Electroacoustic converter

A technology of electroacoustic converters and converters, applied in piezoelectric/electrostrictive transducers, resonant transducers, circuits, piezoelectric devices/electrostrictive devices, etc., can solve problems such as temperature rise and local loss , to achieve the effect of reducing the internal loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

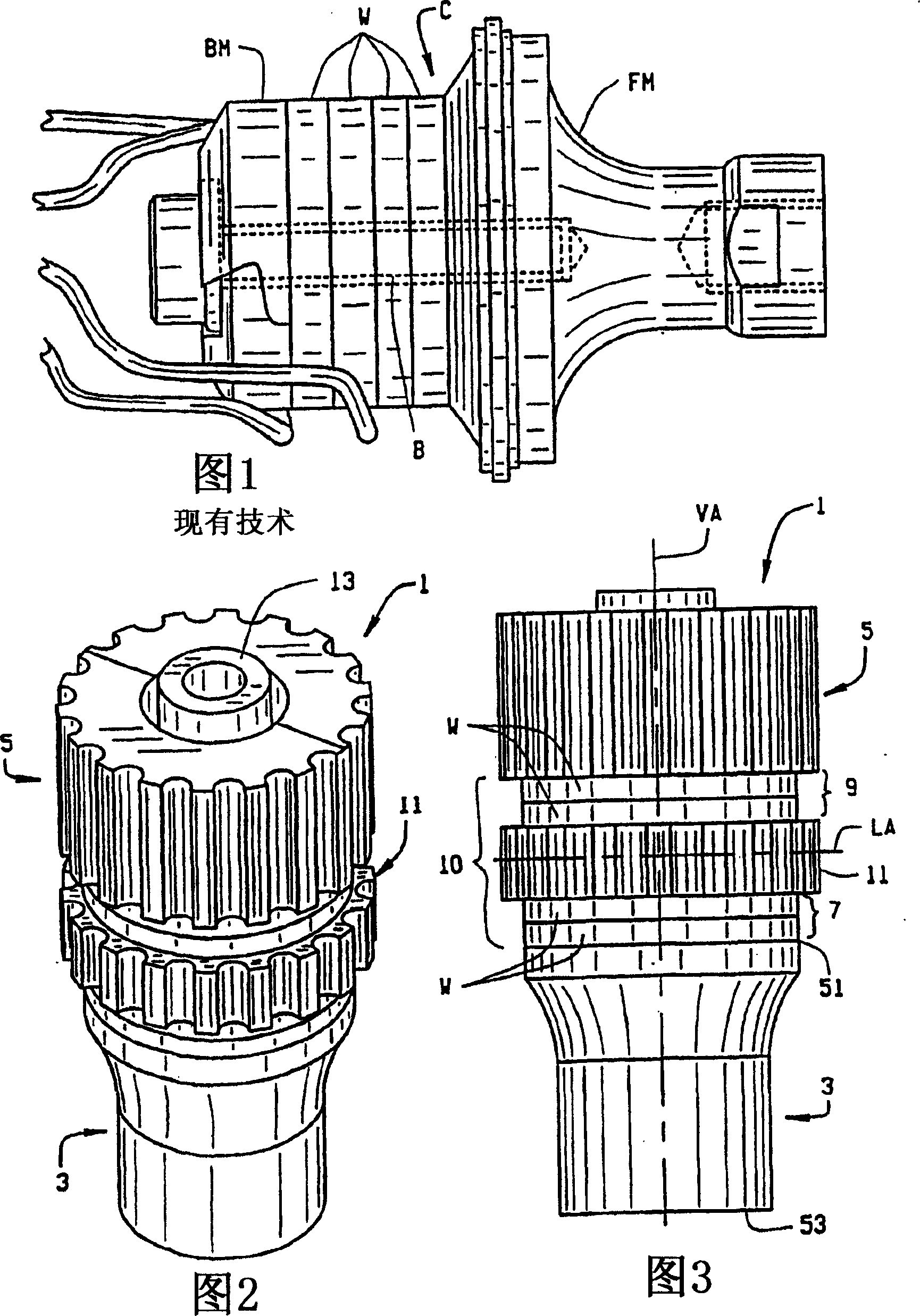

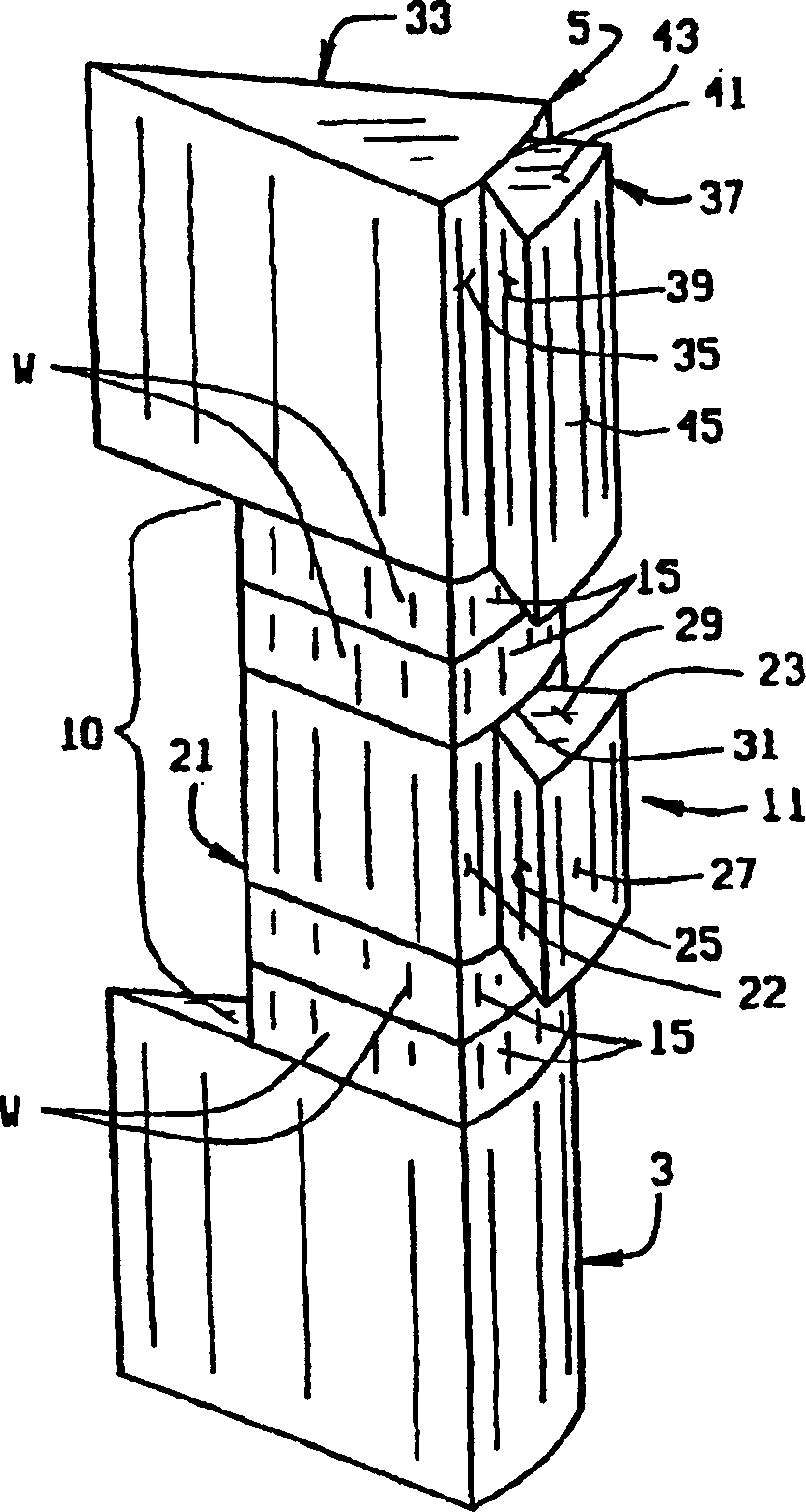

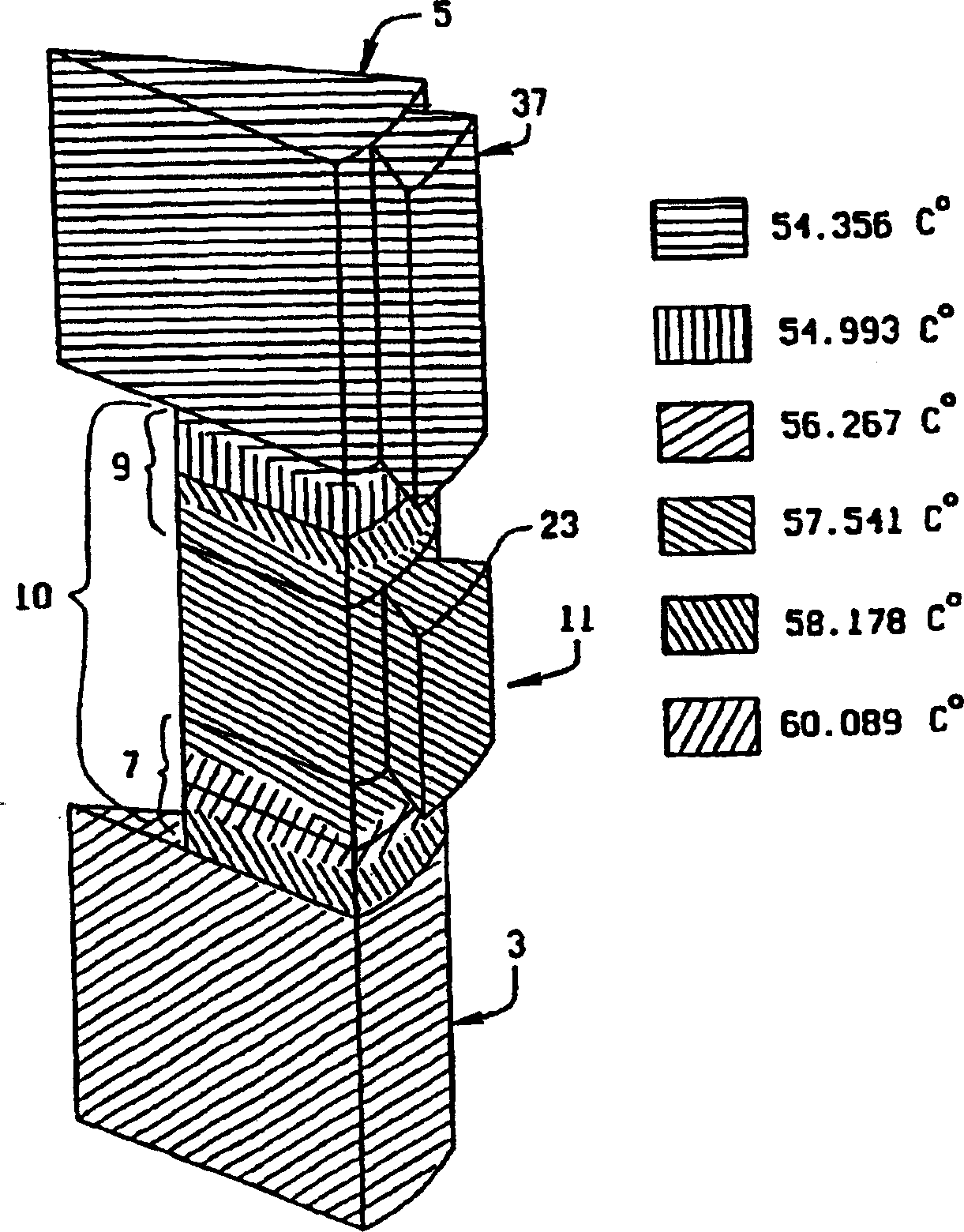

[0039] The electroacoustic transducer 1 of the present invention is generally shown in FIGS. 2 and 3 . The converter 1 converts electrical energy into mechanical vibration of a predetermined frequency. It is circular in cross-section and includes a longitudinal or vertical axis VA.

[0040] The converter 1 comprises a metal front driver body 3, a metal rear driver body 5, a front ceramic stack 7, a rear ceramic stack 9 and a spacer 11 arranged between the front and rear ceramic stacks. Fixture 13 (similar to bolt B in Fig. 1) passes axially through rear drive body 5, ceramic stacks 7 and 9 and extends to front drive body 3 to clamp spacers between front and rear ceramic stacks 3 and 5 11. As shown in Figure 2, the ceramic stacks 7 and 9 are substantially symmetrical about the shim 11, and the ceramic stack / shim assembly is substantially symmetrical about the transverse axis LA. Each ceramic stack has two ceramic sheets W. The number of sheets in the front and rear ceramic st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com