One unit print using multiple picture elements as hus reproducing

A pixel position and pixel technology, applied in the field of printing technology, can solve the problems of limited local tone reproducibility and low degree of freedom of local tone reproducibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

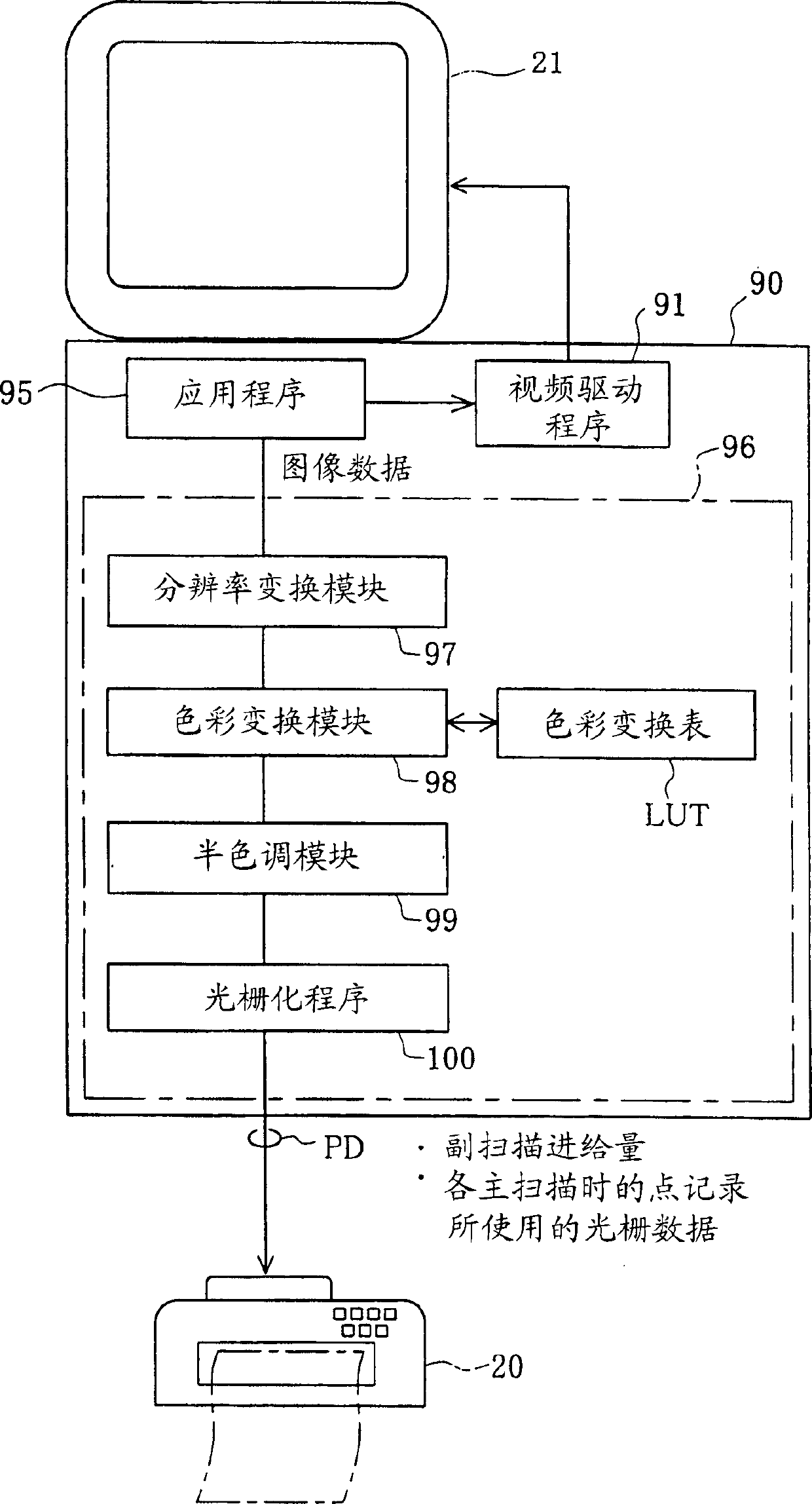

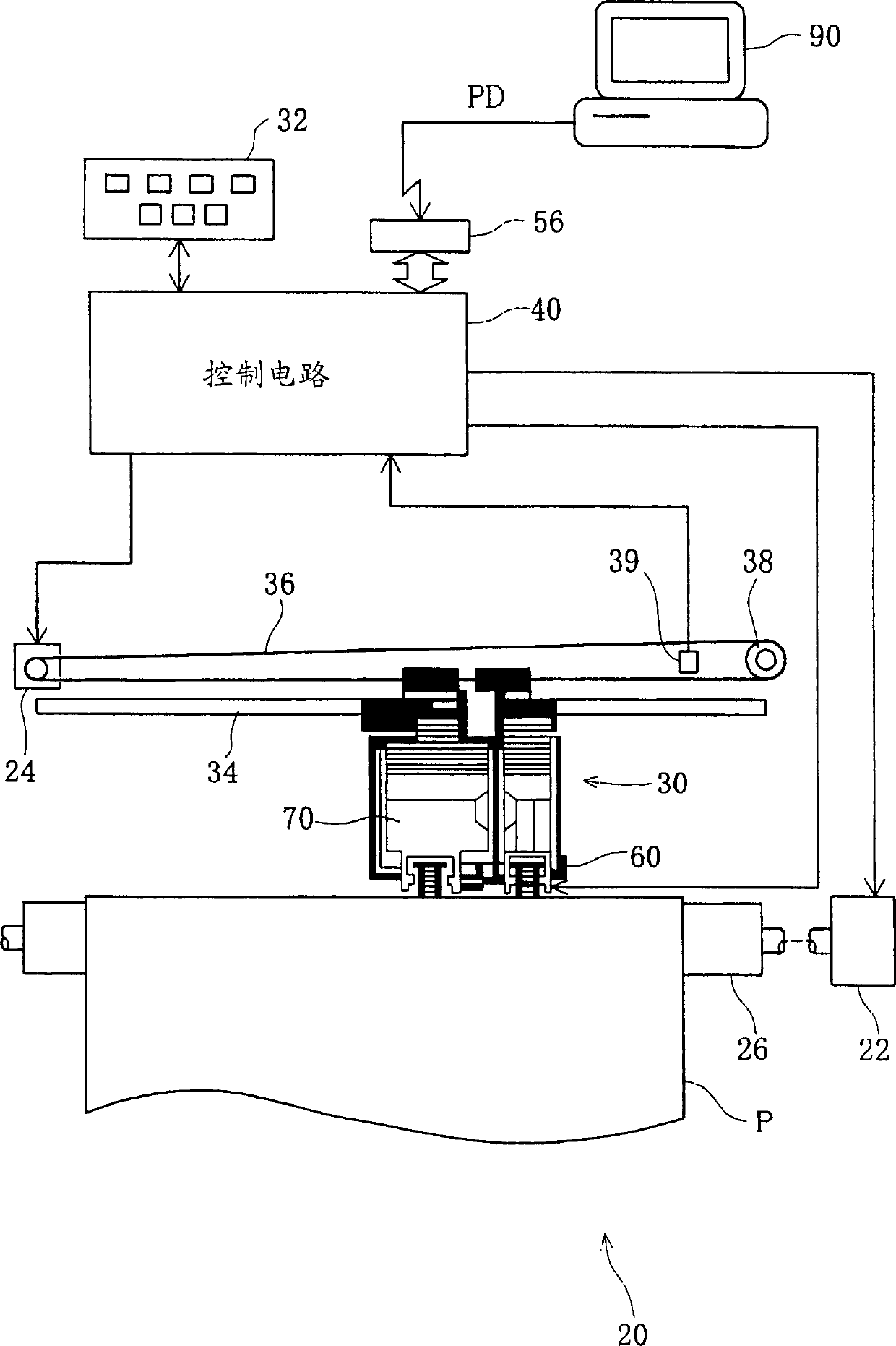

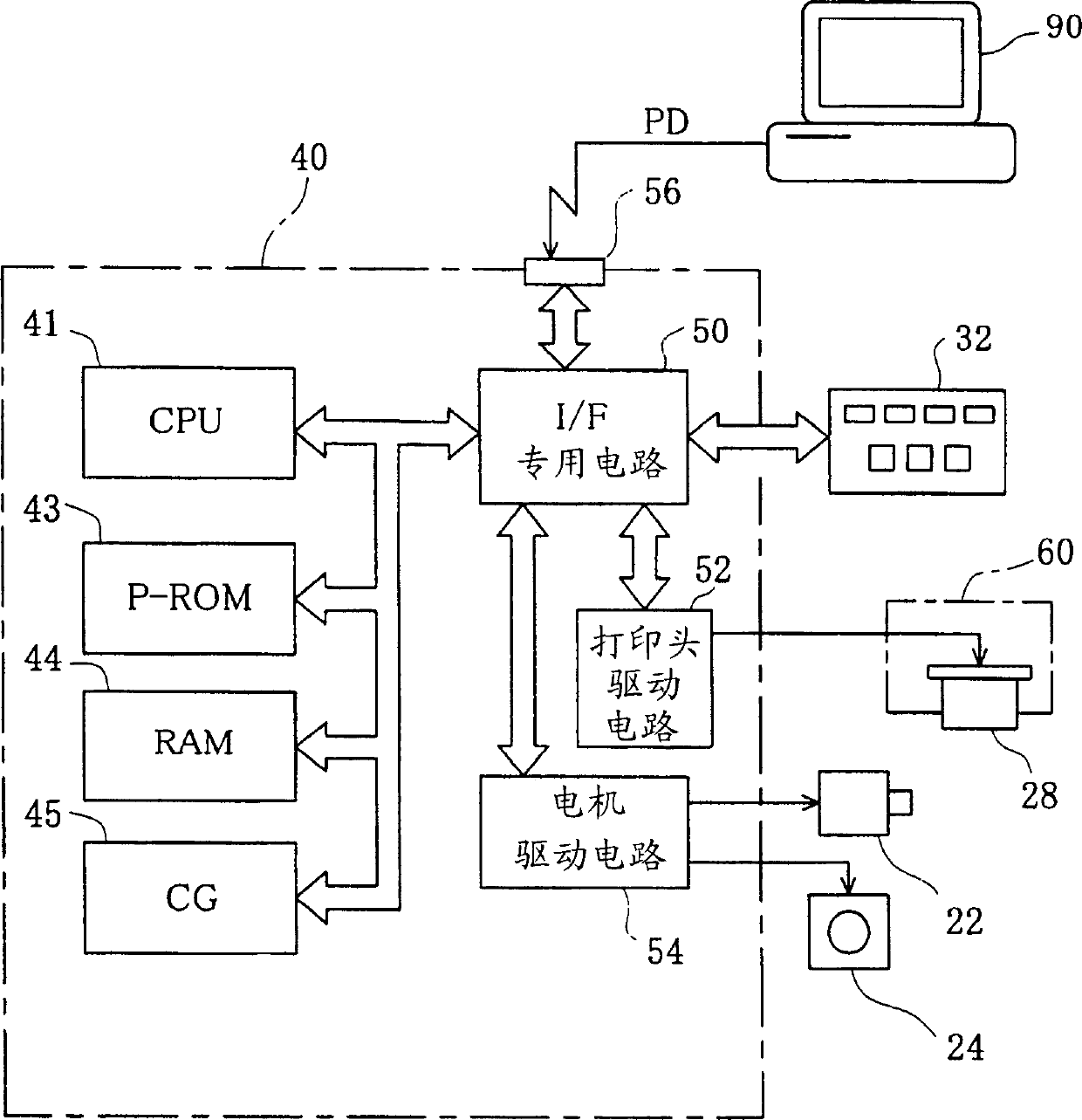

Method used

Image

Examples

example 1

[0168] In each of the above-mentioned embodiments, the ejection of the ink droplets on one main scanning line is completed by three main scans, but the number of main scans performed on one main scanning line is not limited to three times, and may be more than four times. .

Deformed example 2

[0170] In each of the above-described embodiments, a pixel pair is constituted by consecutive pixels in the main scanning direction, but a pixel pair may be constituted by consecutive pixels in the sub-scanning direction. In addition, in each of the above-described embodiments, a pixel pair is used as a unit of partial tone reproduction, but three or more consecutive pixels may be used as a unit of partial tone reproduction. In general, N pixels (N is an integer greater than or equal to 2) continuous in one of the main scanning direction and the sub scanning direction may be set as one unit of tone reproduction. At this time, the amount of ink that can be discharged at at least one pixel position among the N pixels is set to a value different from the amount of ink that can be discharged at other pixel positions.

[0171] In addition, in each of the above-described embodiments, the number of tones that can be partially reproduced is five, but the number of tones may be set to ...

Deformed example 3

[0173] The invention can also be applied to drum scan printers. In a drum scanning printer, the drum rotation direction is the main scanning direction, and the carriage running direction is the sub scanning direction. Furthermore, the present invention can be applied not only to inkjet printers but also to printing devices that generally print on the surface of a printing medium with a print head having a plurality of nozzles. Examples of such printing devices include facsimile devices, copying devices, and the like.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap