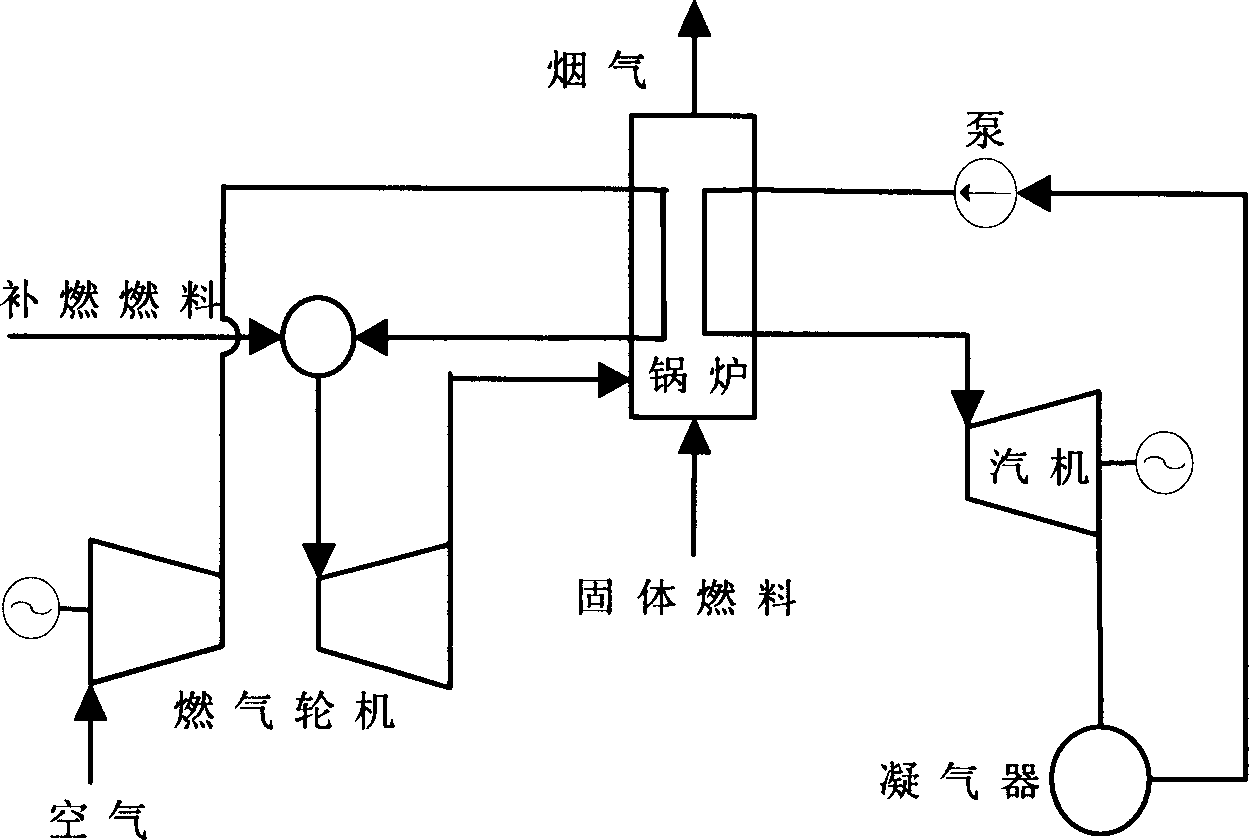

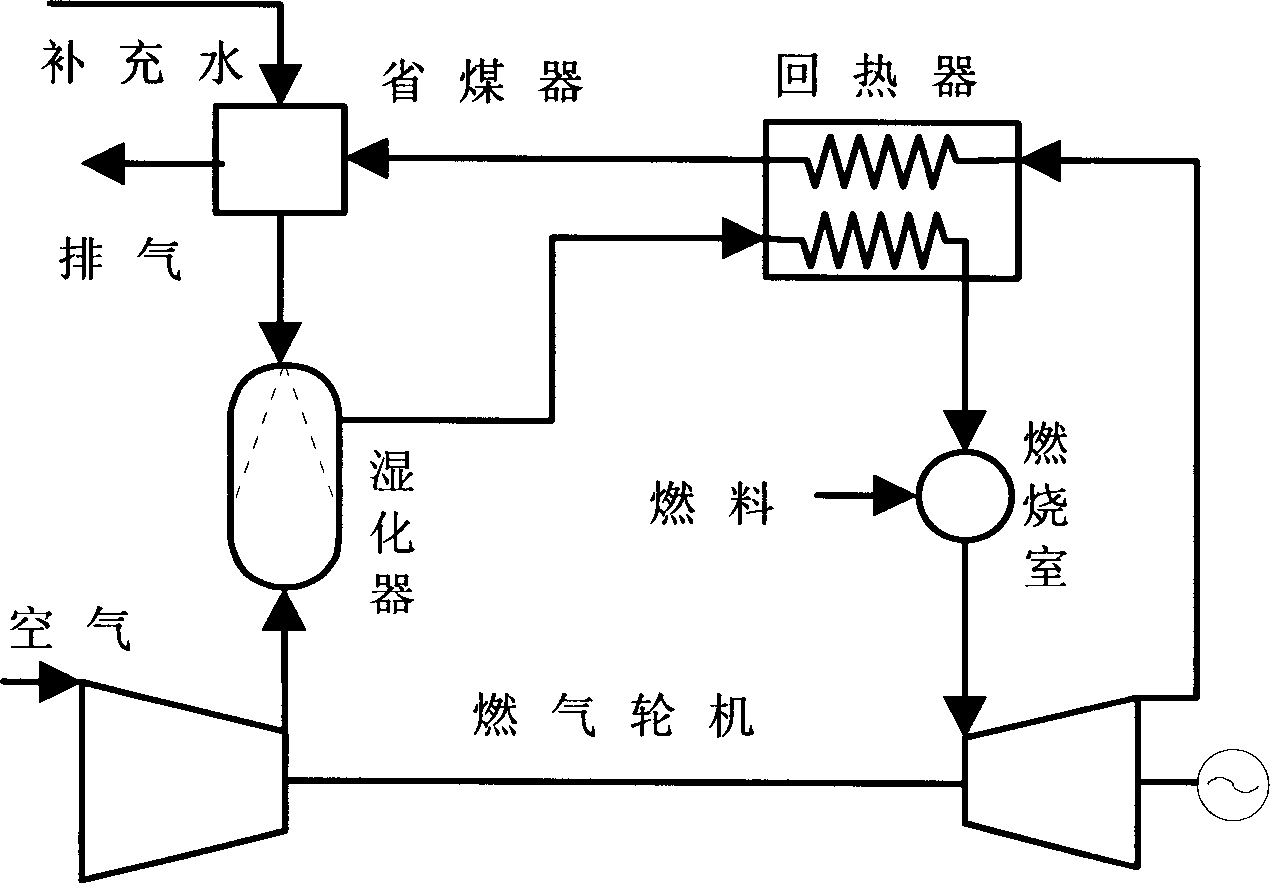

External combustion wet air gas turbine power generating system

A gas turbine and humid air technology, which is applied in gas turbine devices, machines/engines, mechanical equipment, etc., can solve problems such as difficulty in recovering water vapor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

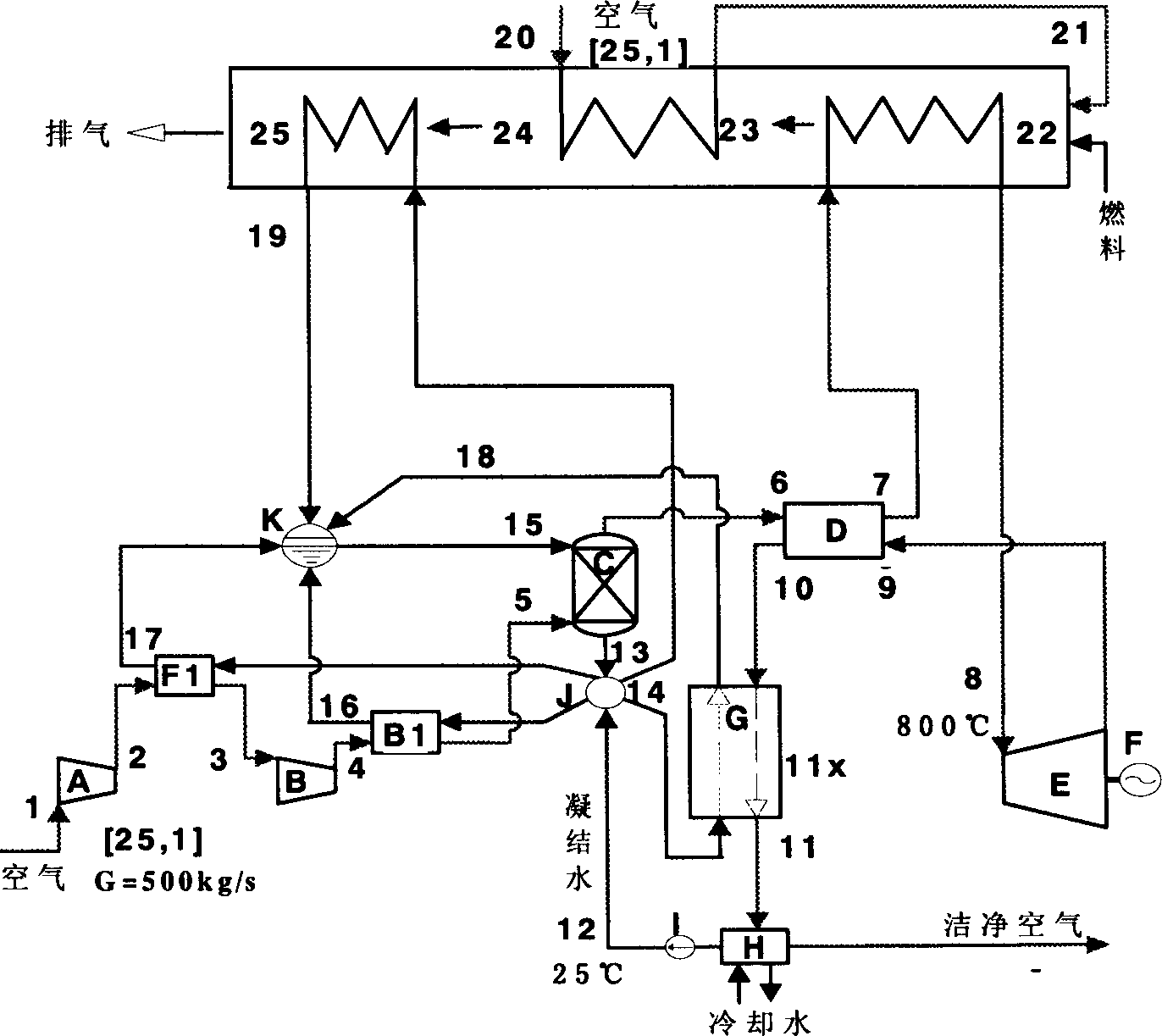

[0042] Refer to Table 1 and Table 2 for the performance parameters of a certain equilibrium working condition of the system of the present invention. The relevant conditions are: compressor efficiency 89%; turbine efficiency 91%; boiler efficiency 90%; total pressure loss is 10%; humidifier outlet water temperature is 5 times higher than humidifier inlet air corresponding adiabatic wet bulb temperature ℃. The coal used for burning is inferior coal, and its composition is: C-35.17%; H-1.69%; O-7.15%; N-0.525%; S-2.08%; A (ash) -46.13%; M (water) -7.26 %; calorific value 12928.33 (kJ / kg)

[0043] total pressure

12.00(bar)

Coal consumption

7.74(kg / s)

total pressure saturation temperature

187.96(℃)

boiler efficiency

90.00(%)

water vapor partial pressure

3.27(bar)

system efficiency

50.66(%)

partial pressure saturation temperature

136.51(℃)

the power

50730(KW)

[0044] Location ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap