Buoy having waveforce self-generating unit and waveforce generating method

A technology of self-generated power and buoys, applied in marine signal devices, buoys, ocean energy power generation, etc., and can solve problems such as unusability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

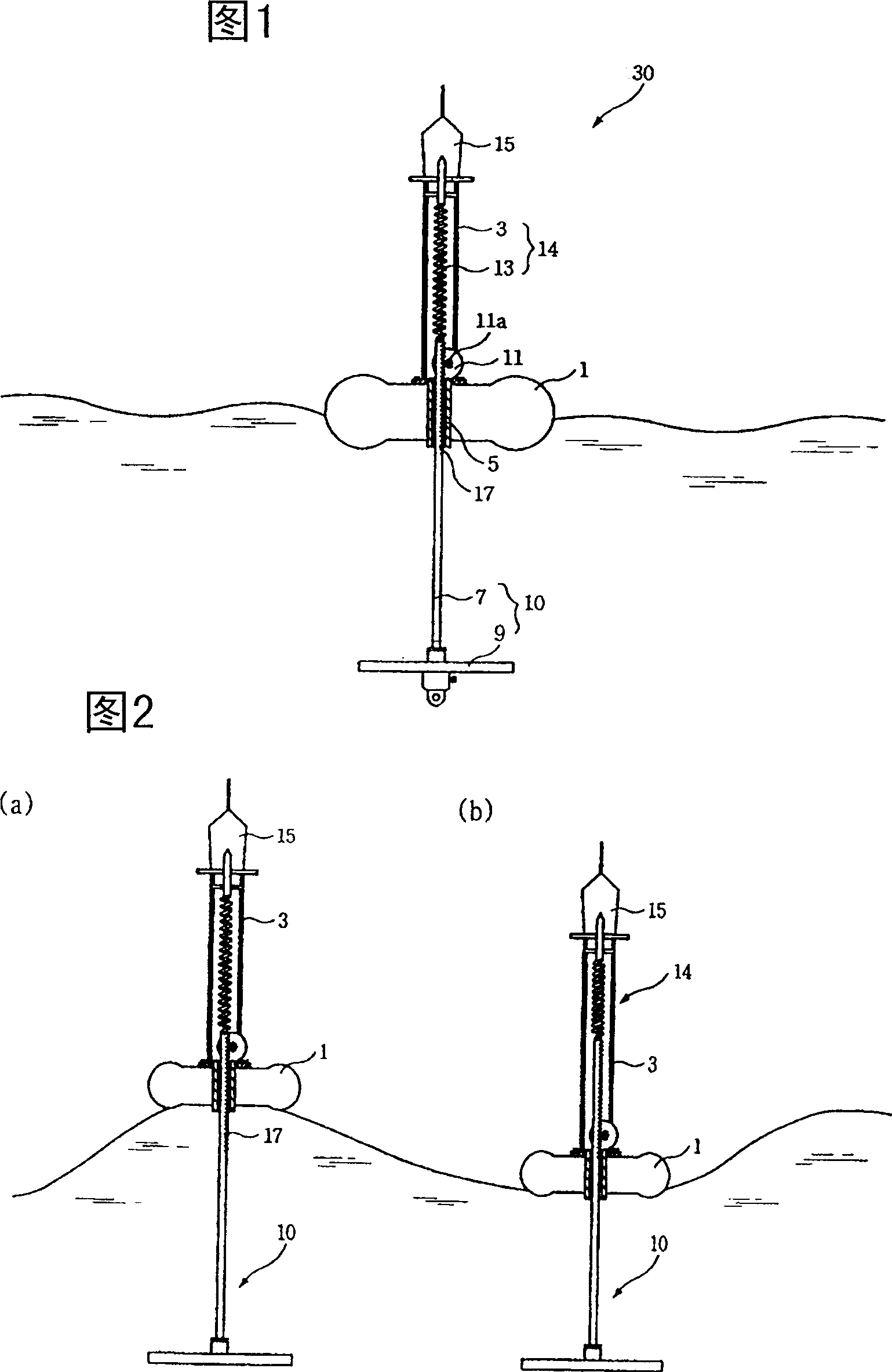

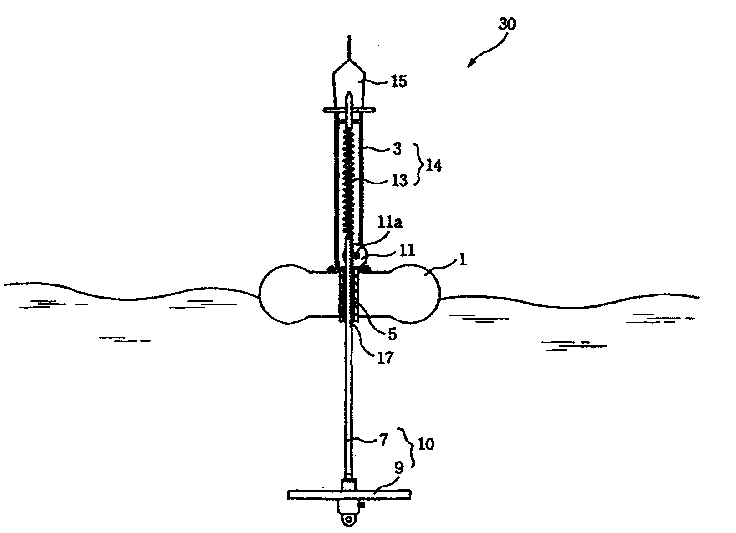

[0014] As shown in FIG. 1 , the self-generating buoy 30 using wave power according to the present invention is composed of a series of components, so that the kinetic energy of waves is converted into electrical energy through a generator.

[0015] The buoy includes: a floating body 1 , a lower feeding part 10 , a generator 11 , an upper support 14 and a navigation light 15 . The floating body 1 floats on the sea surface, and its center is provided with a vertical guide sleeve 5 .

[0016] The lower feeding part 10 is composed of a mandrel 7 and a resistance plate 9: the upper part of the mandrel 7 can move relative to the floating body 1 in the vertical direction in the guide sleeve 5; the resistance plate 9 is fixed on the lower end of the mandrel 7 and extends into the sea . When the floating body 1 moves up and down under the action of waves, the resistance plate 9 hinders the movement of the lower feeding part 10, so the two generate relative reciprocating motion along t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com