Single sheet paper transferring roller

A transfer roller, sheet-fed technology, used in the direction of shipping and packaging, printing, printing presses, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

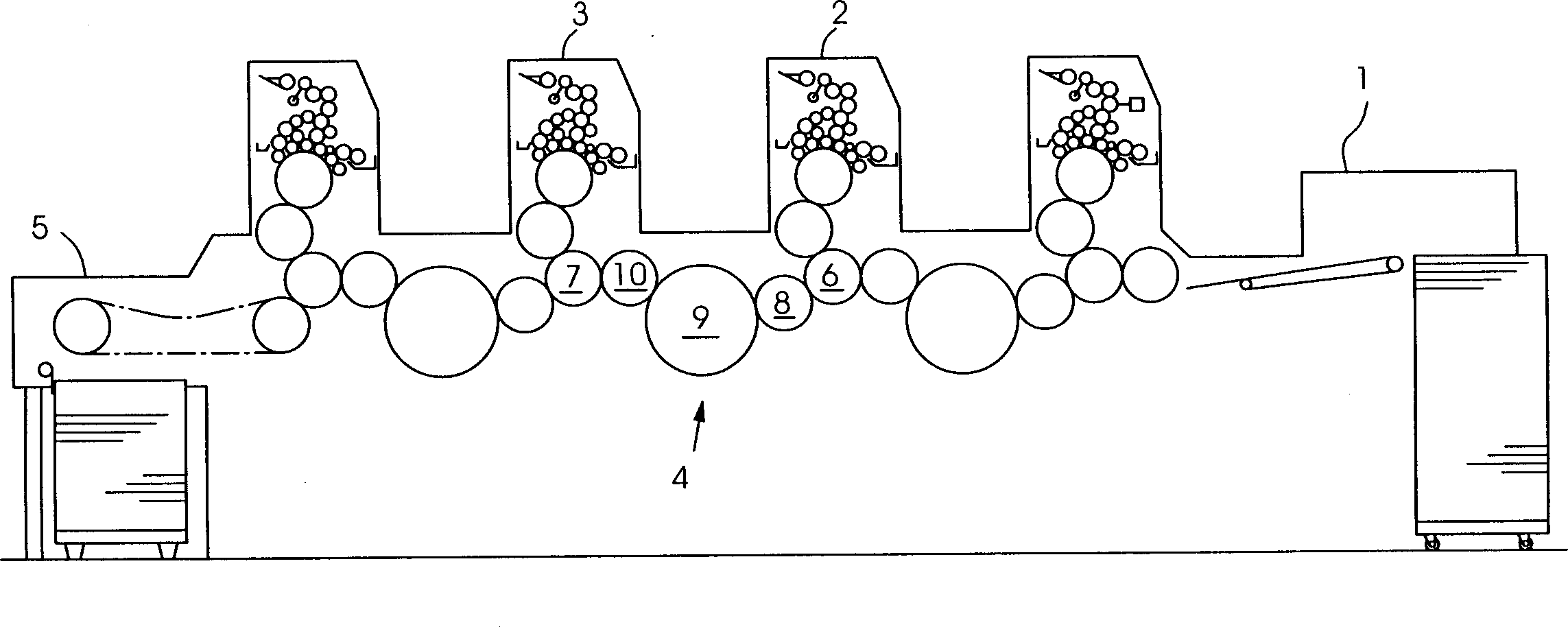

[0012] exist figure 1 shows a tandem sheet-fed rotary printing press with a sheet feeder 1, with printing units 2, 3 for printing sheet-fed substrates according to the offset printing method, with a printing unit 2, 3 3 between an overturning device 4 and a sheet-fed delivery device 5 .

