Pump device and method for generating adjustable constant fluid volume flow and its application

A volume flow, pump device technology, applied to the components of pumping devices for elastic fluids, pumps for special fluids, pump devices, etc., can solve problems such as leakage and achieve easy-to-implement effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

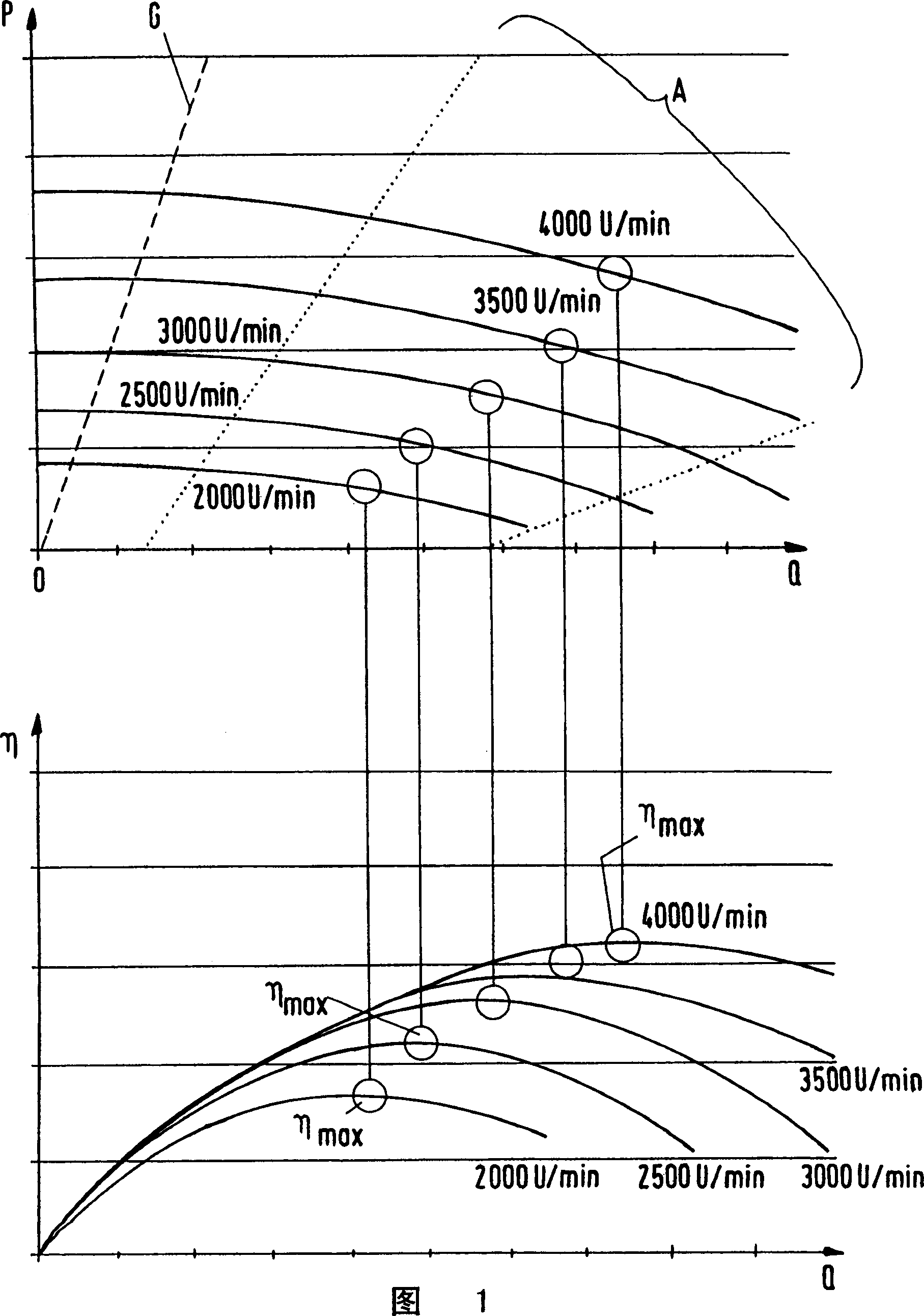

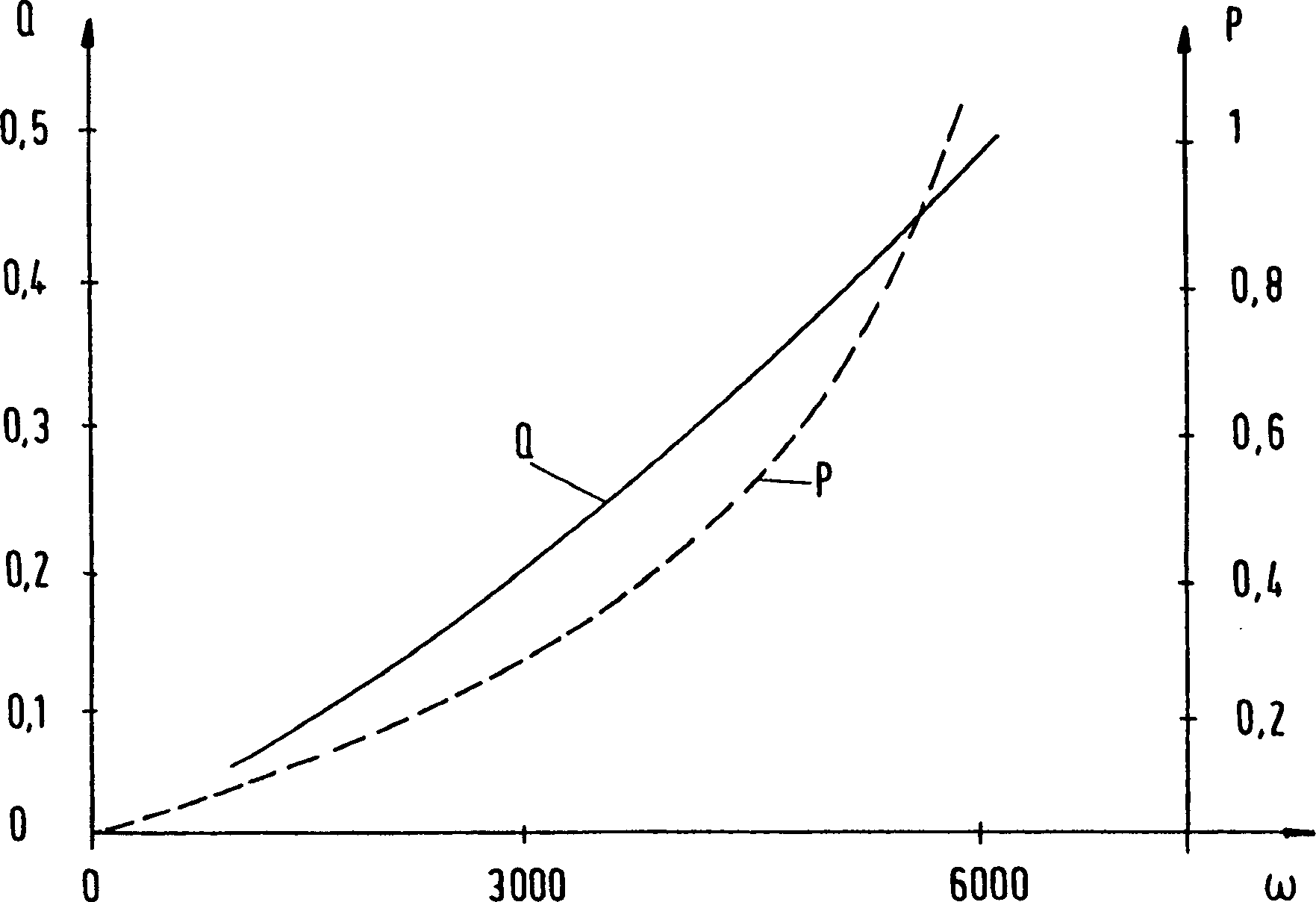

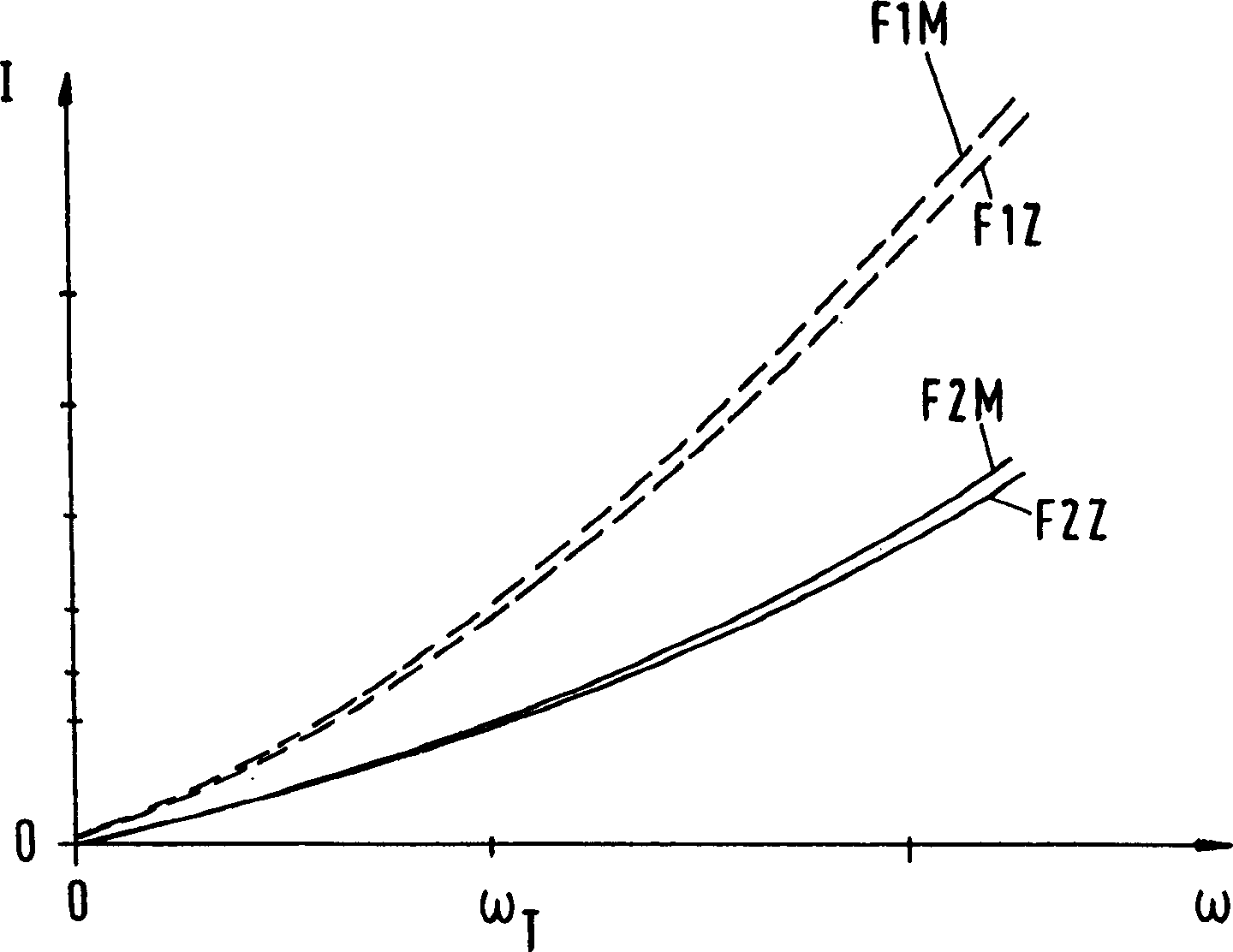

[0024] A method for producing an adjustable and approximately constant volumetric flow of a fluid is characterized in particular by the use of a rotary pump which operates at an efficiency of less than half the maximum efficiency of the rotary pump. Preferably, the efficiency is up to twenty percent of the maximum efficiency.

[0025] Figure 4 An embodiment configuration implementing the method of the invention is shown. Here, the rotary pump 1 is designed as a centrifugal pump with a rotor 10 whose inlet is connected to a reservoir 2 in which the fluid 5 to be conveyed is located. The outlet of the rotary pump 1 is connected via a fluid connection 4 to a doser 6 with a nozzle 61 .

[0026] A particularly important practical application of the method of the invention as part of a chemical mechanical polishing (CMP) process in the semiconductor industry is mentioned below by way of example. In these processes, a suspension (ie slurry) having very fine solid particles in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com