Constant force spring support hanger frame whose supporting and hanging forces and displacement do not change and loading force can be regulated

A technology with constant direction and constant force springs, applied in the directions of pipeline supports, instrument parts, instruments, etc., it can solve the problems that the bearing force cannot be kept constant, the stable work is unfavorable, and the adaptability is not strong, and the implementability is achieved. Strong, automatic balance medium reaction force, cleverly conceived effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

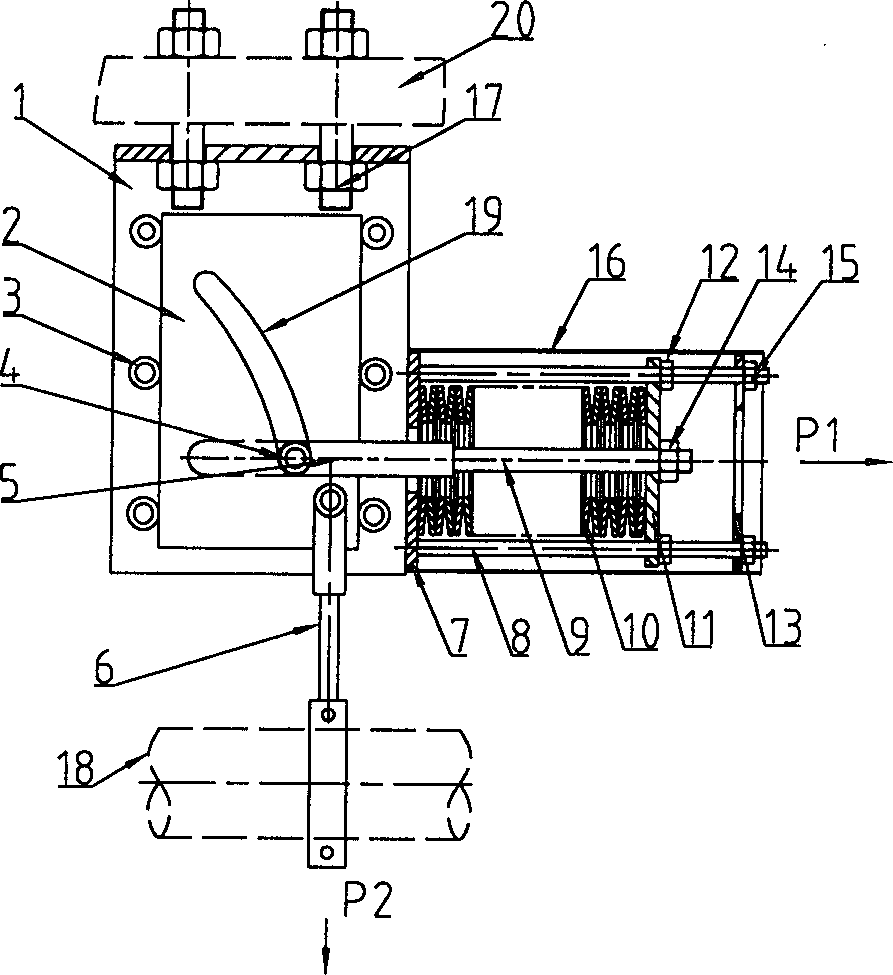

[0027] This example figure 1 As shown, it is mainly composed of a fixed frame (1), a rectangular displacement plate (2), a guide wheel (3), a roller (4), a disc spring pull plate (5), a boom (6), a front pressure plate (7), and a guide Rod (8), disc spring pull rod (9), disc spring group (10), rear pressure plate (11), pre-compression nut (12), fixed plate (13), compression nut (14), fixed nut ( 15), shell (16), fixed rooting bolt (17), displacement groove (19) and other components.

[0028] In this embodiment, the disc spring group (10) corresponds to the spring energy storage part in the technical solution, the disc spring pull plate (5) corresponds to the load coupling part, and the suspender (5) corresponds to the load transmission part. 6). The disc spring group (10) is clamped by the front and rear pressure plates (7, 11) and the pre-compression nut (12) on the guide rod (8) is locked according to the preloaded height of the disc spring group (10), Be fixed on one sid...

Embodiment 2

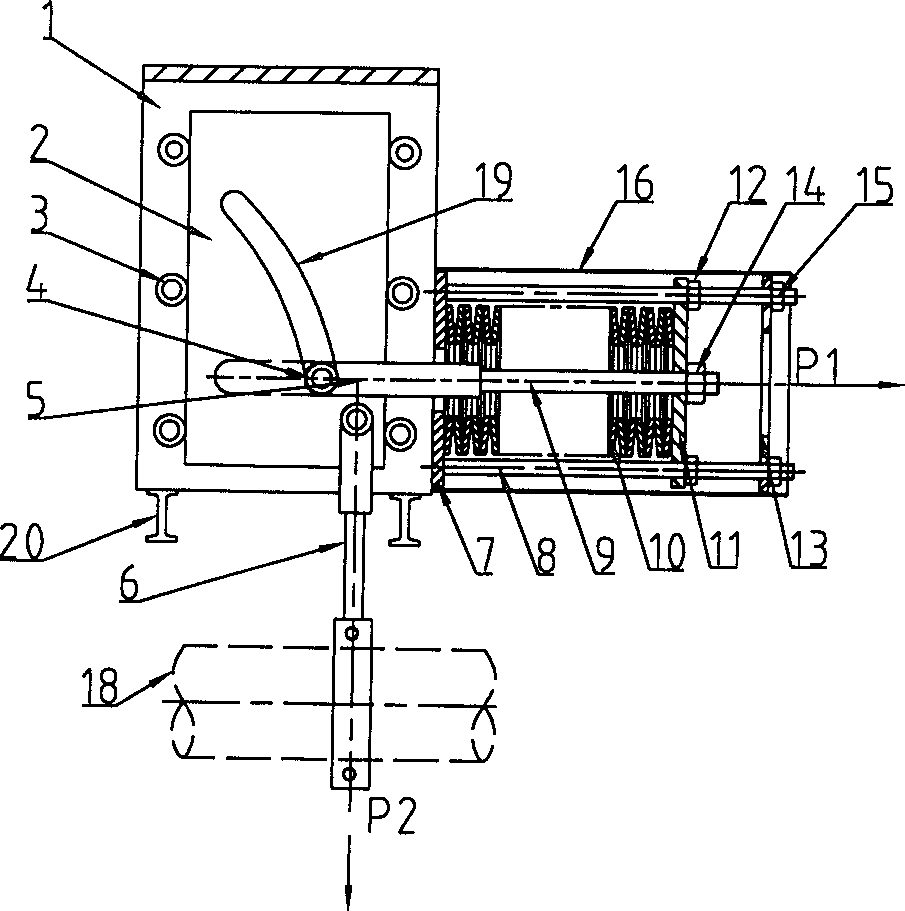

[0036]This example figure 2 As shown, it can be called a flat constant force disc spring seat hanger, and its structure and working principle are basically the same as those in Embodiment 1. The difference is that during installation, the lower end of the fixed frame (1) is supported on the I-beam (20).

Embodiment 3

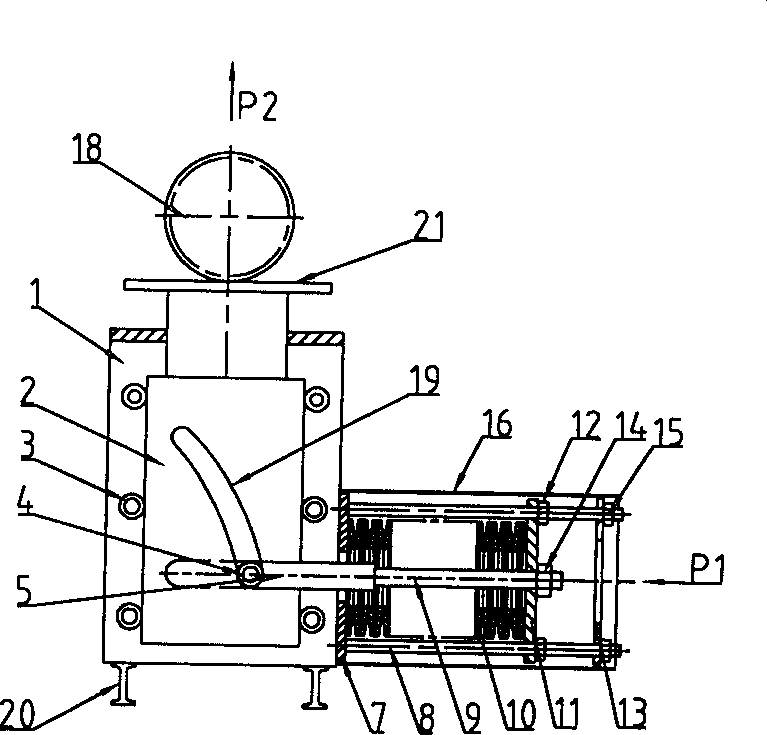

[0038] This embodiment is a flat constant force disc spring support, and its structure is as follows image 3 Shown, also basically the same as embodiment one, fixed frame (1) and figure 2 Similarly, the lower end of the fixed frame (1) is supported on the I-beam (20). The difference is that the load transmission part is not a suspension rod, but a support plate (21), and the pipeline or other load equipment (18) is supported above the support plate (21).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com