Optic fibre grating packing device

A fiber grating and packaging device technology, applied in the coupling of optical waveguide, optics, light guide, etc., can solve the problems of system performance degradation, inaccuracy, and obstacles to the practical use of fiber gratings, and achieve the effect of simplified design and uniform internal stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Embodiments of the present invention are described in detail as follows in conjunction with accompanying drawings:

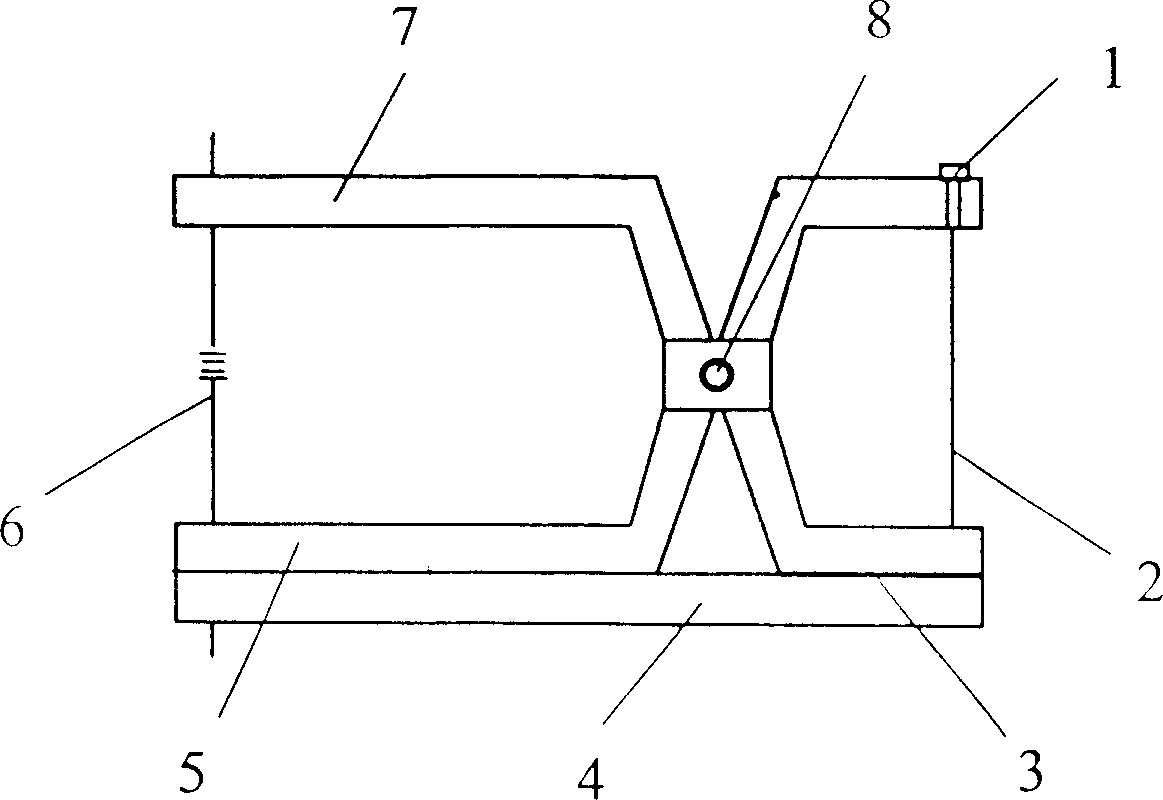

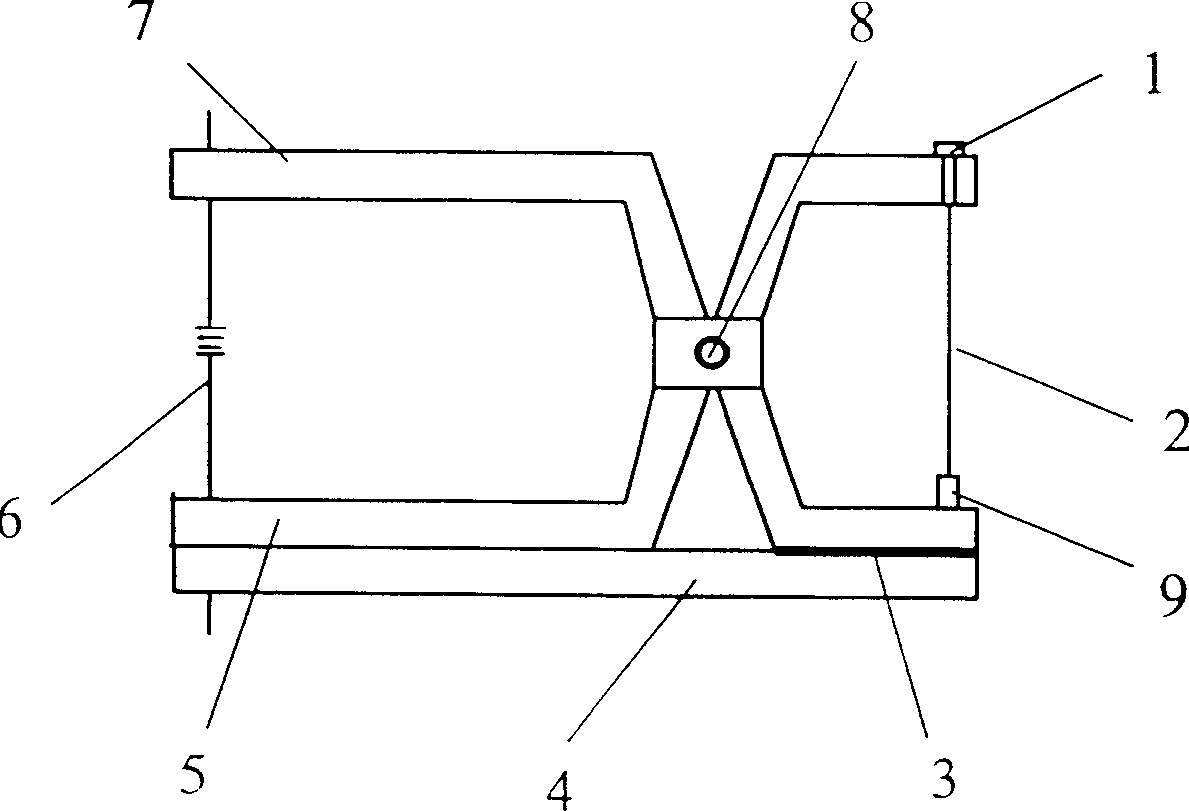

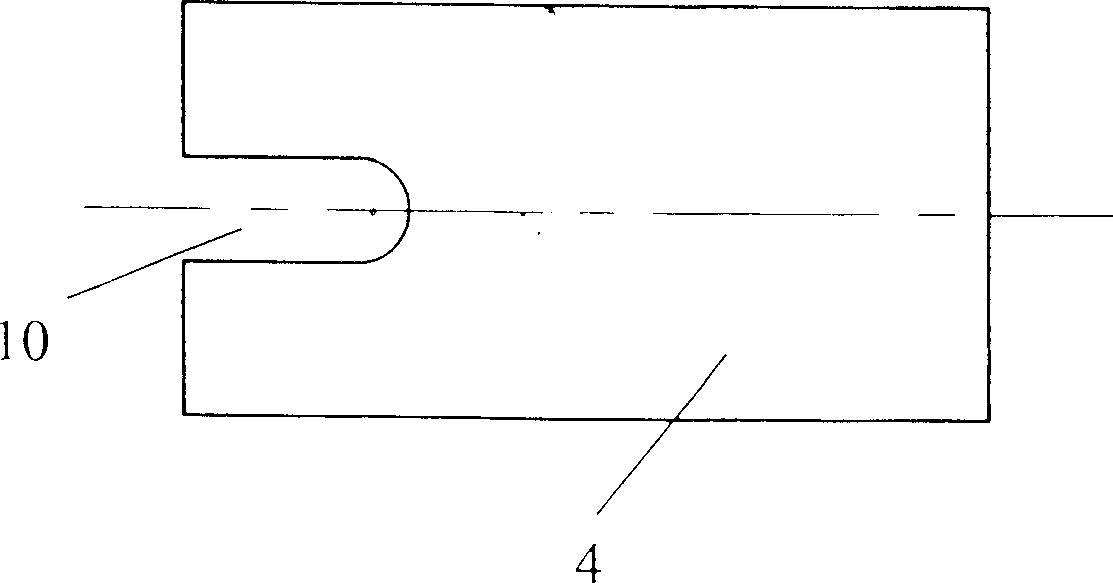

[0022] Such as figure 1 , image 3 As shown, it includes a fiber grating 6, a metal wire 2, a screw 1, a base 4 and two V-shaped brackets 5 and 7. The two V-shaped brackets 5, 7 are connected by an intermediate hinge 8 to form a scissors-shaped structure, and then the fiber grating 6 is glued between the left inner sides of the two V-shaped brackets 5, 7 by epoxy resin. Then one end of the metal wire 2 is also bonded to the lower end of the right side of a support 5 by epoxy resin, and the adjusting screw 1 is installed on the short arm of the other V-shaped support 7, and the other end of the metal wire is bonded to the screw rod 1 by epoxy resin. . The lower right end of the V-shaped bracket 5 is bonded to the base 4 through a fixed key or epoxy resin, and the lower left end is free to expand and contract. There is a gap 10 on the base 4 bonded with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com