Coupling mechanism of positive displacement swashplate compressor

A technology of swash plate and coupling mechanism, which is applied in the field of coupling mechanism, can solve the problems of low compressor volume efficiency, inability to control the compressor very accurately, and reduce the performance of the compressor, so as to improve performance, optimize manufacturing process, and improve orientation The effect of precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

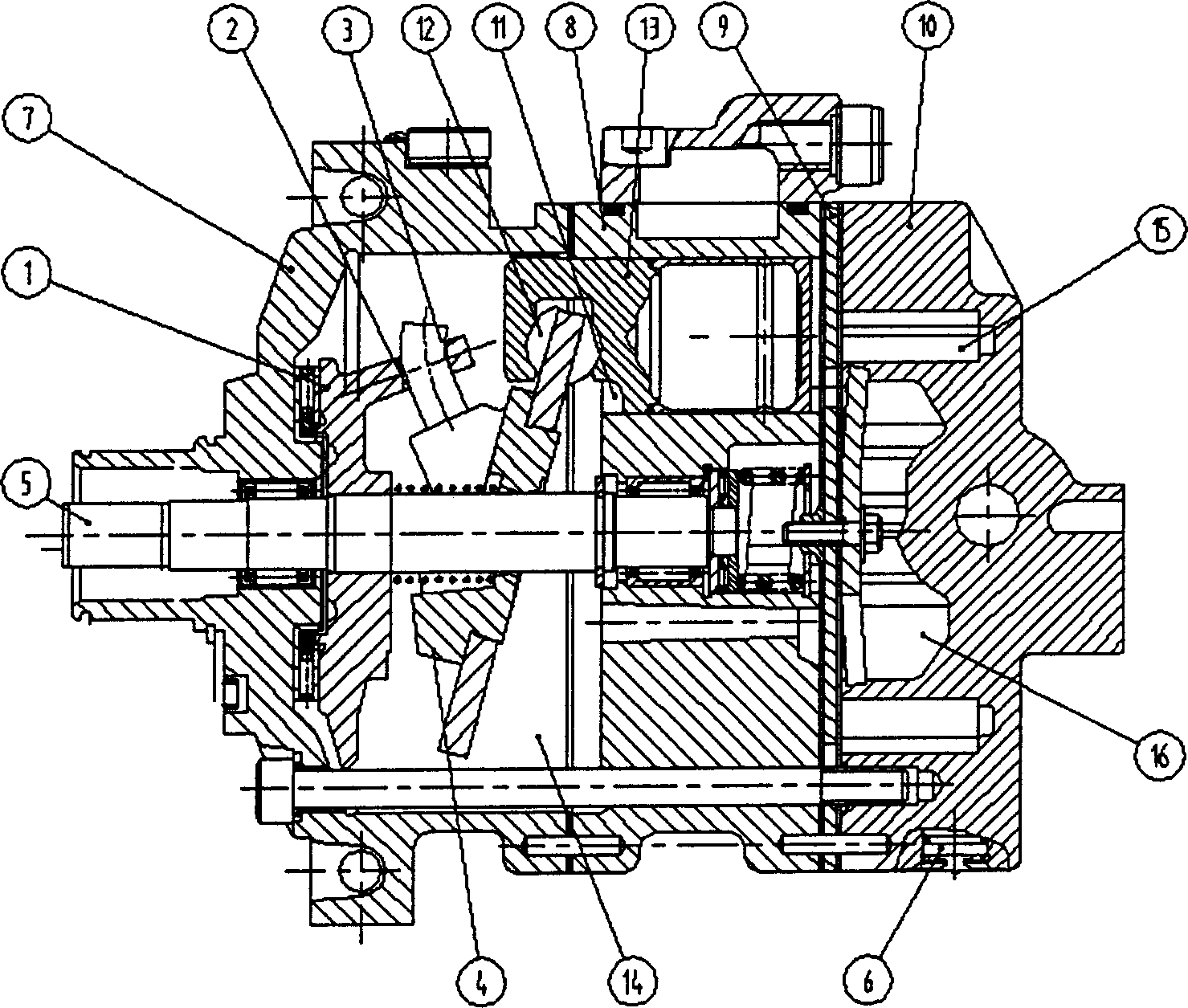

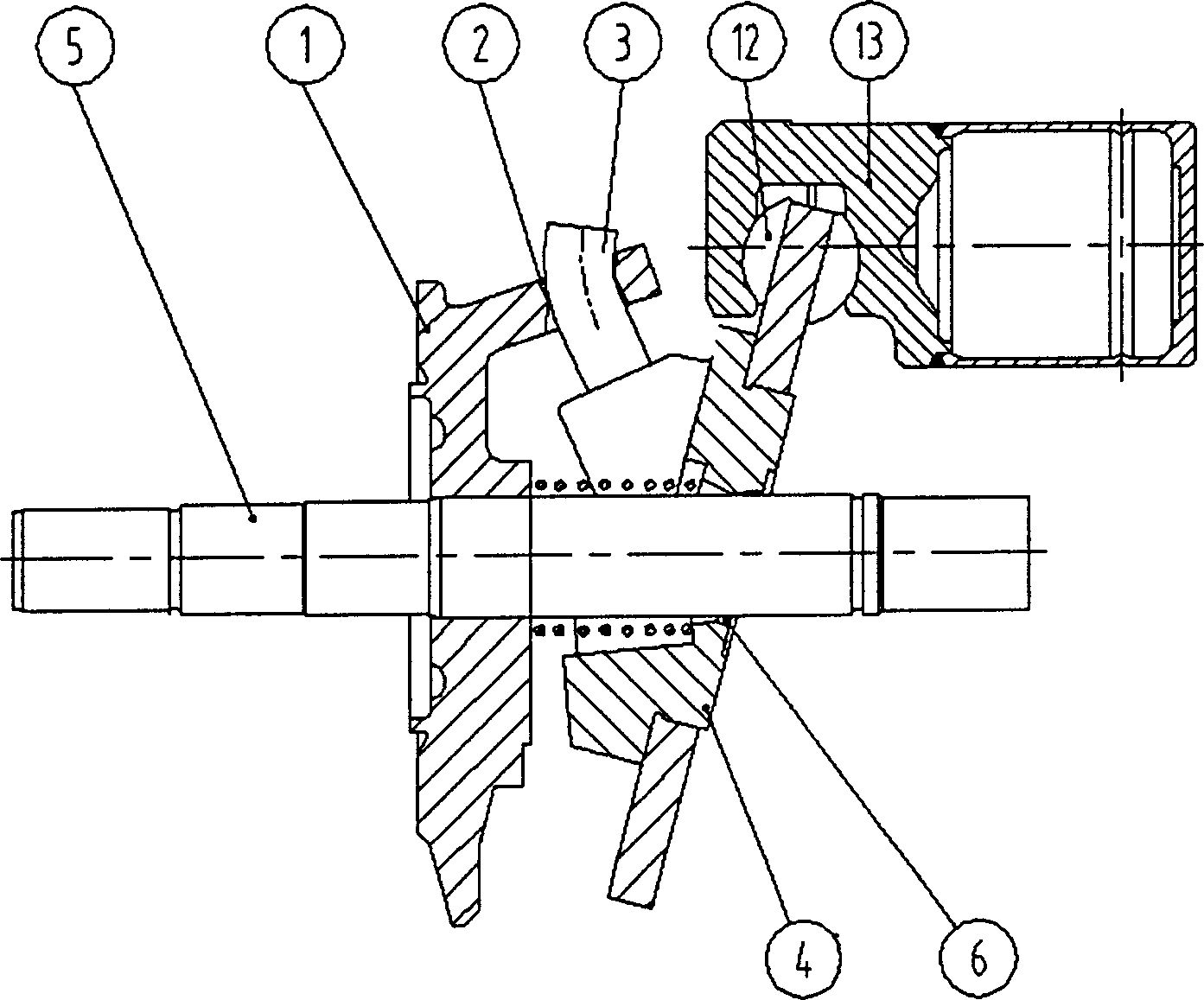

[0011] Such as Figure 1-3 As shown, the present invention is used in the variable displacement swash plate compressor. The compressor has a cylinder block 8, a front housing 7, a drive shaft 5 and a drive disc 1, a rear housing part 10, a swash plate 4, a guide arm 3, a sliding shoe 12, and a piston 13;

