Rotary clamp tool

A technology of fixtures and rotating parts, which is applied in the field of rotating fixtures, can solve the problems of inaccurately guiding the clamping rods, etc., and achieve the effects of reducing height, reducing rotation stroke, and increasing service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example 1

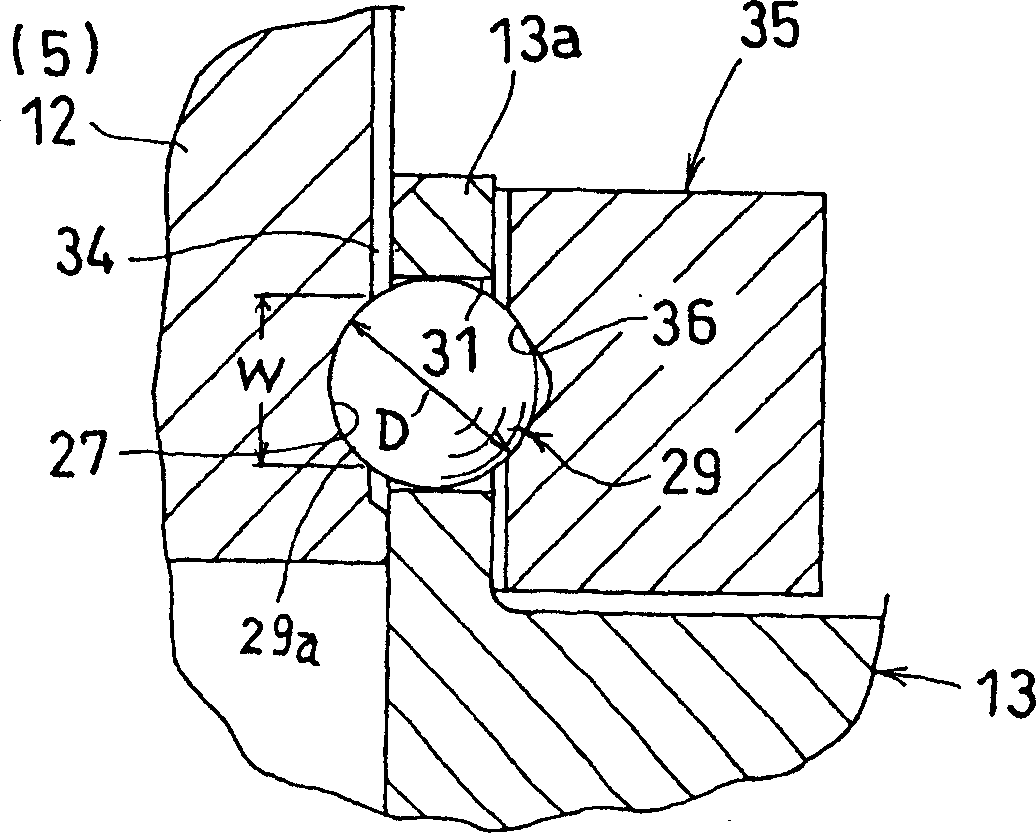

[0088] As in the first embodiment, the outer diameter of the lower sliding portion 12 is set smaller than that of the upper sliding portion 11 . In this way, the lead of the helical rotation groove is shortened, thereby reducing the rotation stroke of the clamping rod 5 .

[0089] Figure 11 A third embodiment of the present invention is shown. Figure 11 is a partial cross-sectional elevation view of the rotating fixture, which is similar to Figure 7 .

[0090] Figure 11 The third embodiment of Figure 7 The structures shown differ only in the following respects.

[0091] omitted Figure 7 Sleeve 35 is shown. The packing 32 prevents the engagement ball 29 supported by the inner wall 13 a of the support cylinder 13 from coming off.

[0092] Figure 12 Showing a first variant of the third embodiment, the figure is similar to Figure 11 .

[0093] Figure 12 The first variant of is different from Figure 11 The structure shown is in the following respects.

[009...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com