Self-balanced coal continuous gasification furnace

A self-balancing, gasification furnace technology, applied in the manufacture of combustible gas, petroleum industry, etc., can solve the problems of inability to effectively adjust the heat balance effect, and achieve continuous and stable operation, streamlined structure, and simplified operating procedures Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. These embodiments are used to illustrate the present invention, but not to limit the present invention.

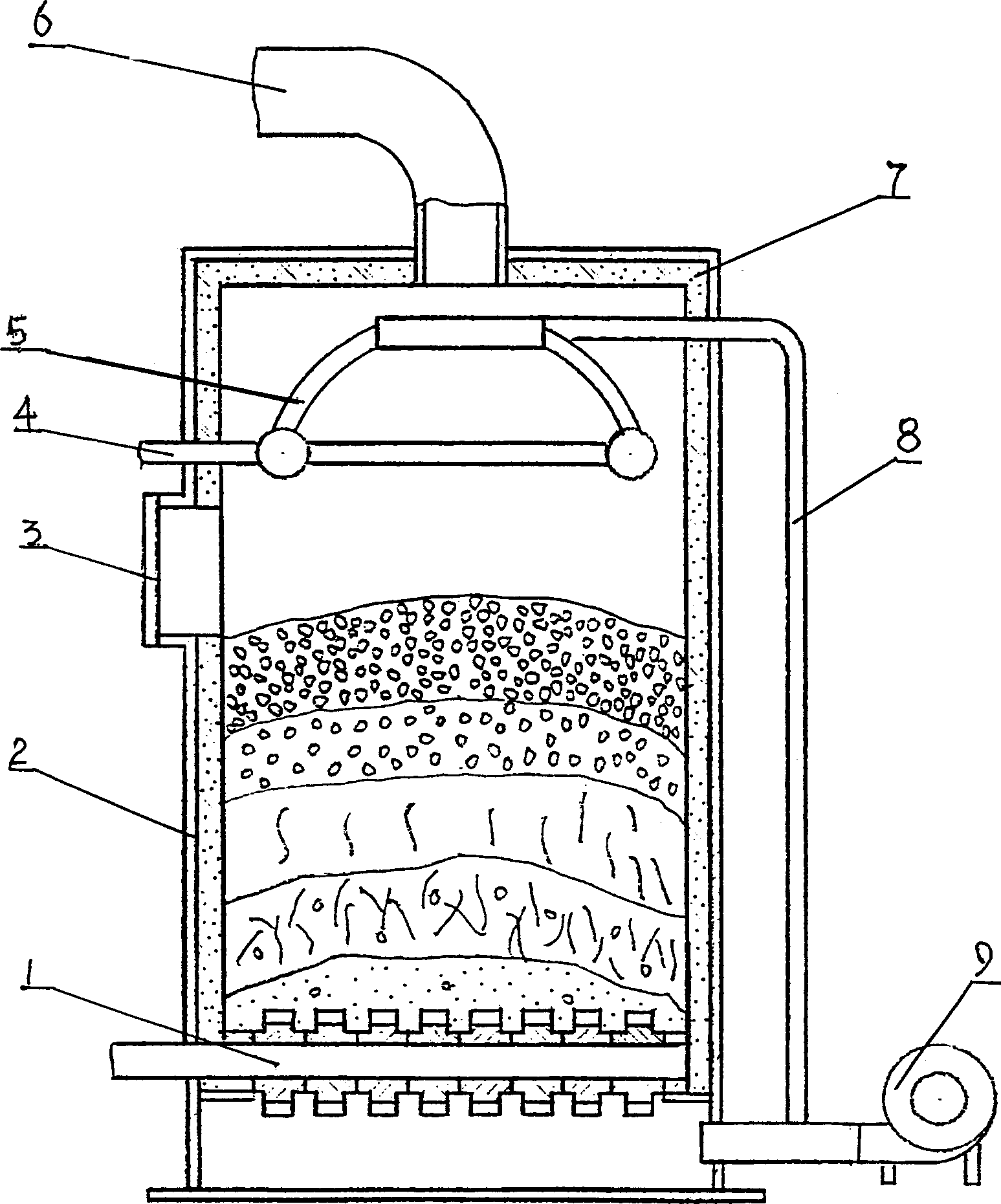

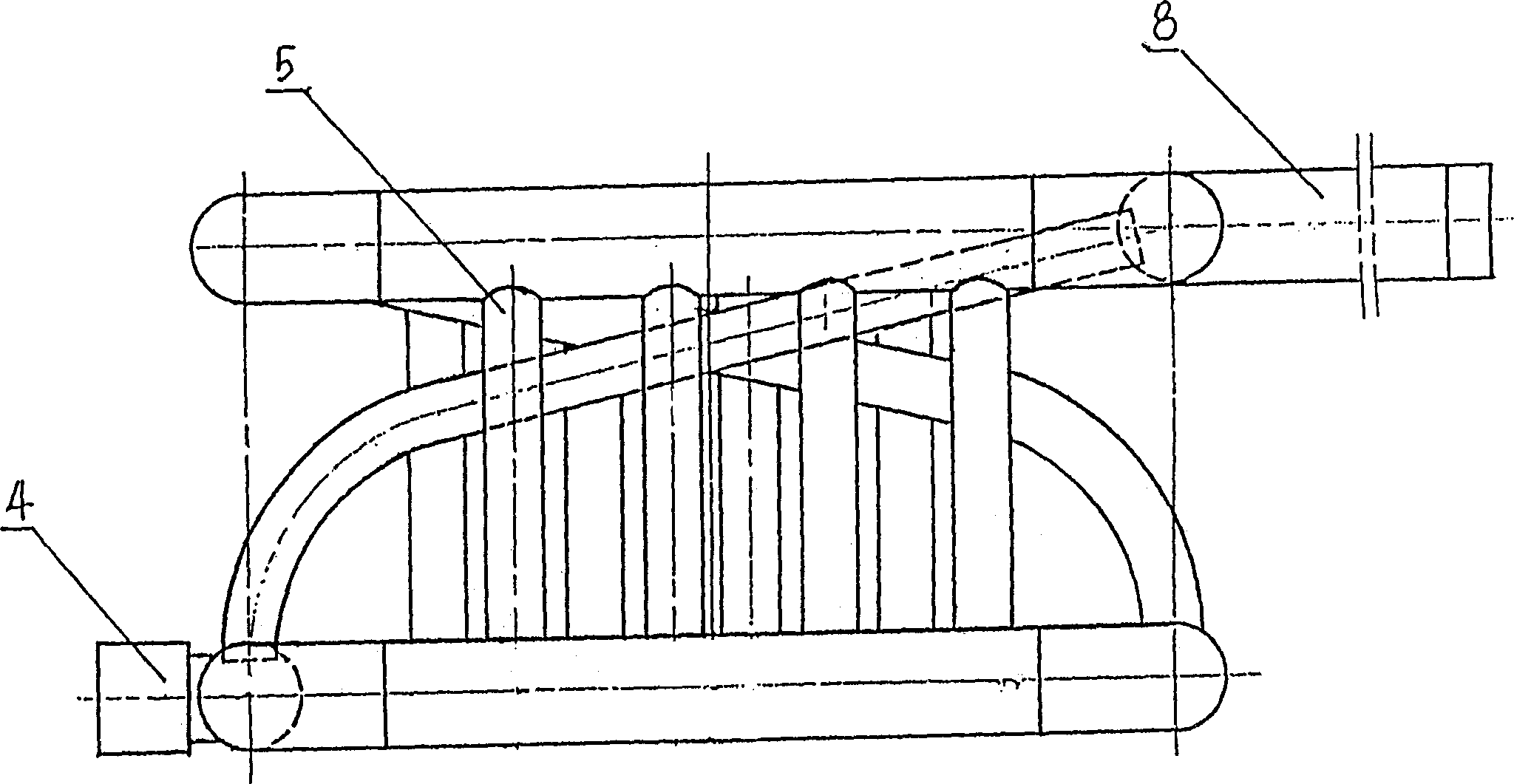

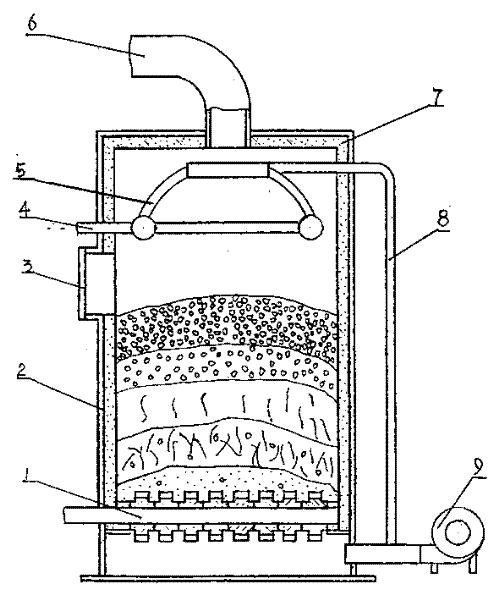

[0012] The self-balancing continuous coal gasifier includes a grate (1), a furnace body (2), and a gas delivery pipe (6). A steam generator (5) is arranged on the upper part of the furnace cavity corresponding to the fuel preparation layer, and the steam is generated The water inlet (4) of the device (5) is connected to the cold water source, and the steam outlet pipe (8) of the steam generator (5) is connected to the air outlet pipe of the blower (9), and the air outlet pipe of the blower (9) is passed into the furnace body Below the chamber grate (1). The steam generator (5) is a hollow water jacket placed on the upper part of the inner cavity of the furnace corresponding to the fuel preparation layer. The steam generator (5) can also be unifo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com