Cold-warm air conditioner

An air conditioner, cooling and heating technology, which is applied in the direction of refrigerators, refrigeration components, refrigeration and liquefaction, etc., can solve the problems of unfavorable air conditioner throttling conditions and inability to throttling twice, achieve novel structure, improve efficiency, and reduce energy consumption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

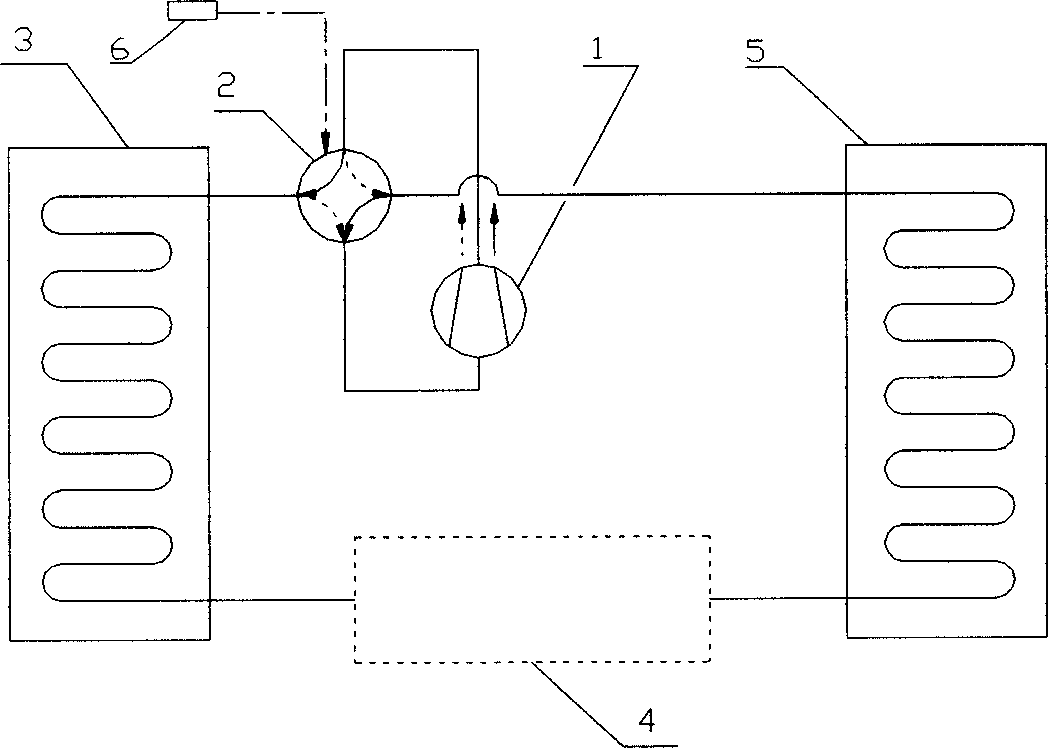

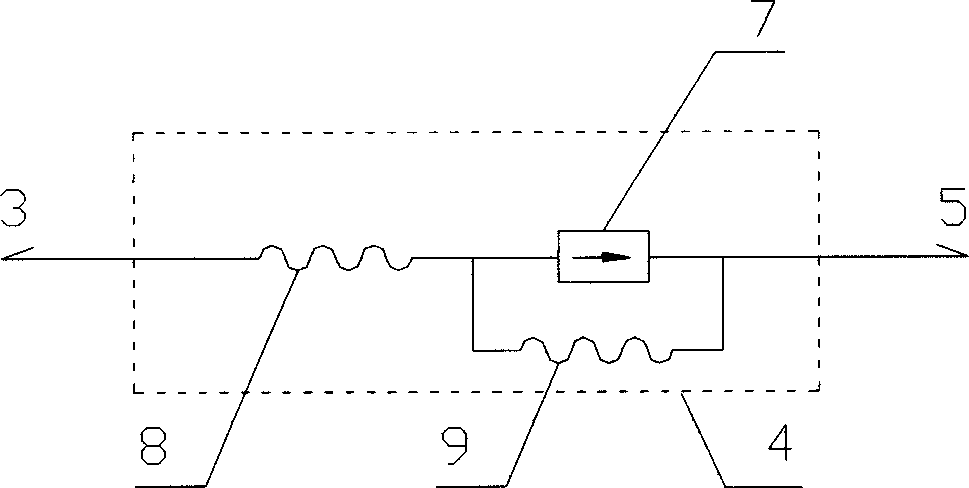

[0039] Embodiment 1 is provided with the circulation system of the heating and cooling air conditioner of specific throttling device, as attached figure 1 And attached figure 2 . Compressor 1, four-way reversing valve 2, outdoor heat exchanger 3, throttling device 4, indoor heat exchanger 5, heating and cooling switch 6, one-way valve 7, capillary 8, capillary 9, connecting pipeline and auxiliary equipment A cooling or heating cycle. When the heating and cooling switch 6 selects the cooling mode, the refrigerant flowing out of the compressor 1 flows through the four-way reversing valve 2 to the outdoor heat exchanger 3 to condense, and then flows through the capillary 8 and the one-way valve 7 to enter the indoor heat exchanger 5 , the refrigerant returns to the compressor 1 through the four-way reversing valve 2 after being evaporated and refrigerated in the indoor heat exchanger 5 . When the cooling and heating switch 6 selects the heating mode, the one-way valve 7 is no...

Embodiment approach 2

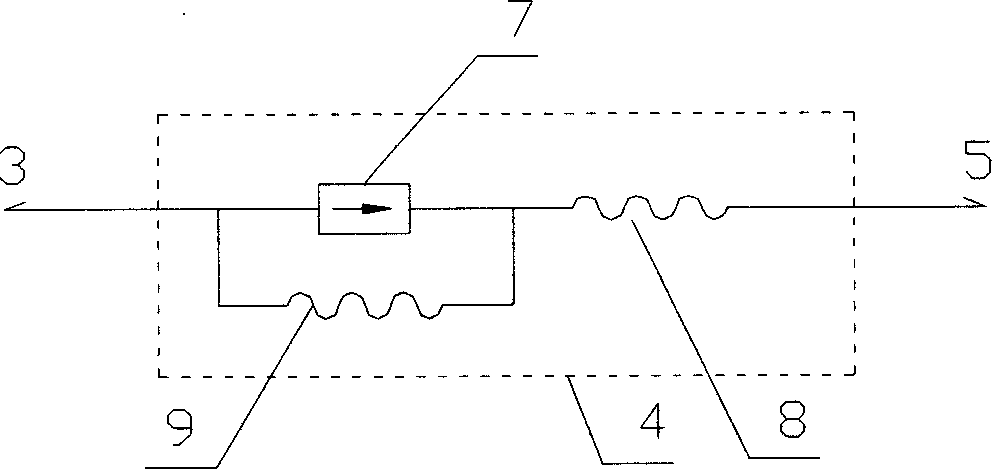

