Electric absorption modulation distribution feedback laser of mixed wave guide structure and producing method

An electro-absorption modulator and electro-absorption modulation technology, applied in semiconductor lasers, lasers, laser parts, etc., can solve the problems of low laser light output efficiency, affecting laser life, and difficult to reach laser thresholds.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

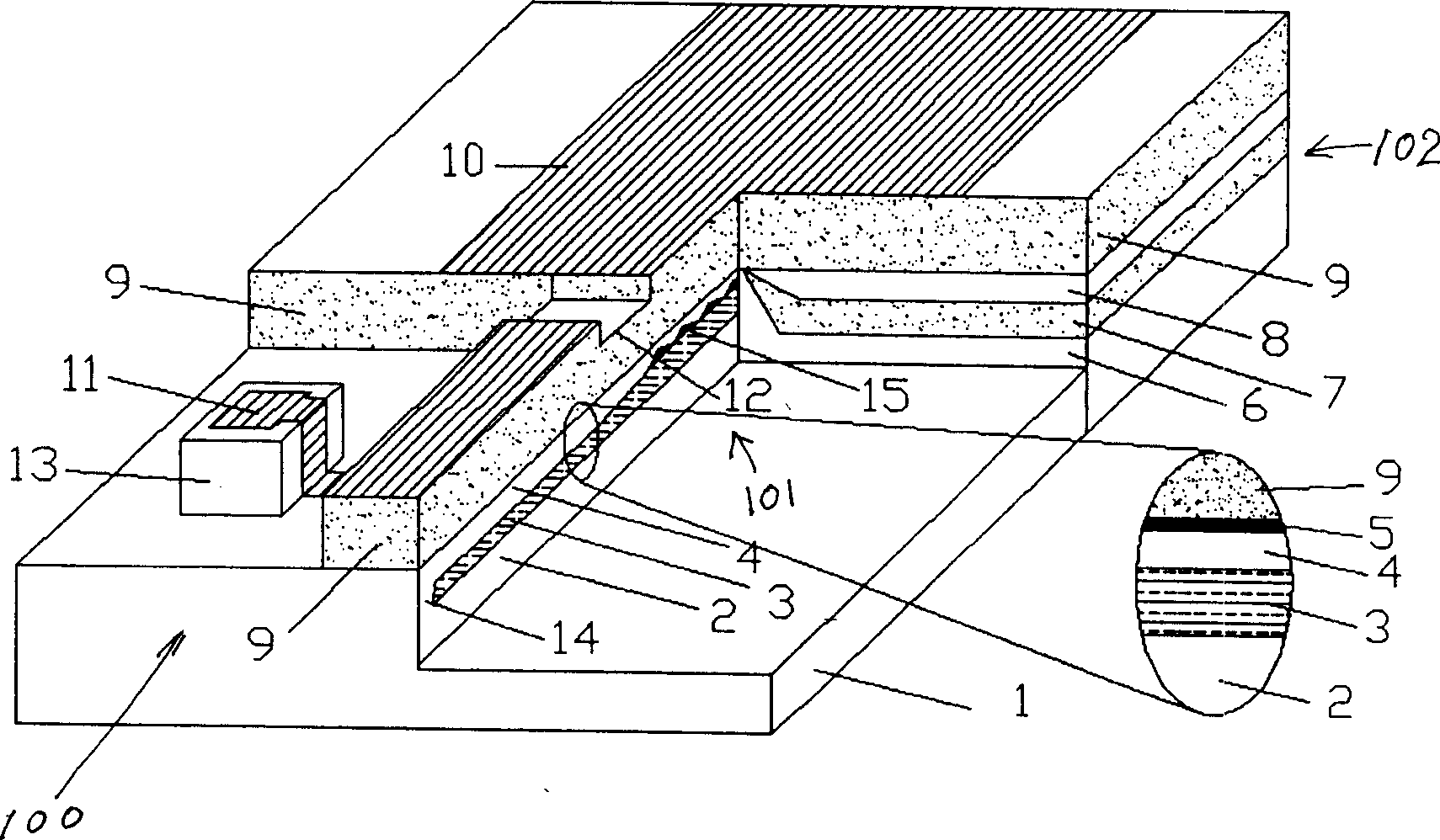

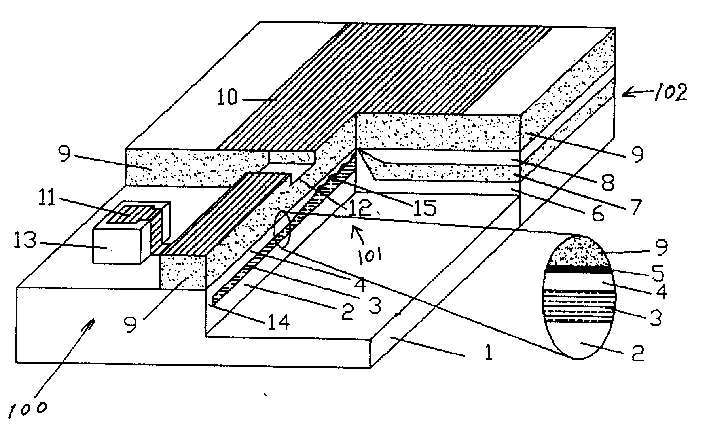

[0026] The invention combines the advantages of the buried strip structure and the ridge waveguide structure, adopts the buried strip structure in the laser part, and adopts the ridge waveguide structure in the modulator part, and makes full use of the advantages of these two structures in the laser and modulator; After the laser part is buried with a heterojunction, the threshold can be reduced and the efficiency can be improved, and there is no problem of interdiffusion of iron and zinc buried in semi-insulating InP, and the service life can be guaranteed; after the modulator part uses a ridge waveguide structure, the parasitic capacitance can be reduced , The high-speed operation of the modulator can be guaranteed; a ridge waveguide structure is used between the laser and the modulator, which is easy to achieve a high degree of isolation between the laser and the modulator, and reduces crosstalk.

[0027] An example of the present invention is as follows. like figure 1 As ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap