Manufacture of electric connector

A manufacturing method and technology of electrical connectors, applied in the direction of contact manufacturing, etc., can solve the problem that the terminal contact part 703 and the outer conductor 704 are not easy to be positioned accurately, and achieve the effect of reliable holding force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

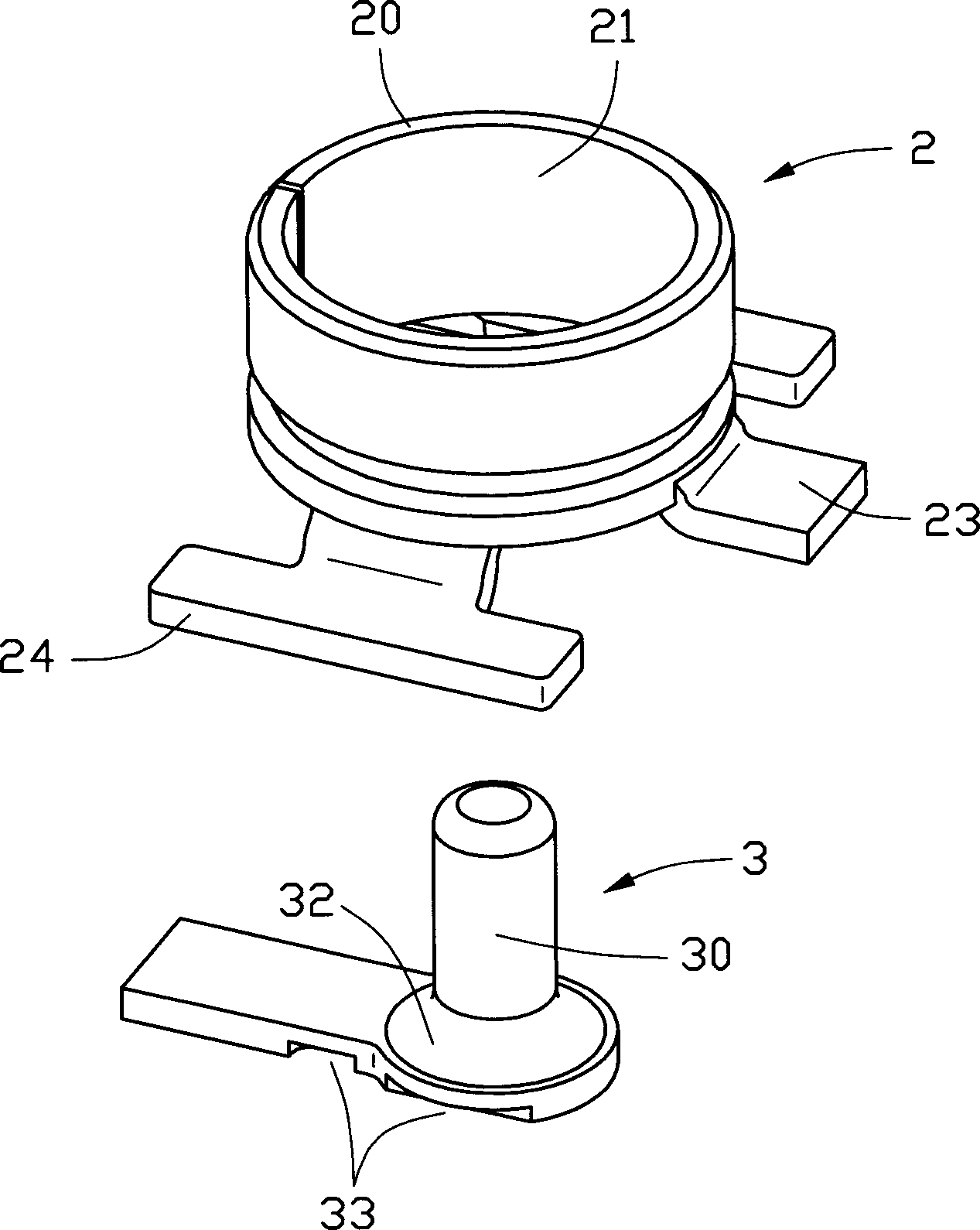

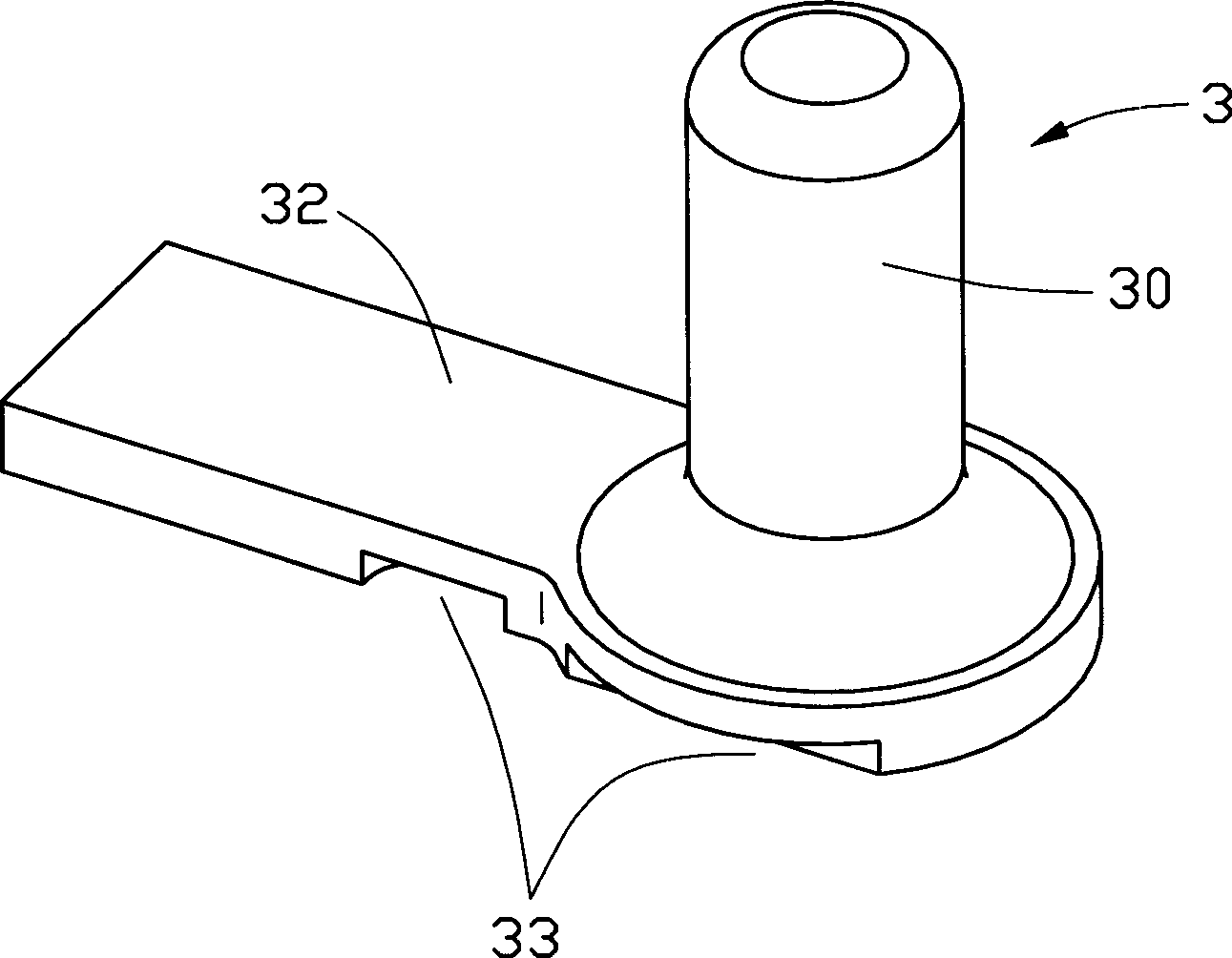

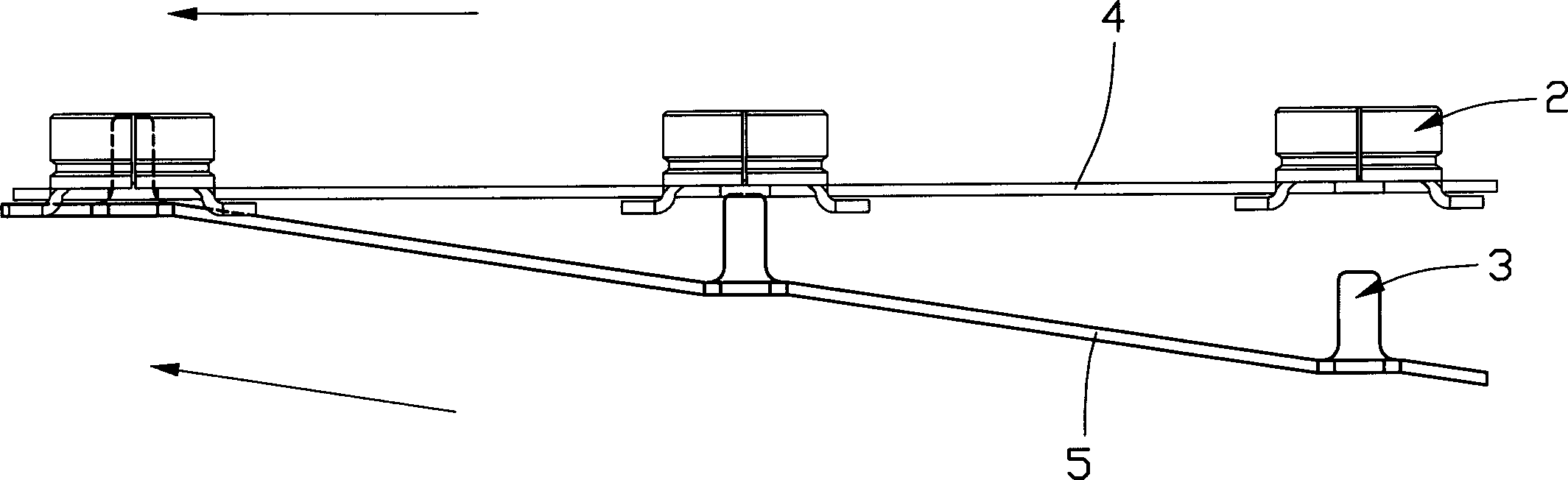

[0015] Please refer to figure 1 , figure 2 , Figure 5 and Figure 6 As shown, the electrical connector 100 manufactured by the present invention includes a metal shell 2 , a central terminal 3 and an insulating body 6 , wherein the metal shell 2 and the central terminal 3 are integrally formed in the insulating body 6 . The metal shell 2 includes a ring body 20 , a pair of welding feet 24 extending outward from the bottom side of the ring body 20 and a connecting portion 23 , and the ring body 20 is surrounded by a receiving portion 21 . The central terminal 3 includes a base portion 32 and a terminal contact portion 30 extending vertically upward along the base portion 32 and accommodated in the receiving portion 21 of the ring body 2 . In addition, several indentations 33 are provided on the base portion 32 to enhance the holding force between the insulating body 6 and the central terminal 3 .

[0016] Such as image 3 , Figure 4 and Figure 7 As shown, the manufa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com