[0041] Embodiment 2 is provided with the circulation system of the heating and cooling air conditioner of specific throttling device, as attached figure 1 And attached image 3. Compressor 1, four-way reversing valve 2, outdoor heat exchanger 3, throttling device 4, indoor heat exchanger 5, heating and cooling switch 6, one-way valve 7, capillary 8, capillary 9, connecting pipeline and auxiliary equipment A cooling or heating cycle. When the heating and cooling switch 6 selects the cooling mode, the refrigerant flowing out of the compressor 1 flows to the outdoor heat exchanger 3 through the four-way reversing valve 2 to condense, and then flows through the one-way valve 7 and the capillary tube 8 to enter the indoor heat exchanger 5 , the refrigerant returns to the compressor 1 through the four-way reversing valve 2 after being evaporated and refrigerated in the indoor heat exchanger 5 . When the cooling and heating switch 6 selects the heating mode, the one-way valve 7 is...

Embodiment approach 3

[0043] Embodiment 3 is provided with the circulation system of the heating and cooling air conditioner of specific throttling device, as attached figure 1 And attached Figure 4 . Compressor 1, four-way reversing valve 2, outdoor heat exchanger 3, throttling device 4, indoor heat exchanger 5, heating and cooling switch 6, one-way valve 7, expansion valve 10, expansion valve 11, connecting pipeline and auxiliary The devices form a cooling or heating cycle. When the heating and cooling switch 6 selects the cooling mode, the refrigerant flowing out of the compressor 1 flows to the outdoor heat exchanger 3 through the four-way reversing valve 2 to condense, and then flows through the expansion valve 10 and the one-way valve 7 to enter the indoor heat exchanger 5. After the refrigerant evaporates and cools in the indoor heat exchanger 5, it returns to the compressor 1 through the four-way reversing valve 2. When the cooling and heating switch 6 selects the heating mode, the one-...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap