Equipment for treating industrial waste gas of plasma in low temperature

A technology of low-temperature plasma and industrial waste gas, which is applied in the direction of plasma, electrical components, separation methods, etc., can solve the problems of complex reactor production, difficult maintenance, low energy utilization rate, etc., and achieve a wide range of waste gas treatment, installation and maintenance Simple, energy-efficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

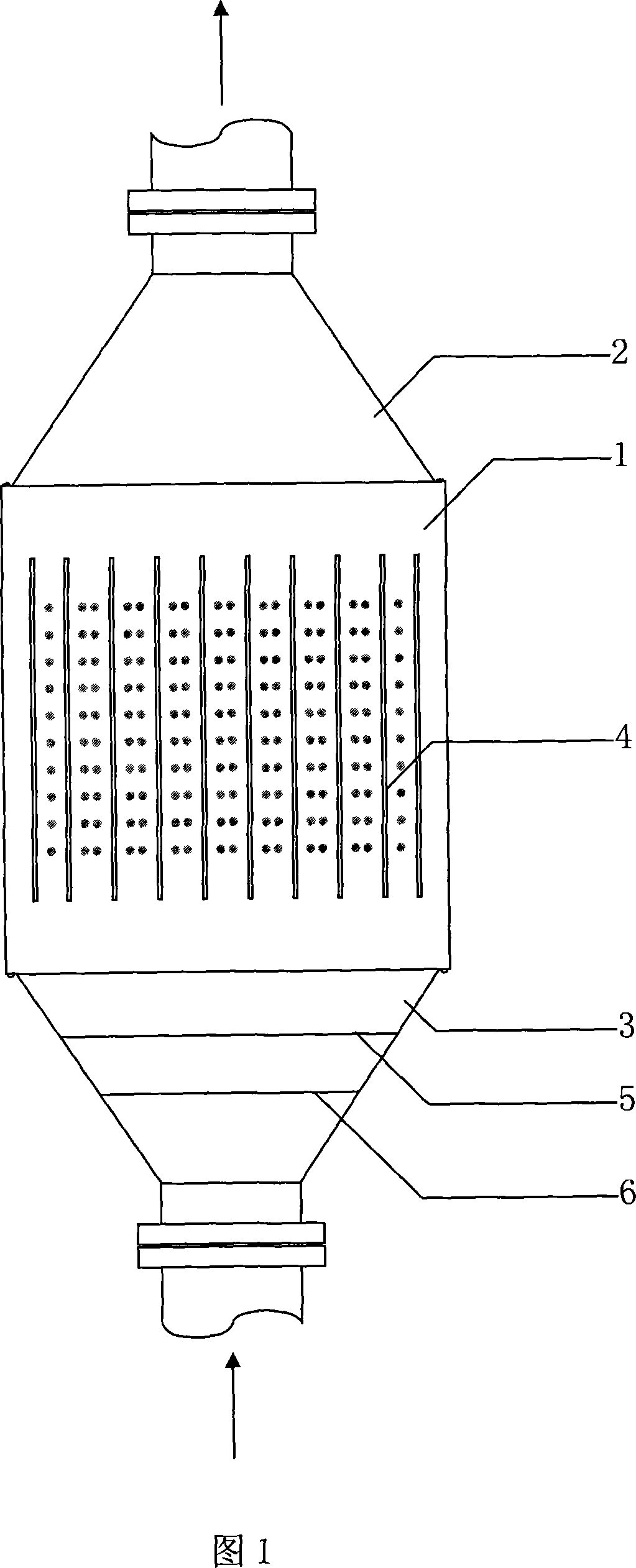

