Device for the separation of substrates from a stack

A technology for equipment and substrates, which is used in pile separation, stone processing equipment, object separation, etc., can solve the problems of time required for separation and damage to the edge of related silicon wafers, and achieve the effect of avoiding damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

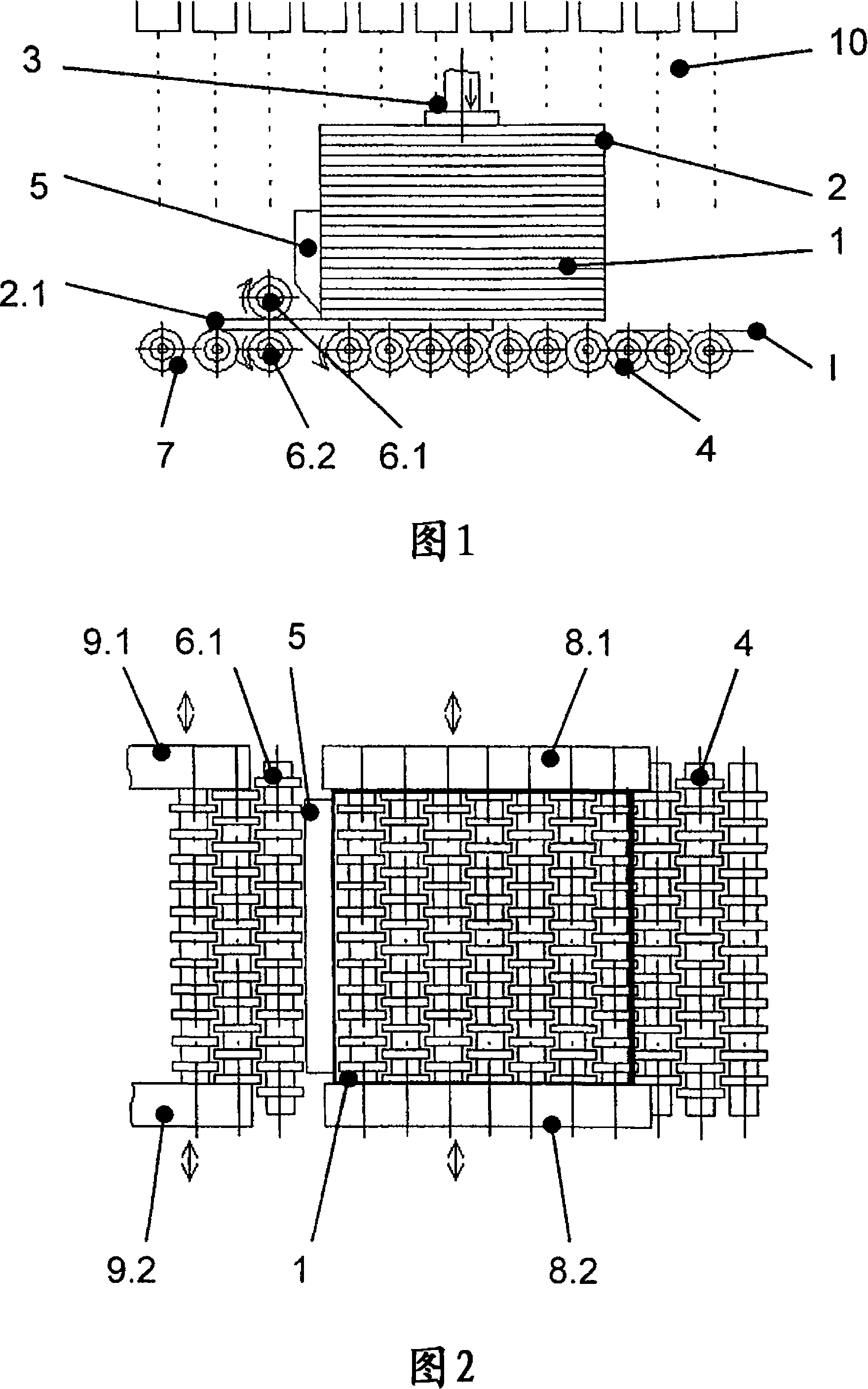

[0014] In FIG. 1 a wafer stack 1 of silicon wafers 2 can be seen, which is formed by cutting a silicon block by means of a wire saw into a plurality of silicon wafers 2 , wherein the silicon blocks are joined by gluing It is bonded to the carrier glass pane and the silicon wafer 2 is detached or detached from the bottom of the carrier glass pane on the connection or adhesive layer after wire sawing. A stack 1 of wet silicon wafers 2 stacked in layers is placed on a separating roller 4 which rotates continuously during destacking. The wafers 2 are constantly kept moist by means of a watering device 10 to facilitate depalletizing and subsequent handling. A pressure head (Stempel) 3 with adjustable contact force keeps the bearing force of the separation roller constant independently of the height of the wafer stack, wherein the separation roller is elastic and thus flexible on the outer peripheral side. This achieves that the gap between the separating roller plane 1 and the scr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com