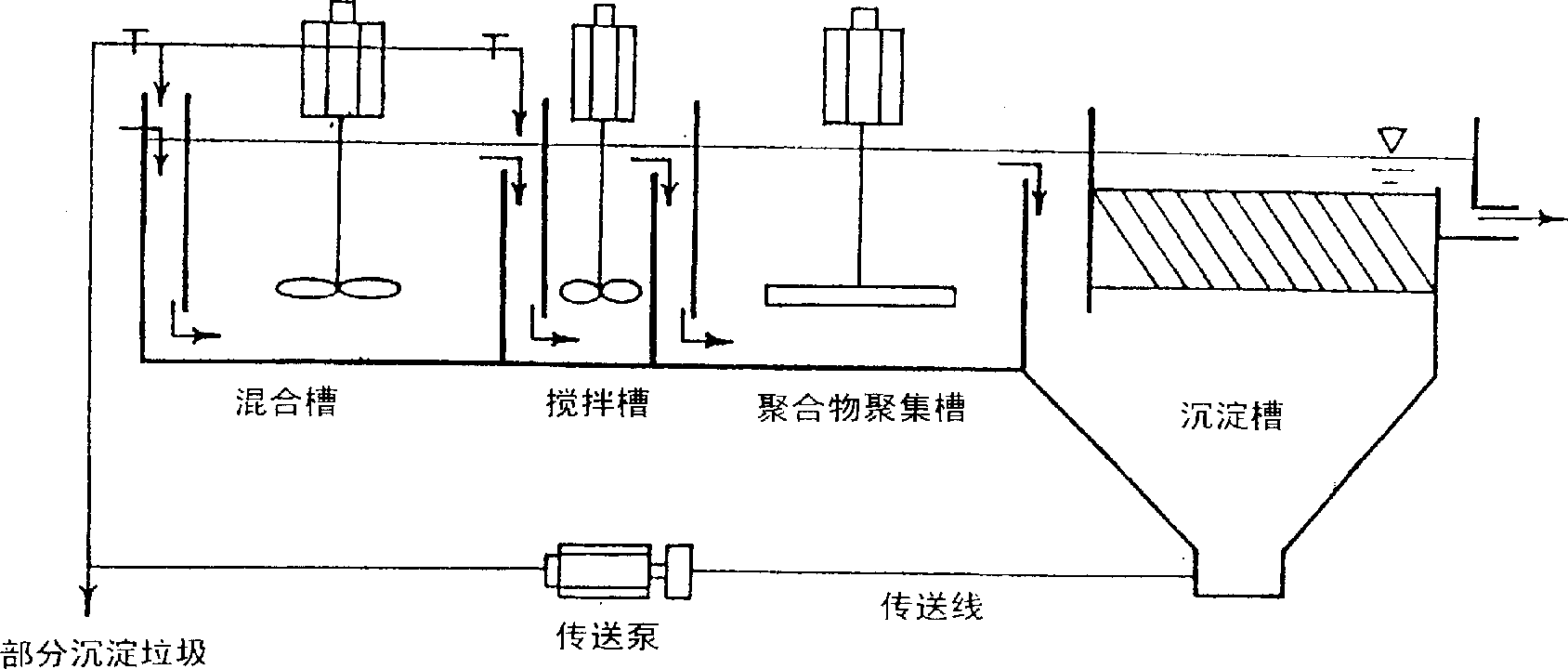

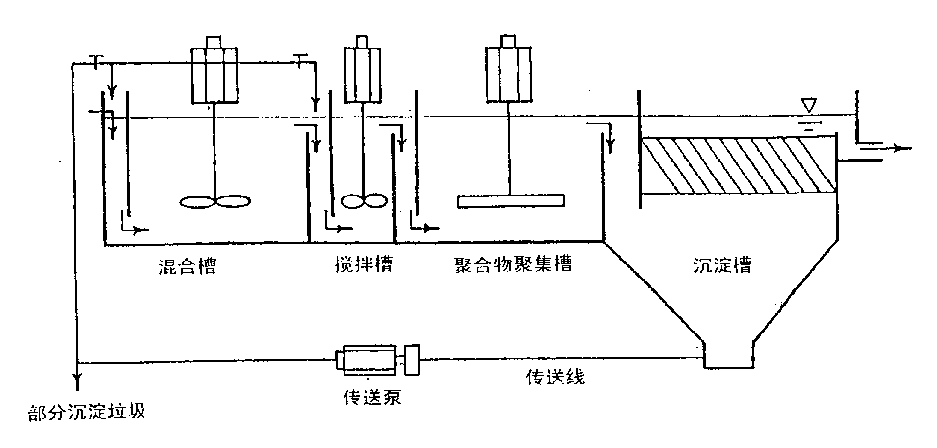

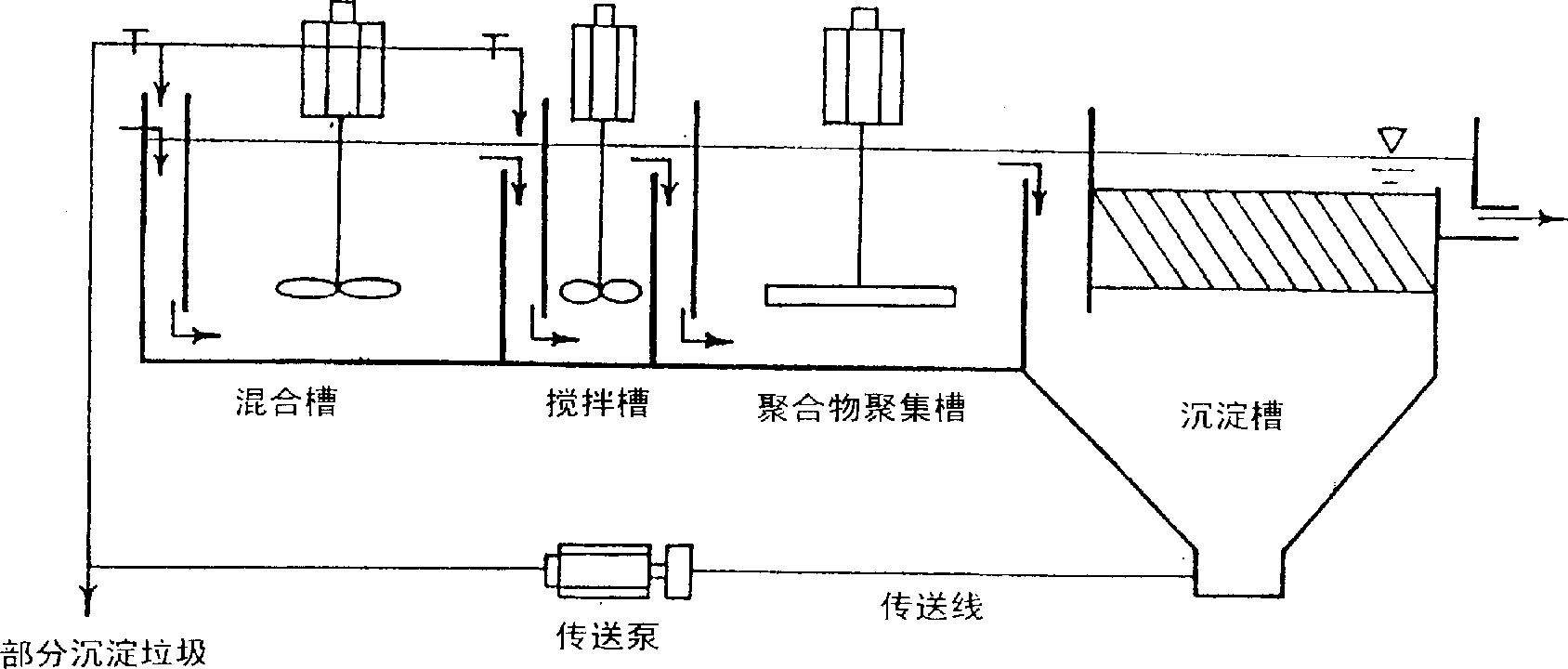

Rapid coagulation-flocculation and sedimentation type waste water treatment method

A flocculation and sedimentation technology, which is applied in the field of high-speed coagulation-flocculation and sedimentation, can solve secondary pollution and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] (1)

[0031] In particular, it can be seen from the above table that no matter how much Aqua#219, alum and ferric chloride are added, the removal efficiency of total phosphorus is over 90%, and the removal efficiency of BOD and COD is also satisfactory.

Embodiment 2

[0033] (1)

[0034] As can be seen from Table 2, the total phosphorus removal rate increased to over 95% with further addition of glass particles and diatomaceous earth components.

Embodiment 3

[0036] products

[0037] Table 3 shows that total phosphorus removal efficiencies as high as 83% or more can be achieved using only glass and diatomaceous earth, without any Aqua #210. A comparison of (1) and (2) in the case of using only glass shows that COD, TP and TN are removed more efficiently with higher amounts of (2) than with lower amounts of (1) high. On the other hand, in the case of using glass particles together with diatomaceous earth, a comparison of (3) and (4) shows that increasing the amount of glass has no appreciable effect on the removal efficiency of TP and TN, but only It has a slight influence on the removal efficiency of BOD and COD. By using only glass particles without diatomaceous earth (1) with invariant glass particles and diatomaceous earth (3) and with only glass particles without diatomaceous earth (2) with invariant glass particles Compared with (4) of diatomite, it can be seen that (1) and (2) without diatomite are better in ter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com