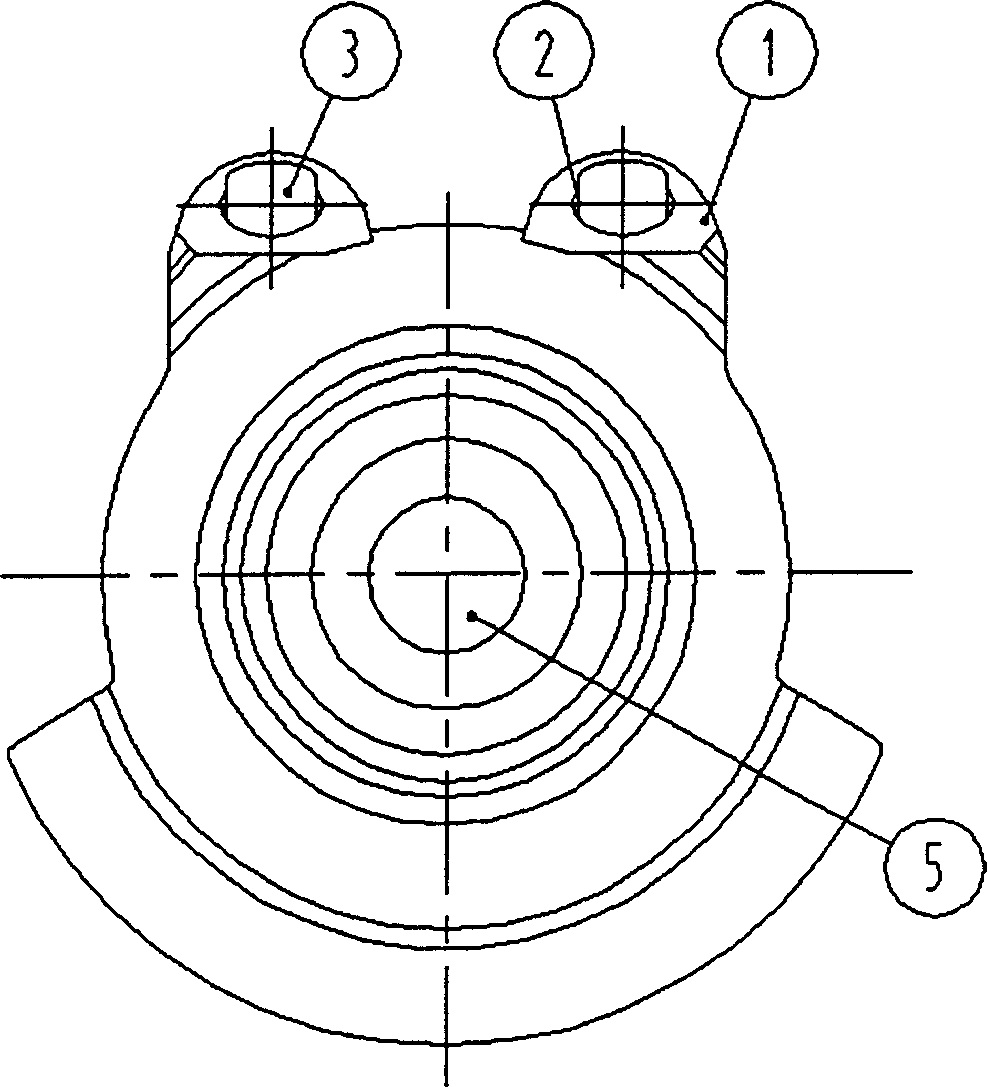

[0012] The front housing 7 closes the front end of the cylinder block 8, and forms a crank cavity 14 inside the cylinder block 8, and has several piston holes 11 arranged side by side to form the outer contour of the compressor;

[0013] The drive shaft 5 is supported by the cylinder block 8 and the front housing 7, and has an axis and can rotate around the axis;

[0014] The drive disc 1 is fixed on the drive shaft in the crank chamber 14, and the drive disc 1 is provided with two guide holes (or guide grooves) 2;

[0015] The rear housing 10 has an air suction chamber 15 and an exhaust chamber 16 and closes the rear end of the cylinder block, and the rear housing 10 is e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com