Reduction process of preparing nano cuprous oxide wire

A technology of cuprous oxide and reduction method, applied in the direction of copper oxide/copper hydroxide, etc., can solve the problem of no copper oxide nanowires, etc., and achieve the effect of easy operation and repetition, convenient industrial production, and simple experimental process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

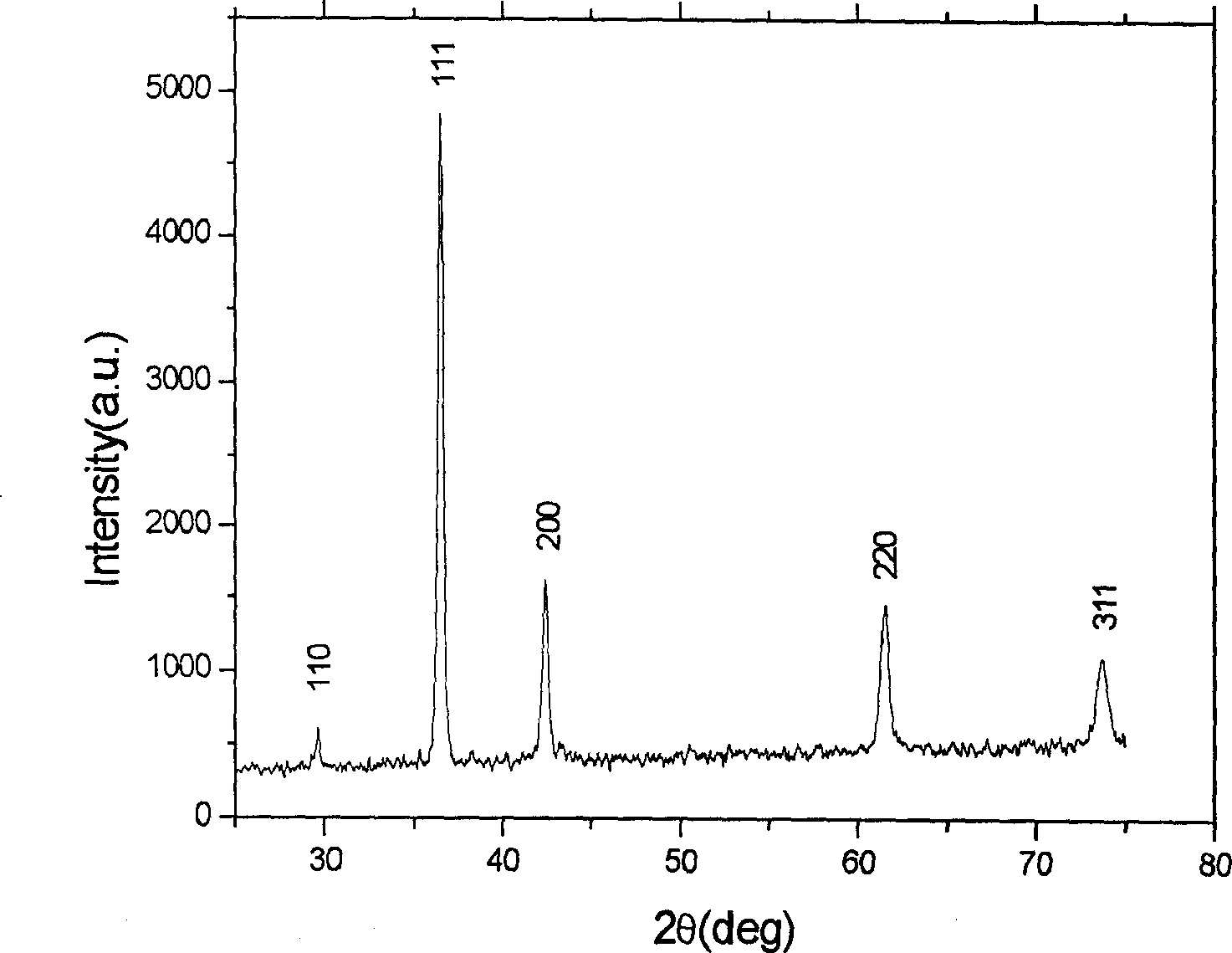

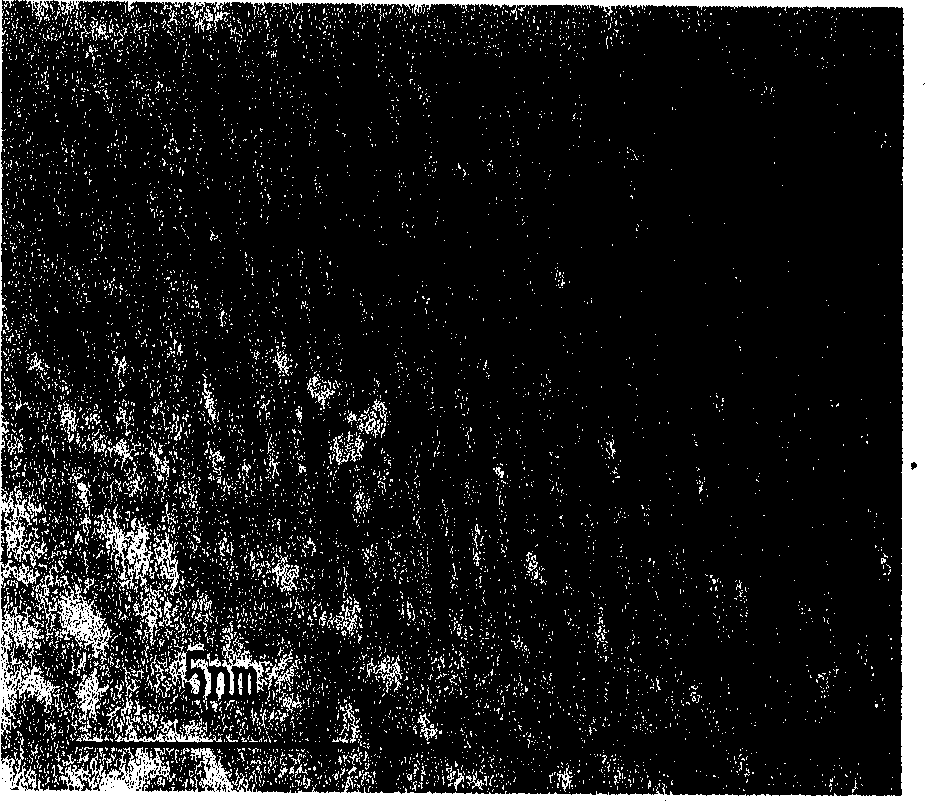

[0015] Example of the method for preparing cuprous oxide nanowires by the reduction method: dissolve 200 mg of polyethylene glycol and a certain amount of cupric chloride 178.5 mg in 200 ml of deionized water, stir with a magnetic stirrer for 10-15 minutes, and wait for the polyethylene glycol After diol dissolves completely, in this solution, dropwise the sodium hydroxide solution of 1.2ml under constant stirring rate, stir 15 minutes to ensure that reaction is thorough and all generate the blue copper hydride precipitation, then under constant stirring rate to 1.5 ml of hydrazine hydrate solution with a concentration of 13.7 mol / l was added dropwise to the blue copper hydroxide precipitation solution. After the blue copper hydroxide precipitate is completely reduced to the red cuprous oxide precipitate, wash the red cuprous oxide several times with deionized water, then filter it, and bake it in a vacuum oven at 55-65°C for 3 hours to remove it. moisture.

[0016] The embod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com