Axial vibration preventing mechanism and brushless motor having it

An axial vibration and configuration technology, which is applied to synchronous motors, electromechanical devices, and mechanical equipment with static armatures and rotating magnets. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Hereinafter, embodiments of the present invention will be described with reference to the drawings.

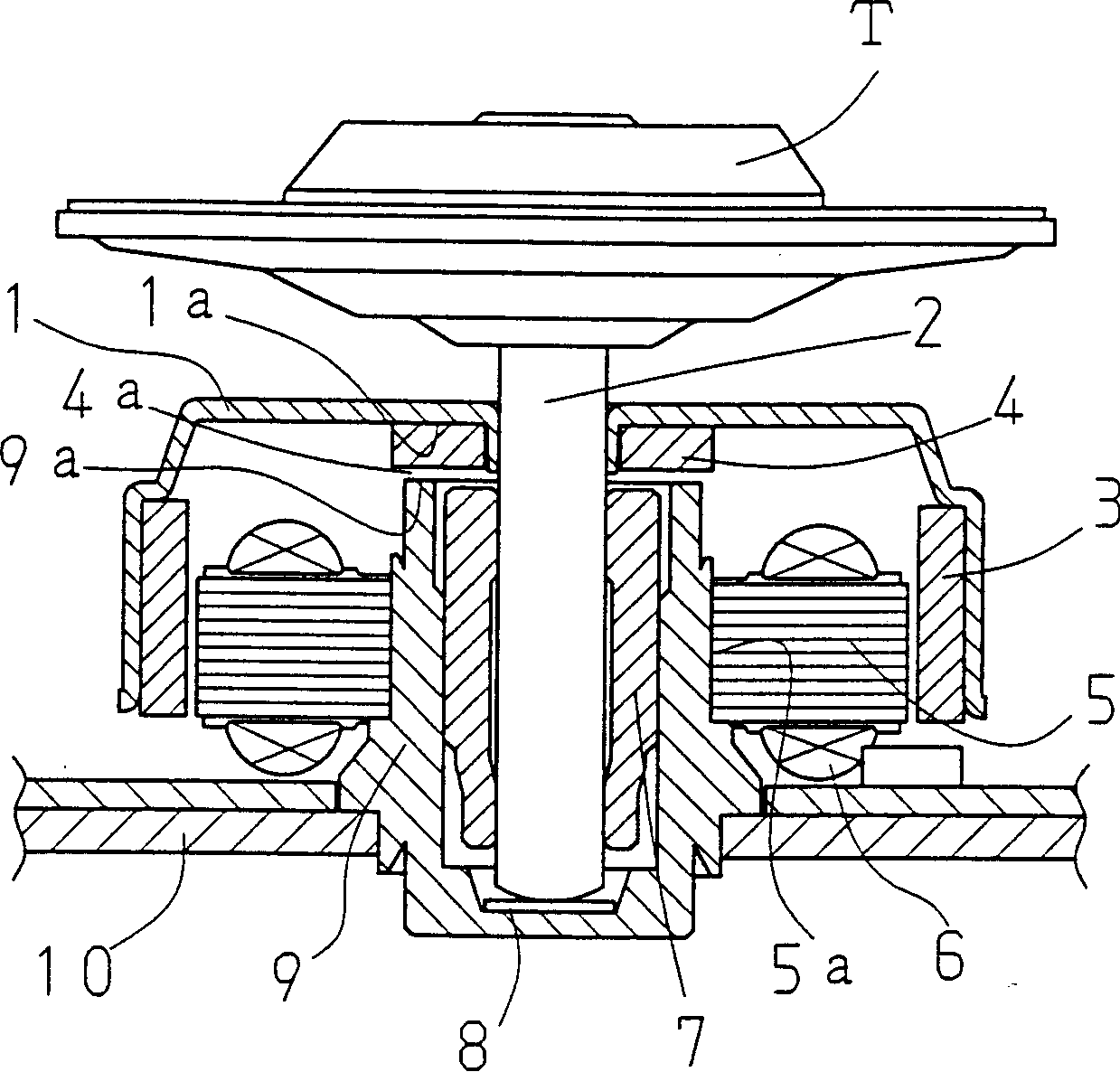

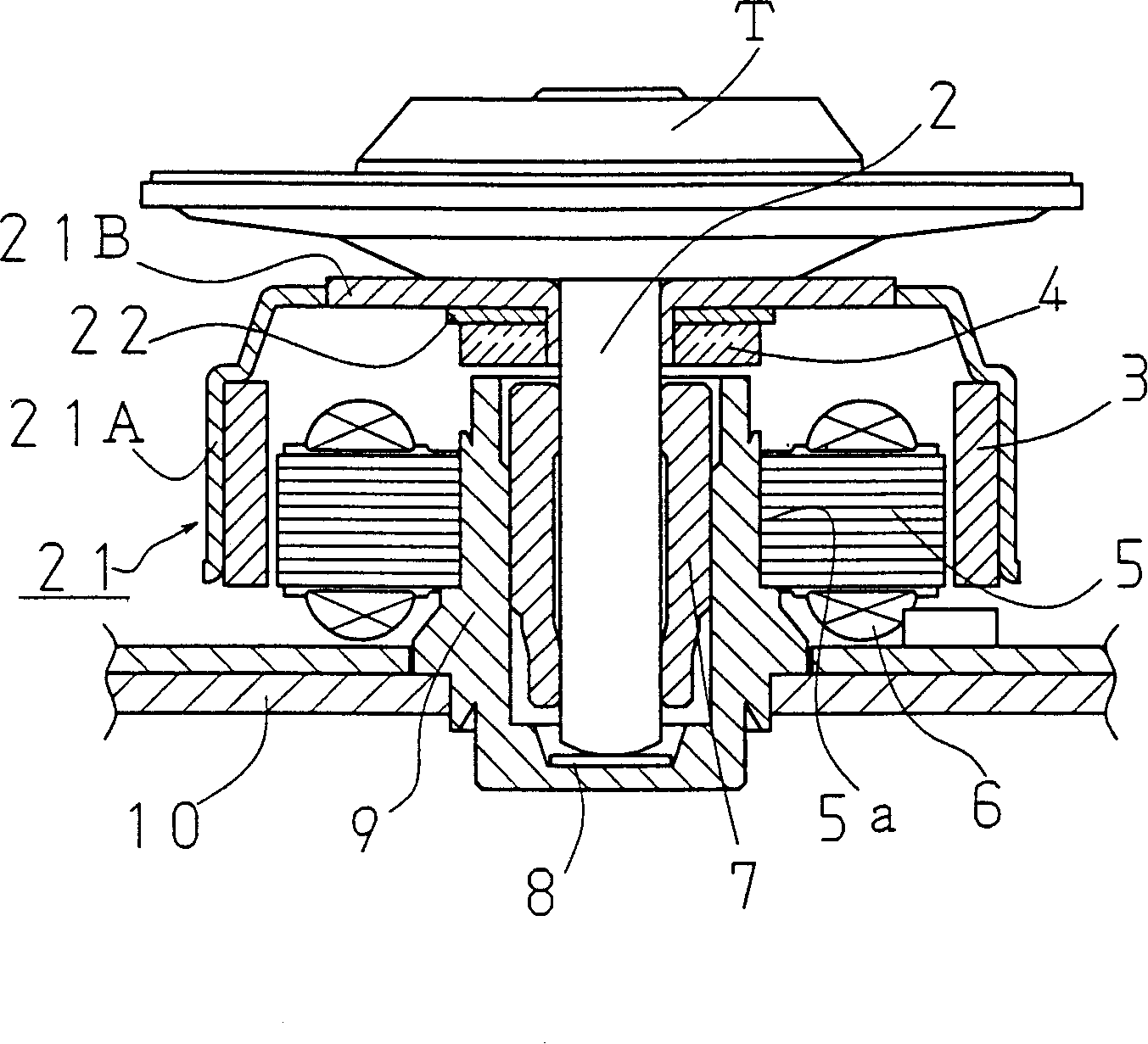

