Beam splitter and beam combiner with isolated polarized beam

A beam splitter and beam combiner technology, applied in the coupling of optical waveguides, instruments, optics, etc., can solve problems such as poor optical coupling, and achieve the effect of less loss and small volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

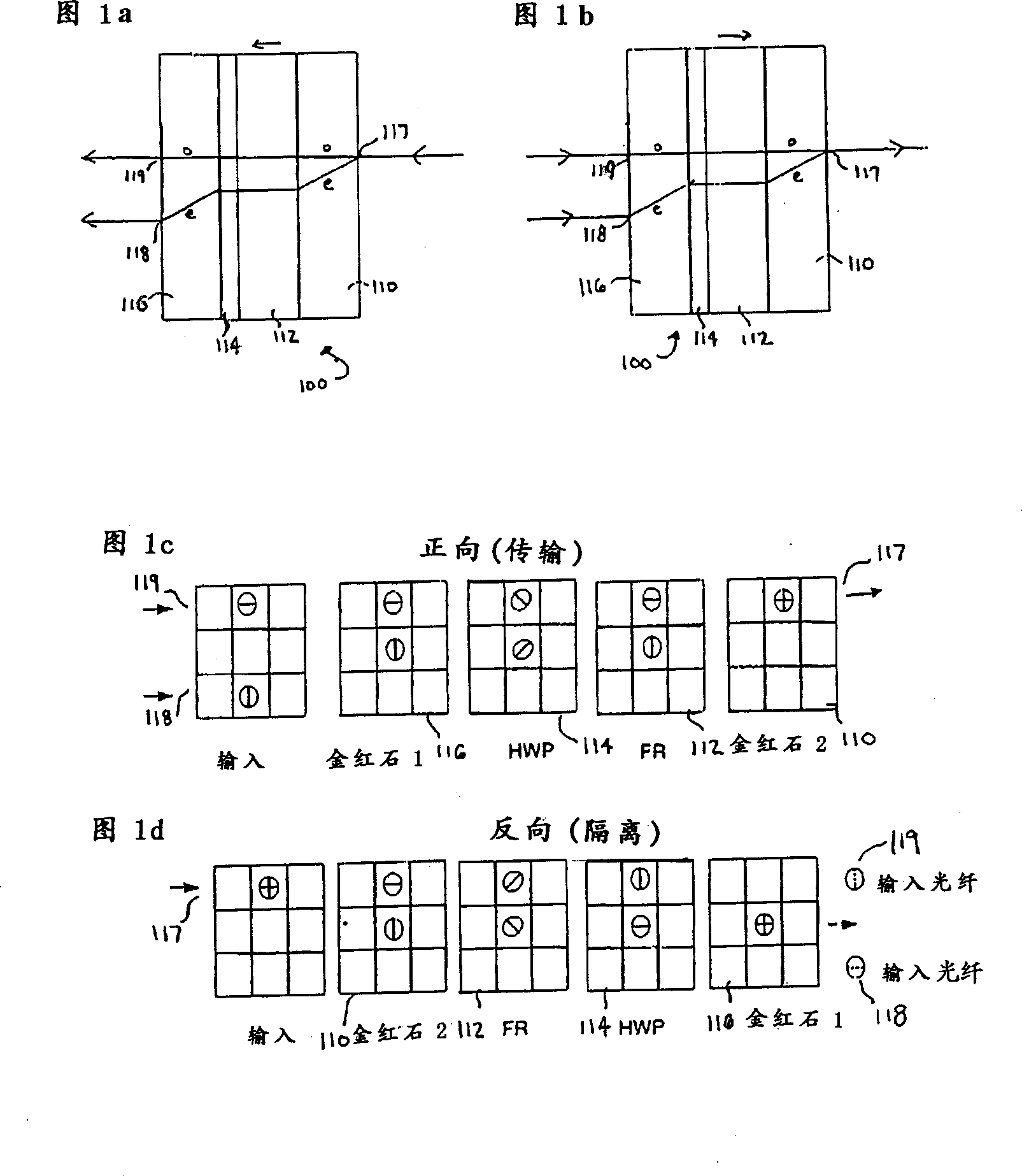

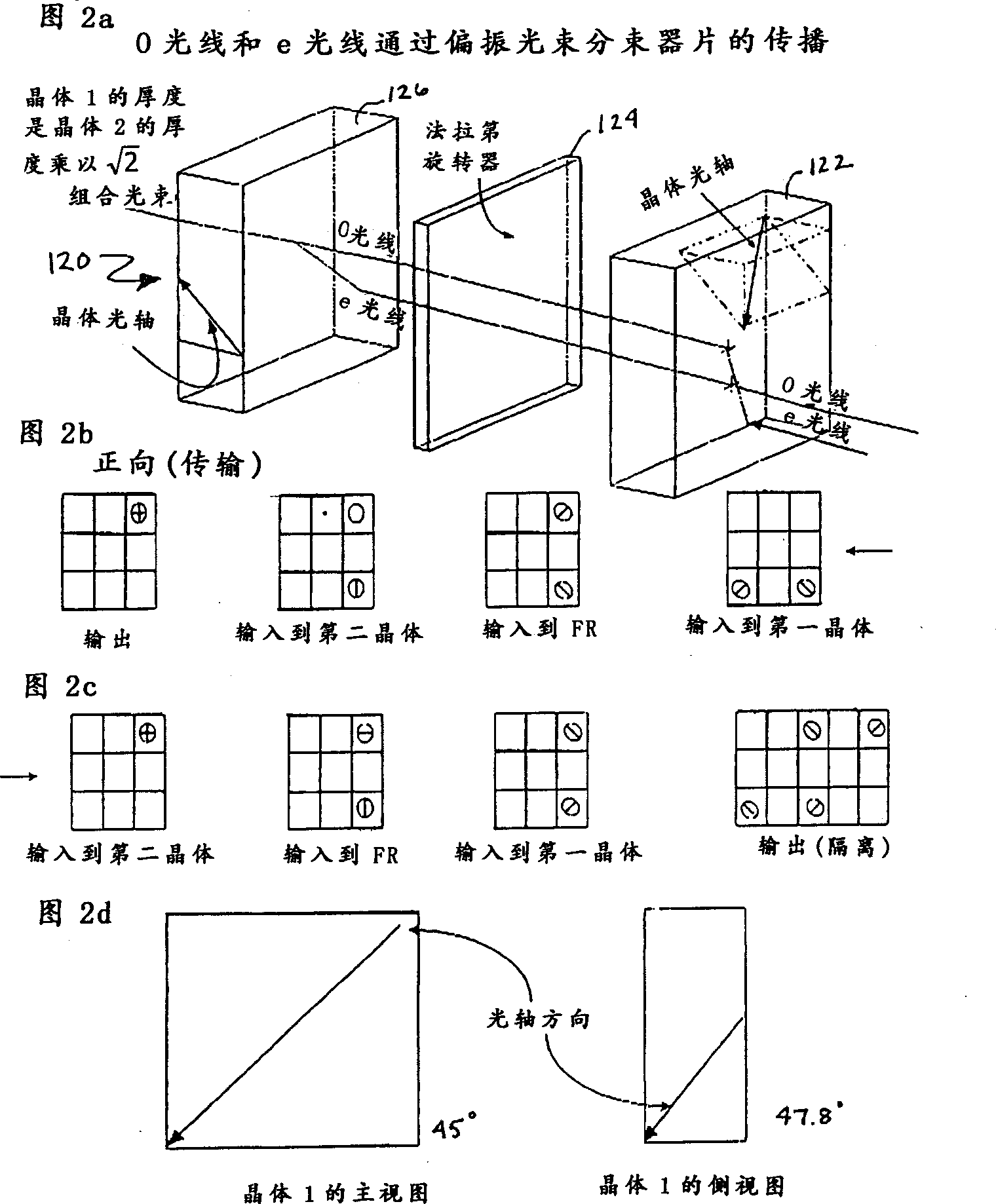

Method used

Image

Examples

Embodiment 200

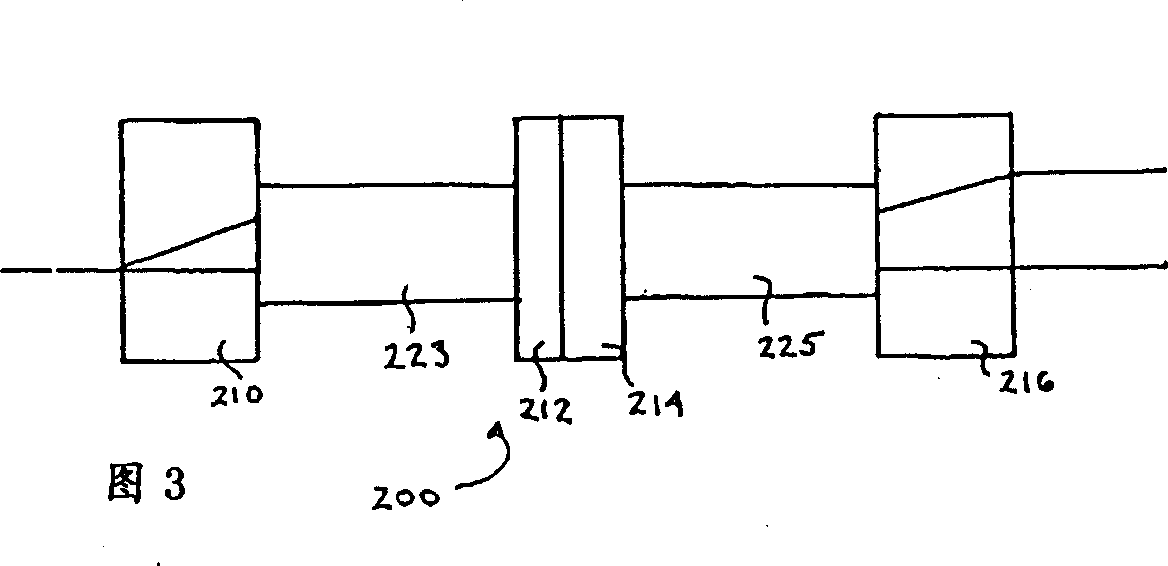

[0033] Fig. 3 is the further embodiment 200 of the present invention, and it comprises lens 223,225, is used for accepting the sub-beam from first crystal 210 and collimating the sub-beam directed to irreversible rotator 212,214, and when light passes through second Crystal 216 previously refocuses the sub-beams. Since the light from the crystal diverges and is no longer a point source, less than a quarter height span ratio gradient index (GRIN) lens can be used. Of course, other aspheric lenses can also be used. Advantageously, since the amplification ratio is 1:1, the coupling can be improved.

[0034] Figure 4a shows another embodiment of a polarizing beam splitter 250 with isolation. The first crystal 252 splits the orthogonally polarized light into sub-beams. Single crystal 252 is sized to provide effective beam spacing. The sub-beams pass through a half-wave plate 254 with an optical axis of 22.5° and a Faraday rotator 256, which together rotate the sub-beams 90° in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com