Fuel device and pump, injector

A fuel injection and injector technology, applied in the direction of fuel injection pump, fuel injection device, liquid fuel feeder, etc., can solve the problems of inability to supply fuel, lower fuel pump efficiency, lower fuel metering accuracy, etc., to prevent garbage and The effect of dust intrusion, improved freedom of arrangement, and elimination of arrangement space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

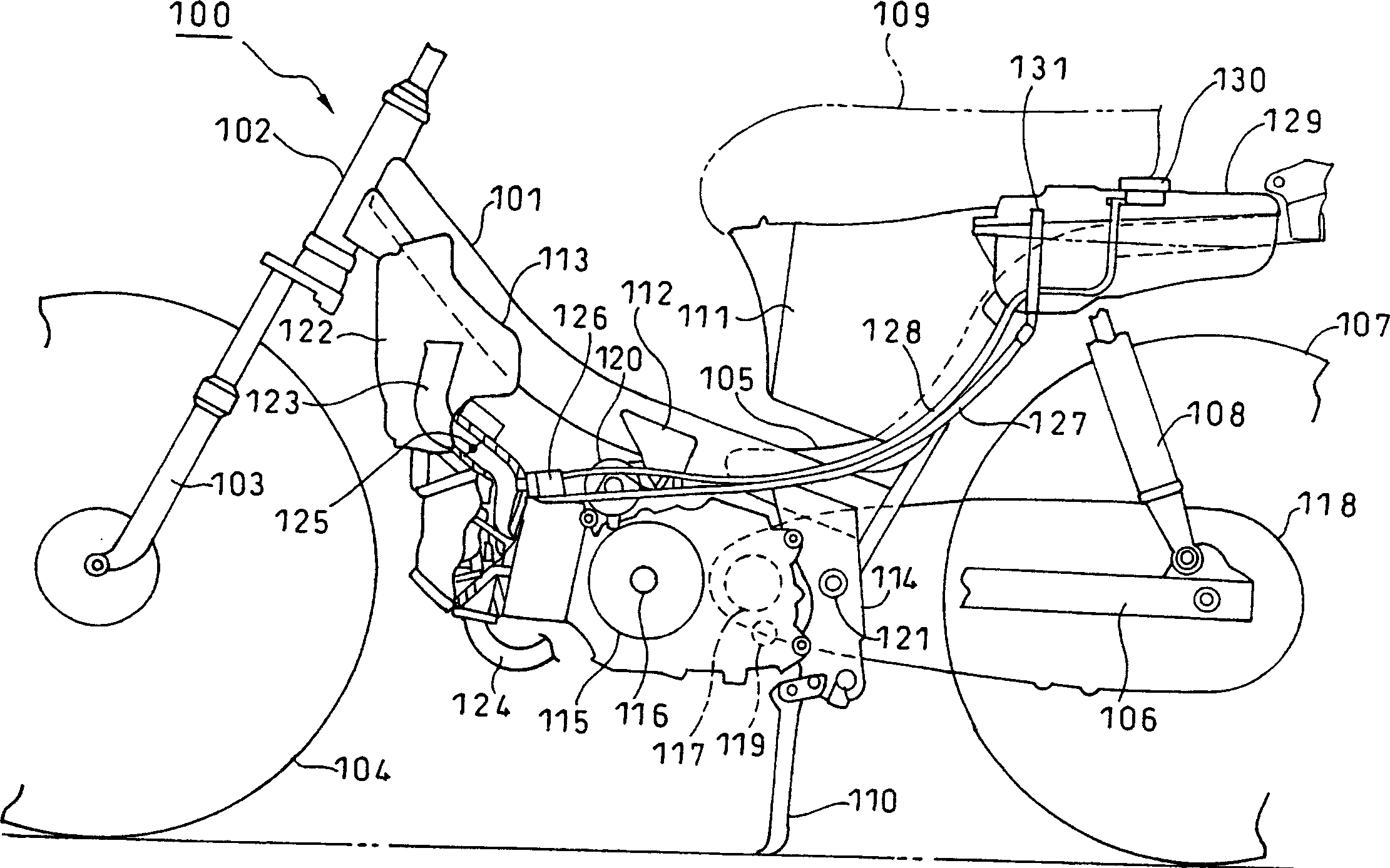

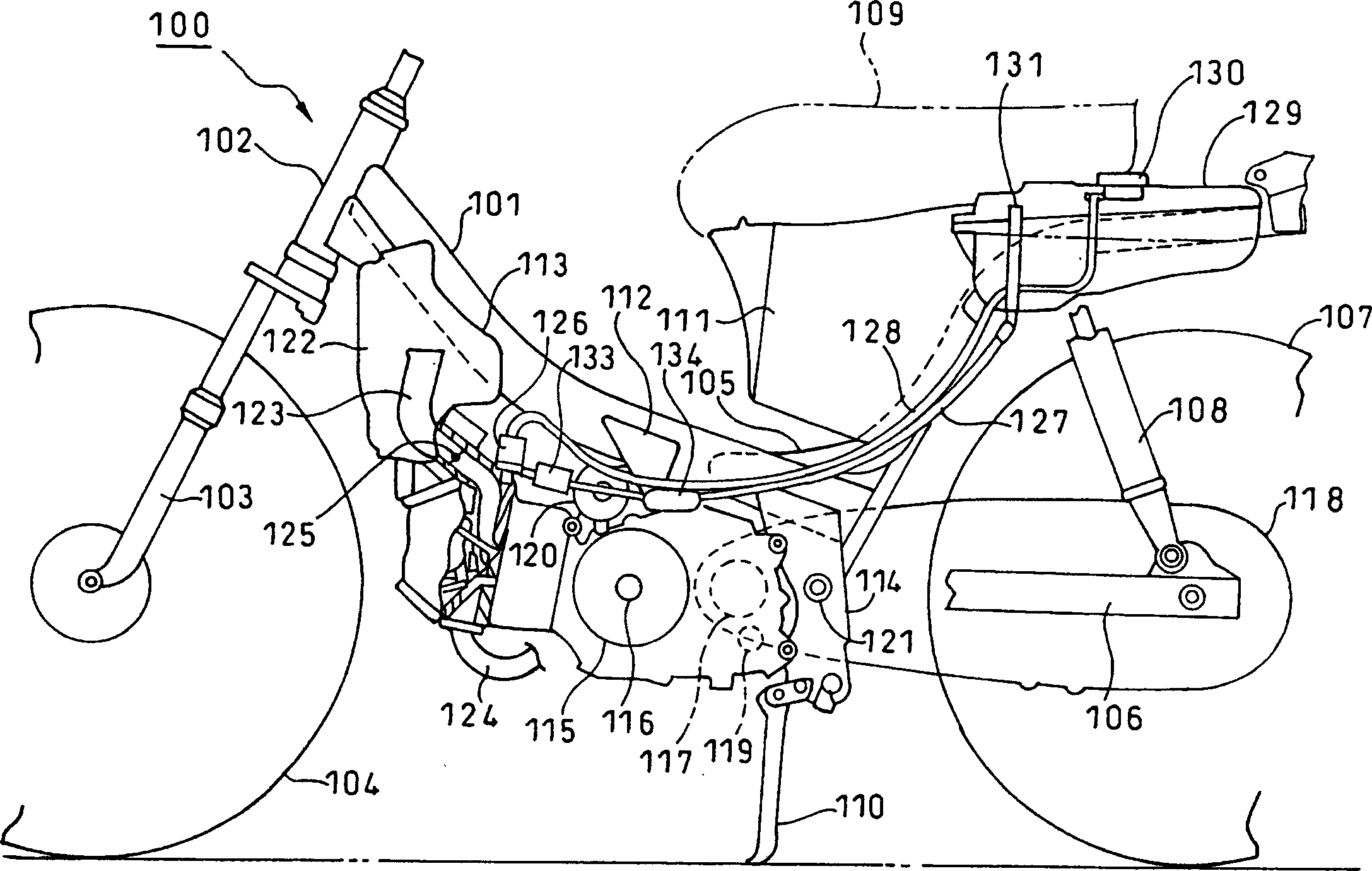