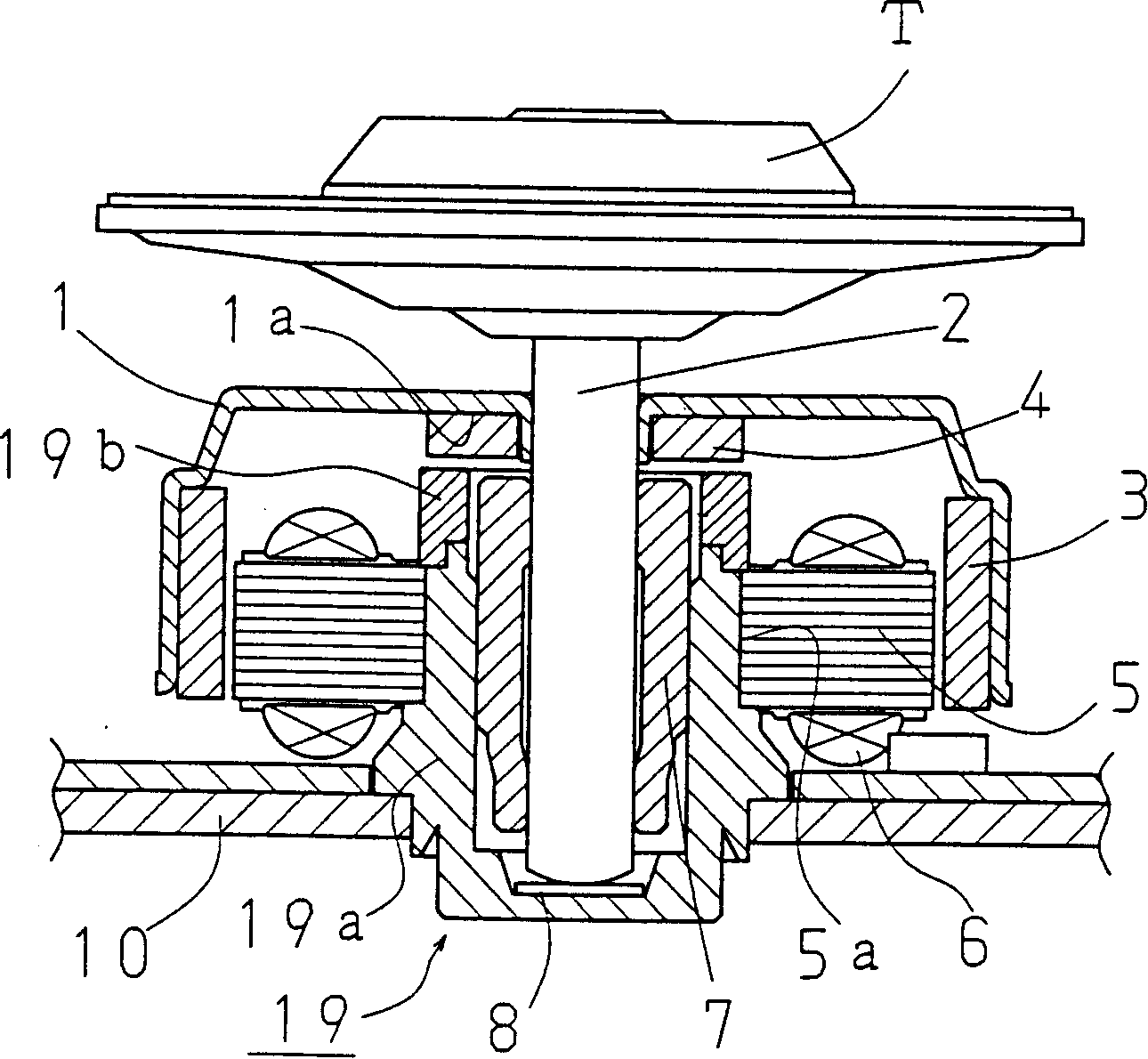

[0029] figure 1 In the center part of the rotor yoke 1 formed in an inverted cup shape, the shaft 2 is fastened; on the inner peripheral side of the yoke 1, the driving magnet 3 is fastened, and the shaft 2 is inserted into the rotor yoke 1. The ring-shaped generation pre-pressure magnet 4 is fastened on the peripheral surface. On the other hand, an armature coil 6 is wound around the stator core 5, and a bearing bracket 9 made of a magnetic material is inserted in the central annular portion 5a of the stator core 5, and a radial bearing 7 and a thrust bearing 8 are held inside it. ; The bearing bracket 9 is fastened on the stator base 10 .

[0030] The bottom 4a of the magnet 4 for preload generation and the opening 9a of the bearing bracket 9 are arranged to have a gap close to each other so as not to affect the rotation, and the turntable T on which the information...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com