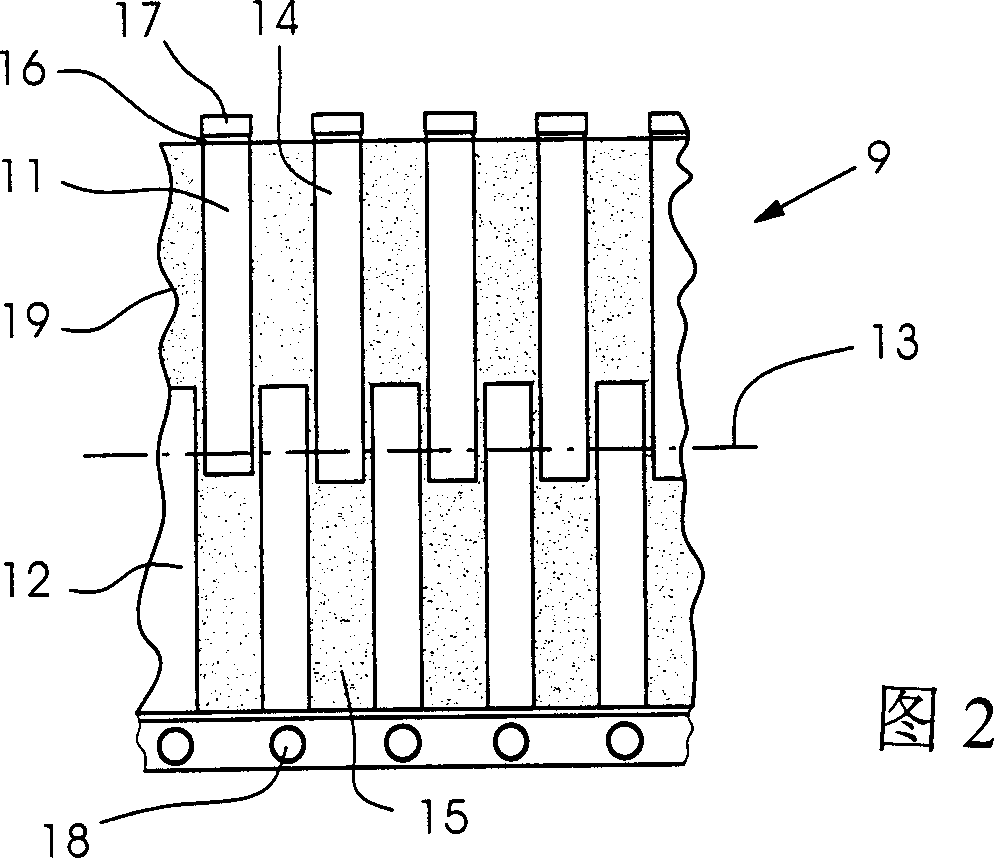

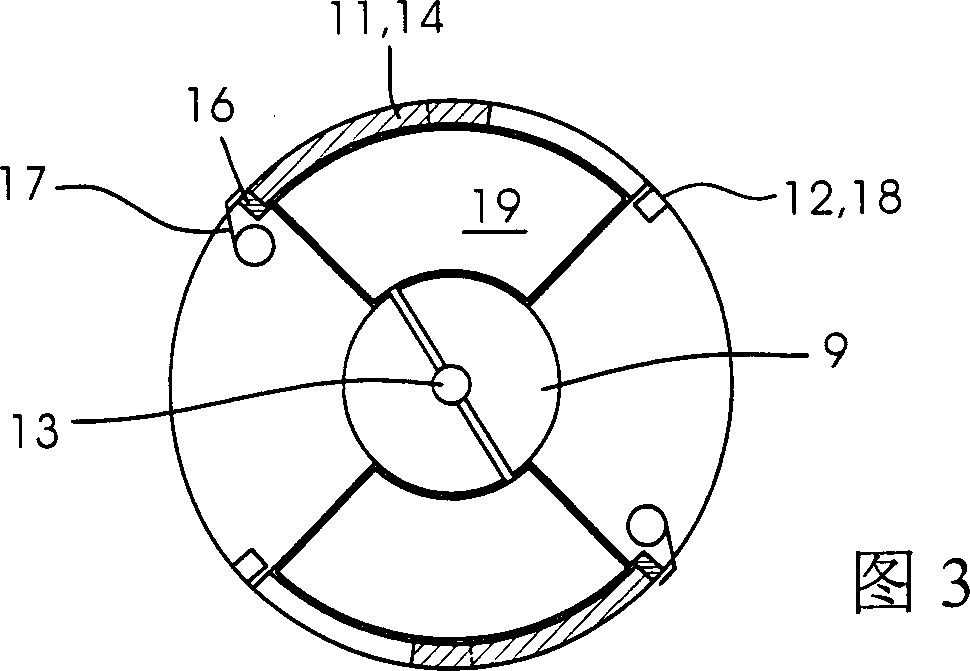

[0013] Each printing unit 2 , 3 comprises an impression cylinder, a blanket cylinder and an opposing impression cylinder 6 , 7 . The turning device 4 has three sheet-sheet transport cylinders 8 , 9 , 10 arranged between opposing impression cylinders 6 , 7 . The sheet-fed transfer cylinder 9 acts as a so-called storage cylinder and holds the sheet-fed printing material firmly on its leading edge by means of its gripper system. The sheet-fed transfer cylinder 10 acts as a so-called reversing cylinder (Wendetrommel) and by means of its gripper system grabs a rear edge of the sheet-fed substrate in order to turn it over and remove it from the sheet-fed transfer drum. 9 up and down.

[0014] A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com