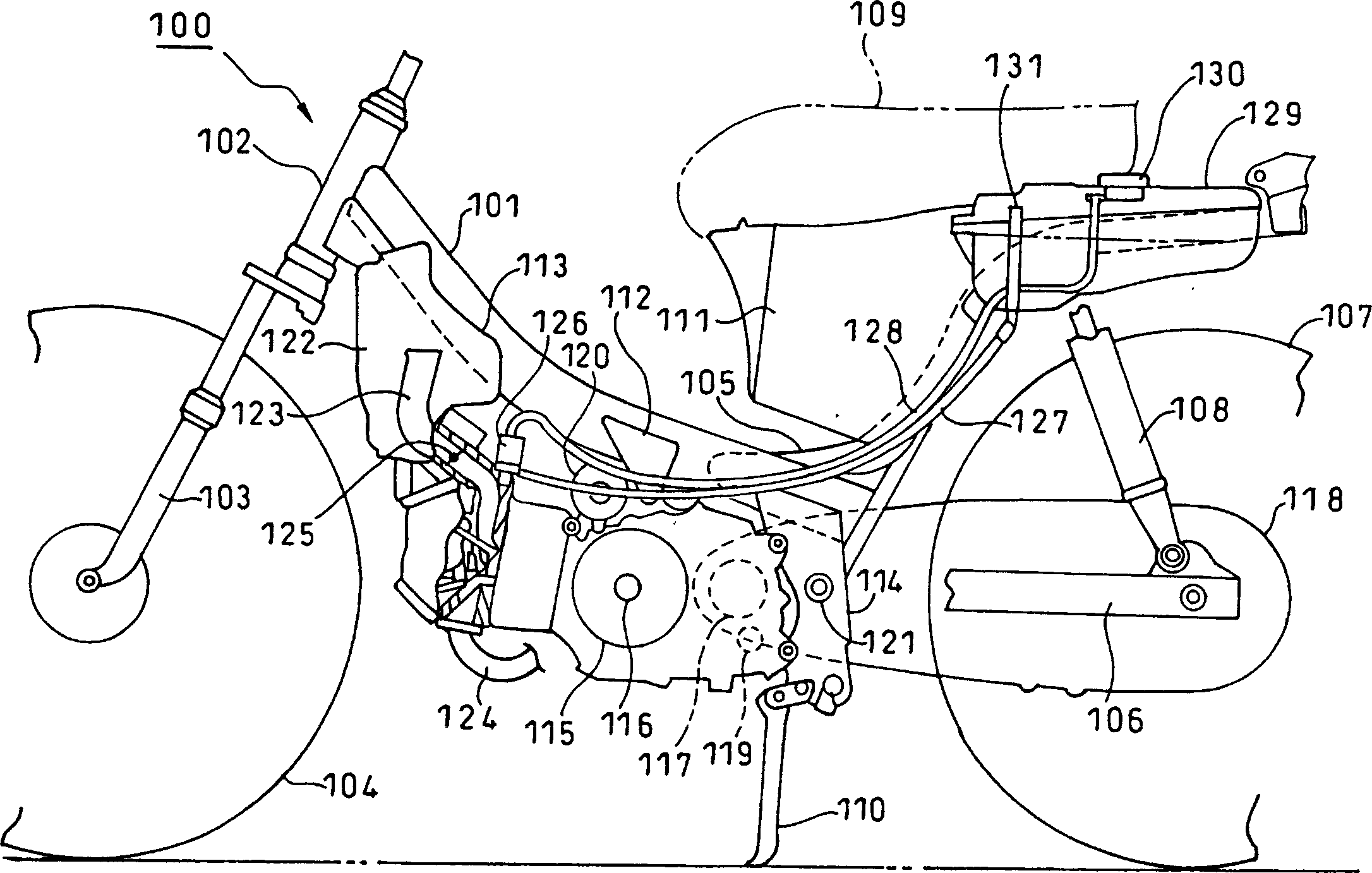

[0026] Hereinafter, embodiments of the present invention will be described in detail with reference to the drawings. The present invention is based on the premise of using a pump-injector integrated with a fuel pump and an injection nozzle for downsizing a fuel injection type fuel device, thereby achieving downsizing, eliminating the problem of arrangement space, and improving the degree of freedom of arrangement.

[0027] Figure 8 It is a schematic diagram showing an example of a pump / injector used in the present invention, and is an example in which a fuel pump including, for example, a solenoid type plunger pump is disposed in the sub tank 10 . Fuel is supplied from the fuel tank to the sub tank 10 . pump drive unit 11 such as Figure 9 As shown in a simplified example, by energizing the solenoid coil 16, the plunger 18 with the spring 17 moves up and down, and the fuel is sucked from the suction port 12 having a check valve to the fuel pump part 14, and the fuel is suck...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com