Manufacture of sealed hollow blocks

A manufacturing method and closed technology, applied in the direction of manufacturing tools, ceramic molding machines, molds, etc., can solve the problem of safety that cannot meet the requirements of mass production, and achieve the effect of smooth and closed surface, improving overall strength and reducing building load.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

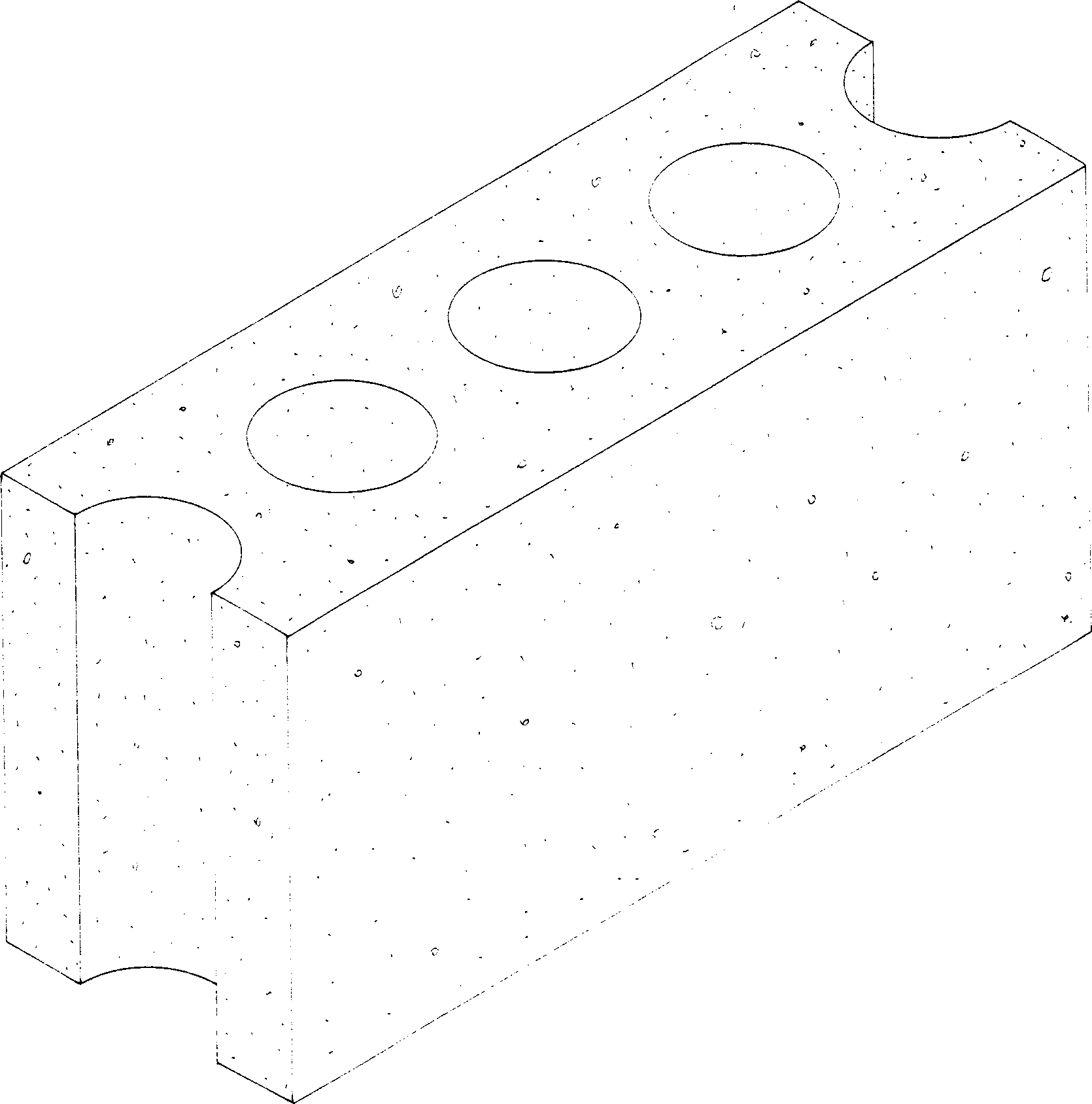

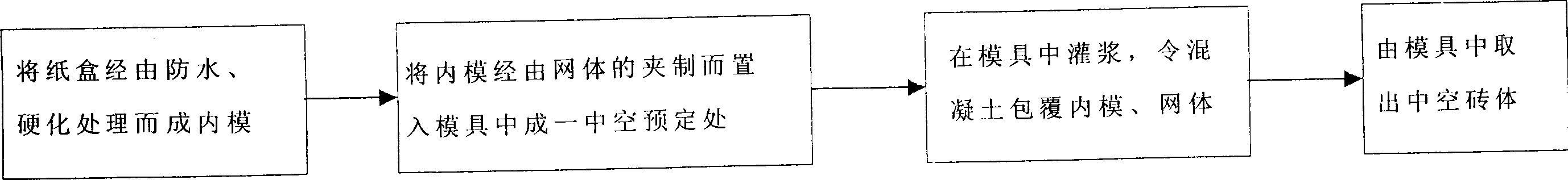

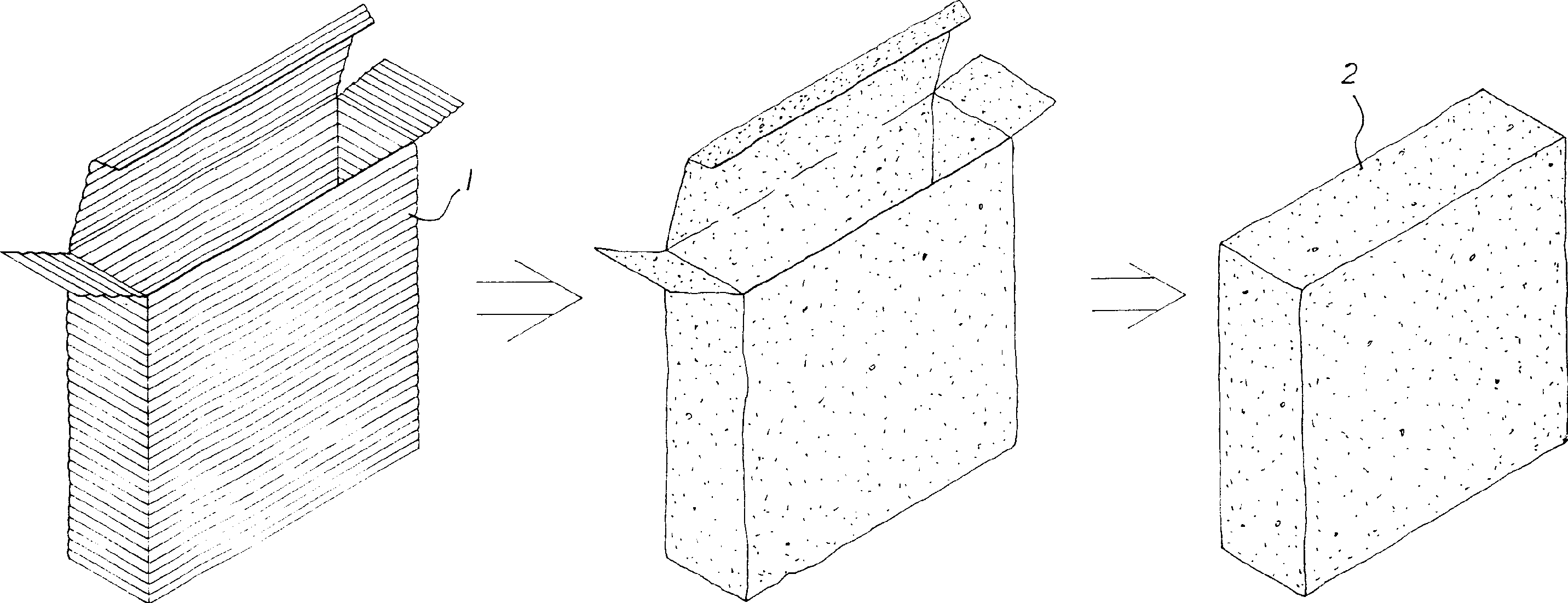

[0024] The present invention is a kind of manufacturing method of airtight hollow brick body, such as figure 2 As shown, the inner mold 2 made of the carton 1 with the help of waterproofing and hardening treatment is clamped by the net body 3 and then accommodated in the mold 4 to form a hollow predetermined place, so that the grout flows into the mold 4 and the concrete 5 is completely covered. The inner mold 2 and the mesh body 3 are formed to achieve the effect that the brick body 10 has a flat and airtight appearance and a hollow interior for weight reduction.

[0025] For above-mentioned manufacture method of the present invention, specifically enumerate embodiment as follows:

[0026] Making the inner mold 2: The carton 1 is waterproofed and hardened. Since the paper product has the disadvantage of becoming soft after absorbing water, if it is directly in contact with the concrete slurry, the carton 1 will quickly soften and become Deformation, even under the grouting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com