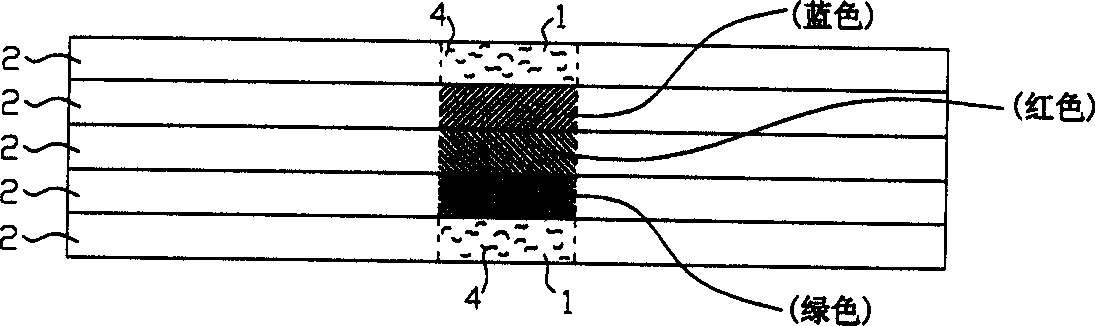

[0022] Example 2, see figure 2 , the anti-counterfeit cardboard is composed of five pulp layers, the upper surface pulp layer and the lower surface pulp layer band-shaped three-dimensional space (1) are embedded with colored fibers (4), the color characteristics of the pulp remain unchanged, all are white; the middle three pulp layers The strip-shaped three-dimensional space (1) overlaps up and down correspondingly, and the color characteristics of the pulp in each layer of strip-shaped three-dimensional space (1) are different, which are blue, red and green respectively, and the rest of the strip-shaped three-dimensional space (1) The color characteristics of the pulp in the part (2) are all white, or all gray, or all black, or all other same color characteristics.

[0023] Analyzing the anti-counterfeiting cardboard described in Example 2, there is a band-shaped three-dimensional space in each layer of pulp layer, so each headbox in the corresponding multi-wire paper machin...

Embodiment 3

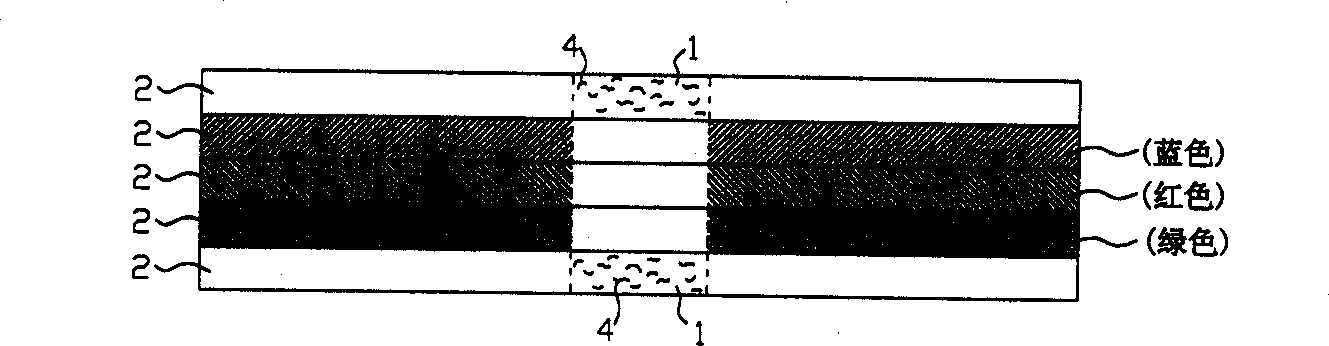

[0024] Example 3, see image 3 . The anti-counterfeit cardboard is composed of five pulp layers; the pulp in the strip-shaped three-dimensional space (1) of each pulp layer is white and overlaps up and down correspondingly, and the strip-shaped three-dimensional space (1) of the upper surface pulp layer and the lower surface pulp layer is embedded in the three-dimensional space (1). The colored fiber (4) has a pulp color characteristic of white; the color characteristics of each pulp layer in the remaining part (2) outside the band-shaped three-dimensional space (1) of the middle three pulp layers are blue, red and green respectively.

[0025] Analyzing the anti-counterfeit cardboard described in Example 3, there is a strip-shaped three-dimensional space in each layer of pulp layer, so each headbox in the corresponding multi-wire paper machine must be specially modified, so it is very difficult to imitate; In addition, only the paper pulp in the small strip-shaped three-dimen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com