Charging rate regulating circuit for battery group

A technology for adjusting the circuit and charging rate, applied in the direction of charging/discharging of secondary batteries, battery circuit devices, charge equalization circuits, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment

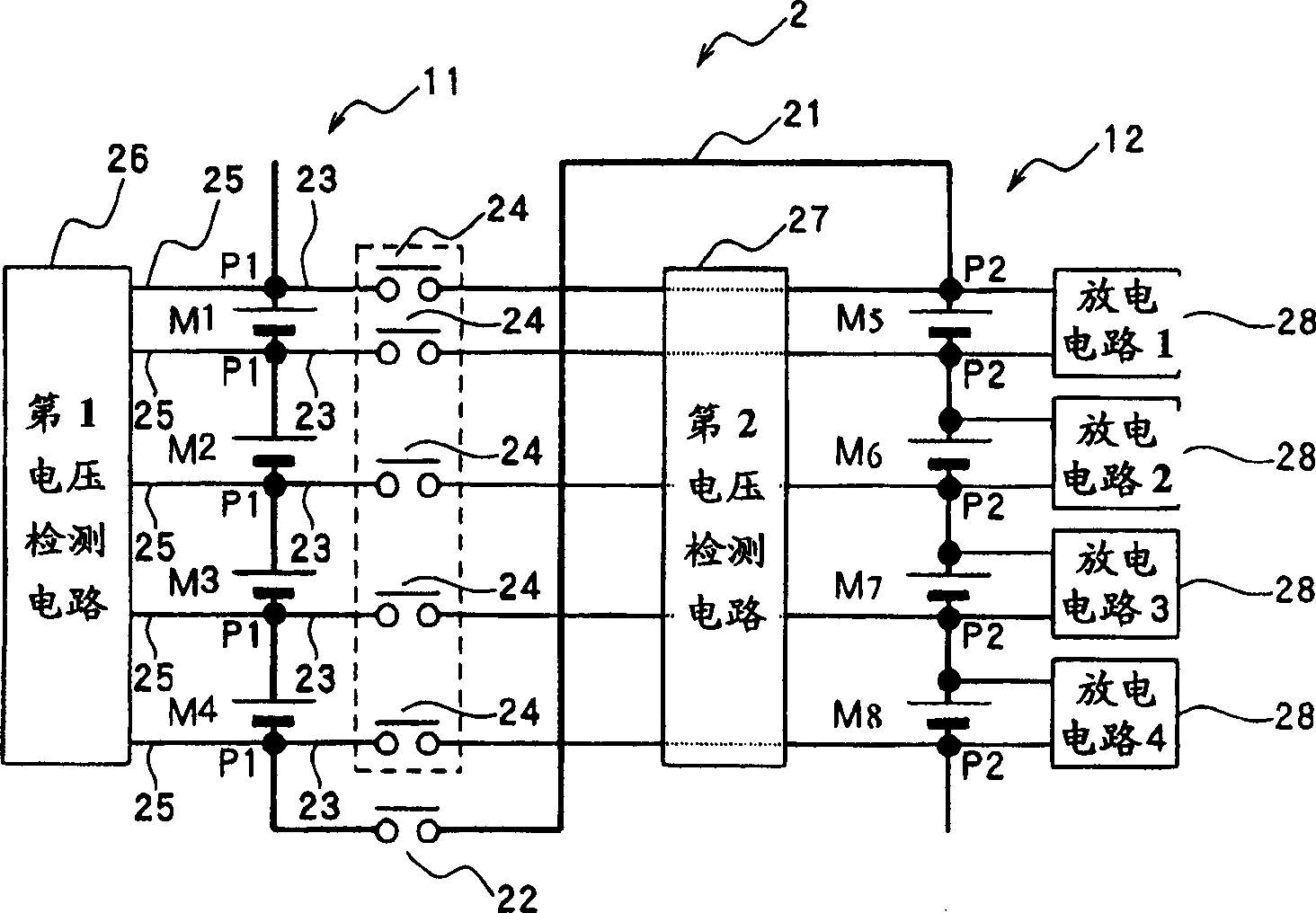

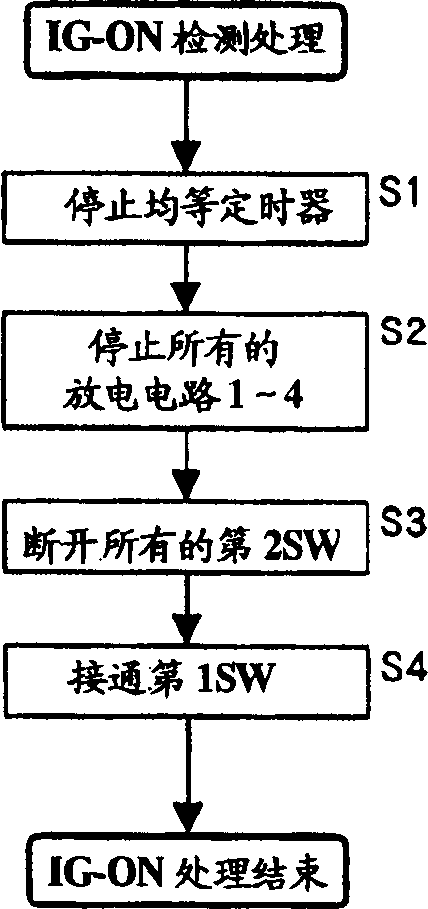

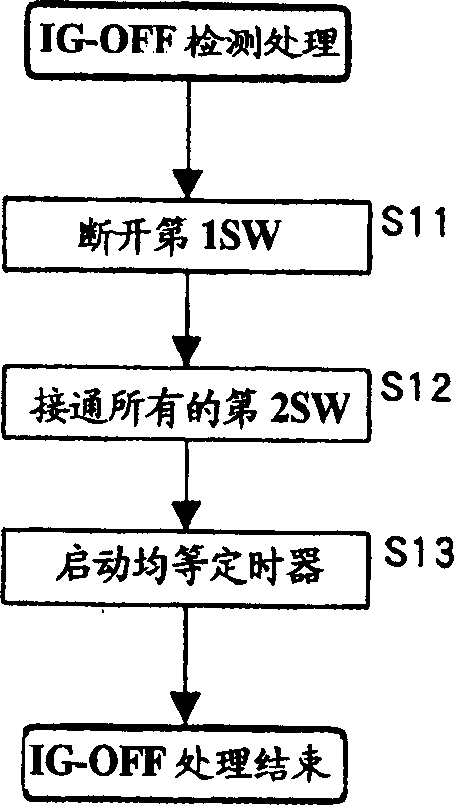

[0057] figure 1 The configuration of the charge rate adjustment circuit (2) for a battery pack composed of two battery blocks (11) (12) is shown. In the circuit (2), the first battery block (11) and the second battery block (12) are respectively constructed by using one or more rechargeable batteries as battery modules and connecting four battery modules in series. A series wire (21) is led out from the negative pole of the first battery block (11), and the front end of the series wire (21) is connected to the positive pole of the second battery block (12). The first switch (22) is inserted into the series line (21), and the two battery blocks (11) (12) are connected in series by the first switch (22). On the other hand, the first switch (22) is turned off. Open to cut off the connection of two battery blocks (11) (12).

[0058] Five parallel connection points P1 are set at the connection points between the two ends of the first battery block (11) and the battery modules M1...

no. 2 Embodiment

[0086] The charging rate adjustment circuit (3) of the present embodiment configures a resistor in the charging rate adjustment circuit of the first embodiment, such as Figure 5 As shown, five parallel wires (23) are respectively inserted into resistors (30). For example, when the maximum potential difference generated between the two battery modules corresponding to the first and second battery blocks (11) (12) is 1.2V, and the allowable current value of the second switch (24) is 2A, the resistance (30 ) can be set to a resistance value of 0.6Ω.

[0087] In the charging rate adjustment circuit (3) of the present embodiment, even if there is a maximum difference between the charging rates of the two battery modules corresponding to the first and second battery blocks (11) (12), when all the second When the switch (24) is set to be turned on, the second switch (24) will not flow a larger current than the allowable current value, which can prevent the second switch (24) from b...

no. 3 Embodiment

[0101] Figure 7 The configuration of the charging rate adjustment circuit (4) of this embodiment is shown. The charging rate adjustment circuit (4) is a circuit for a battery pack composed of three battery blocks (11) (12) (13), from the first battery block (11) and the second battery block (12) The negative poles lead out series wires (41) respectively, and the front end of the series wires (41) drawn out from the negative pole of the first battery block (11) is connected to the positive pole of the second battery block (12). On the other hand, the front end of the series wire (41) drawn from the negative electrode of the second battery block (12) is connected to the positive electrode of the third battery block (13). Insert the first switch (42) in each series line (41), and connect the first to third battery blocks (11) (12) (13) in series by turning on the two first switches (42) (42) , On the other hand, the connection of the first to third battery blocks (11) (12) (13...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com