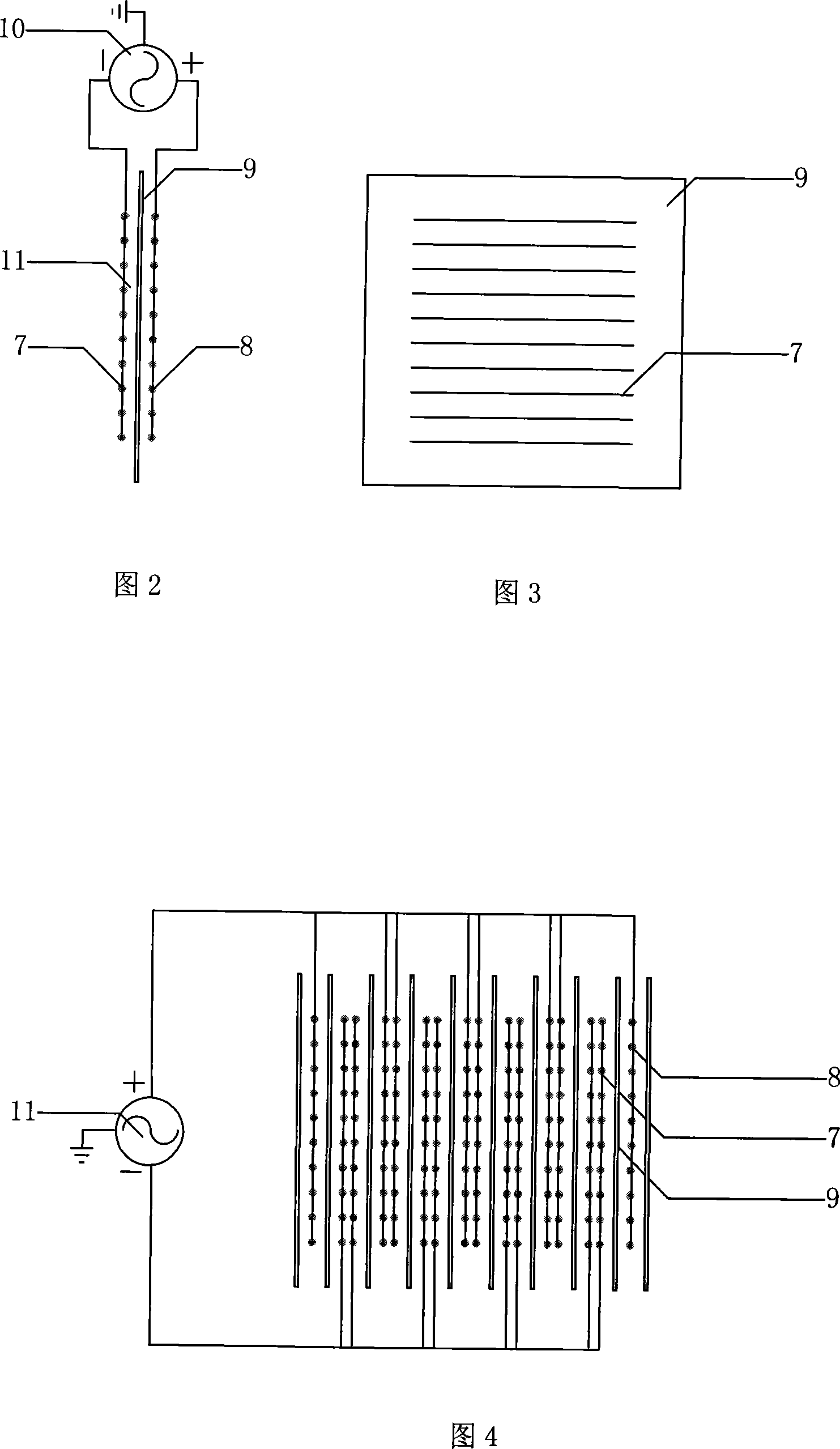

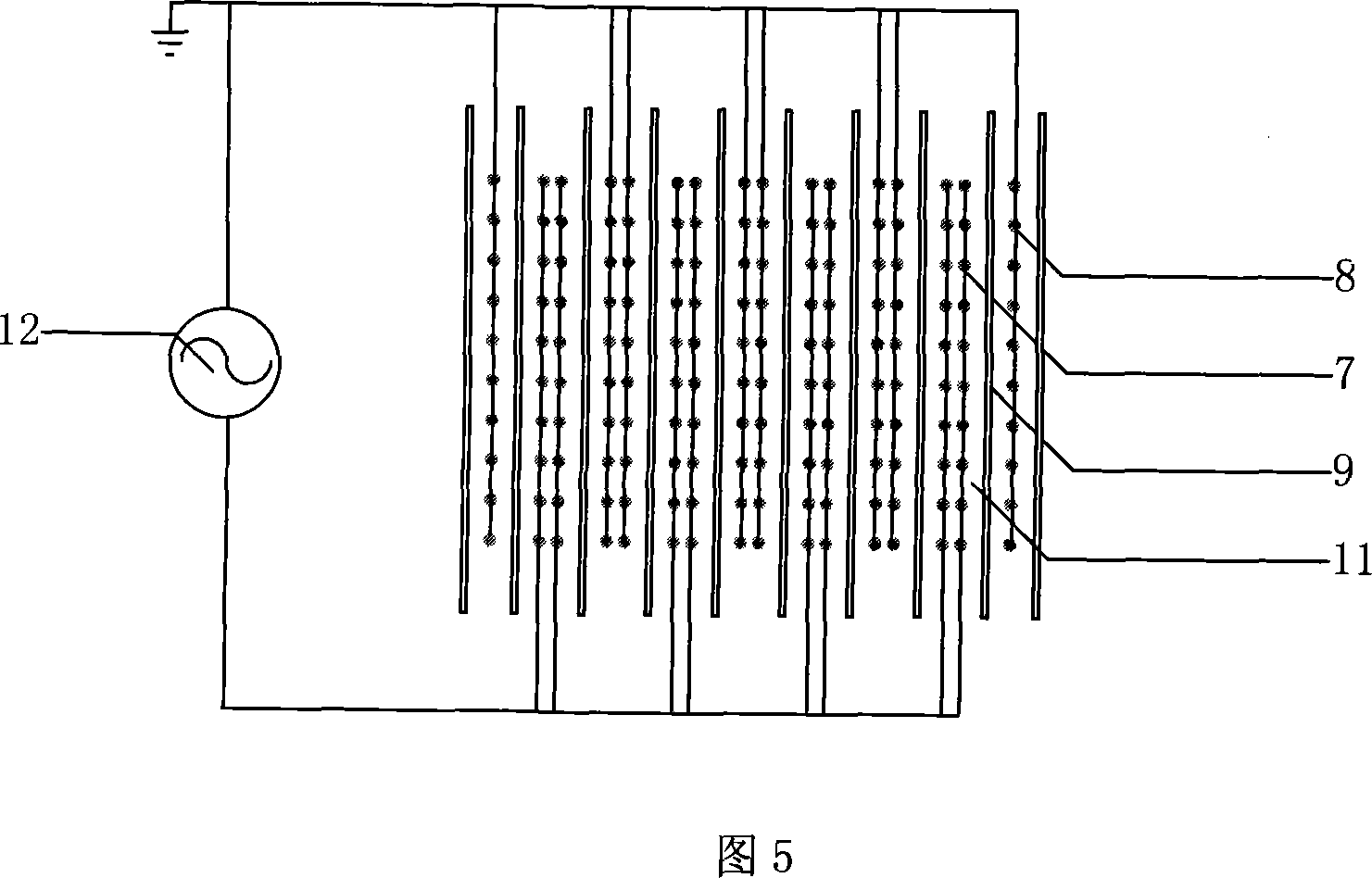

[0024] The present invention is a low-temperature plasma industrial waste gas treatment device, the structure of which is shown in Figure 1. The low-temperature plasma waste gas treatment device of the present invention adopts a wire plate structure, and consists of a low-temperature plasma discharge plate 4, a power supply and a corresponding housing. Composed of frame 1, upper interface 2 and lower interface 3, etc. Among them, the number of low-temperature plasma discharge plates 4 is 1 to 1000, which are arranged in parallel in the middle frame 1 of the shell. Theoretically, more low-temperature plasma discharge panels 4 can be arranged in parallel in the frame 1 of the housing. The upper interface 2 and the lower interface 3 are trumpet-shaped, and the large trumpet-shaped openings are fixedly connected to both sides of the middle frame 1 of the housing, and the small trumpet-shaped openings are respectively connected to the air intake pipe and the exhaust pipe. The trum...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap