Ferroelectric liquid crystal display and manufacturing method thereof

A technology of ferroelectric liquid crystals and displays, applied in instruments, nonlinear optics, optics, etc., can solve problems such as dim display, afterimages, and residues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Hereinafter, a ferroelectric liquid crystal display and its manufacturing method will be described in more detail according to illustrative and non-limiting preferred embodiments of the present invention with reference to the accompanying drawings.

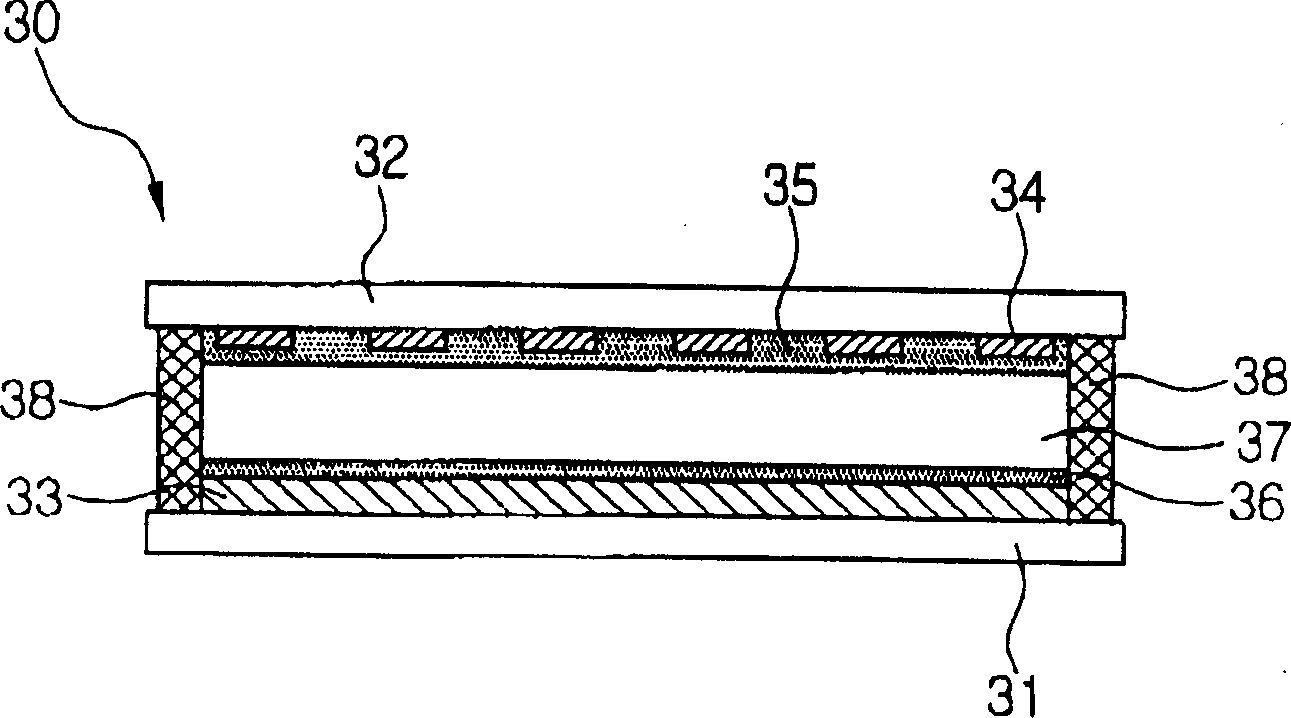

[0017] figure 2 is a sectional view showing a ferroelectric liquid crystal display according to the present invention.

[0018] refer to figure 2 , the ferroelectric liquid crystal display 30 comprises: a lower substrate 31, a lower electrode layer 33, a lower alignment layer 36, a liquid crystal layer 37, an upper alignment layer 35, an upper electrode layer 34, an upper substrate 32, and A package component 38 . On the non-facing outer sides of the lower substrate 31 and the upper substrate 32, polarizing plates (not shown) are arranged.

[0019] The upper and lower substrates 32 and 31 are made of a transparent material such as glass.

[0020] The upper and lower electrode layers 34 and 33 are made of transparent a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com