Stainless steel union for composite plastic-steel pipes and its connection method

A technology of stainless steel pipes and composite pipes, which is applied in the direction of pipes/pipe joints/fittings, pipe connection layout, mechanical equipment, etc. Large and other problems, to achieve the effect of reducing space occupation, high pressure bearing strength, and large passing flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

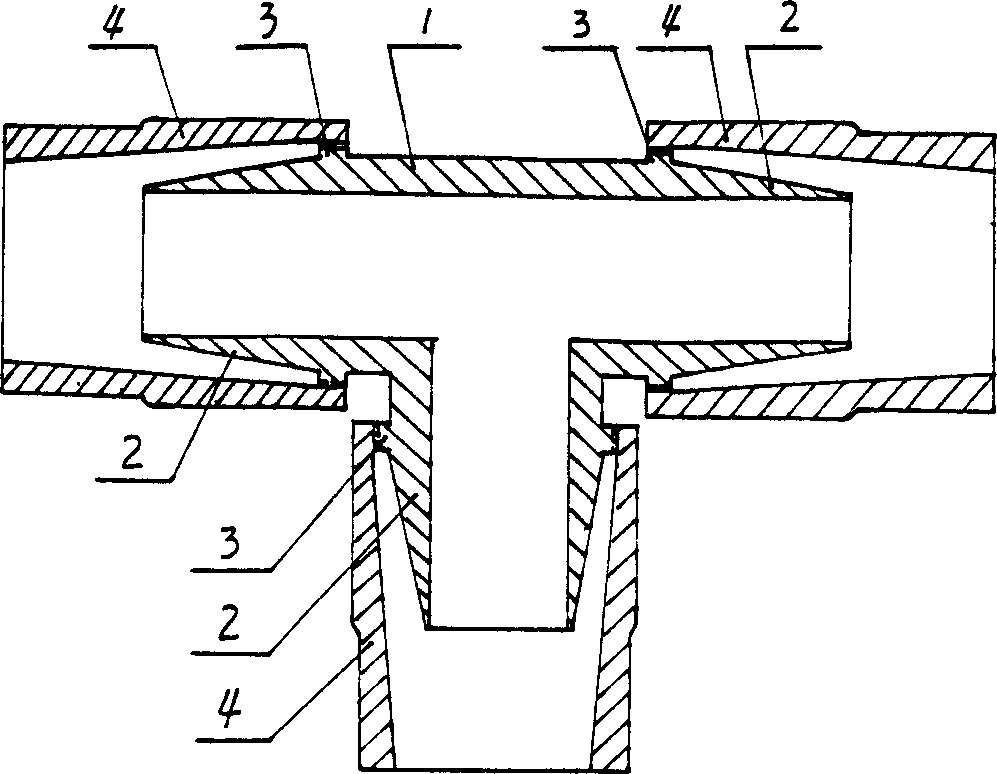

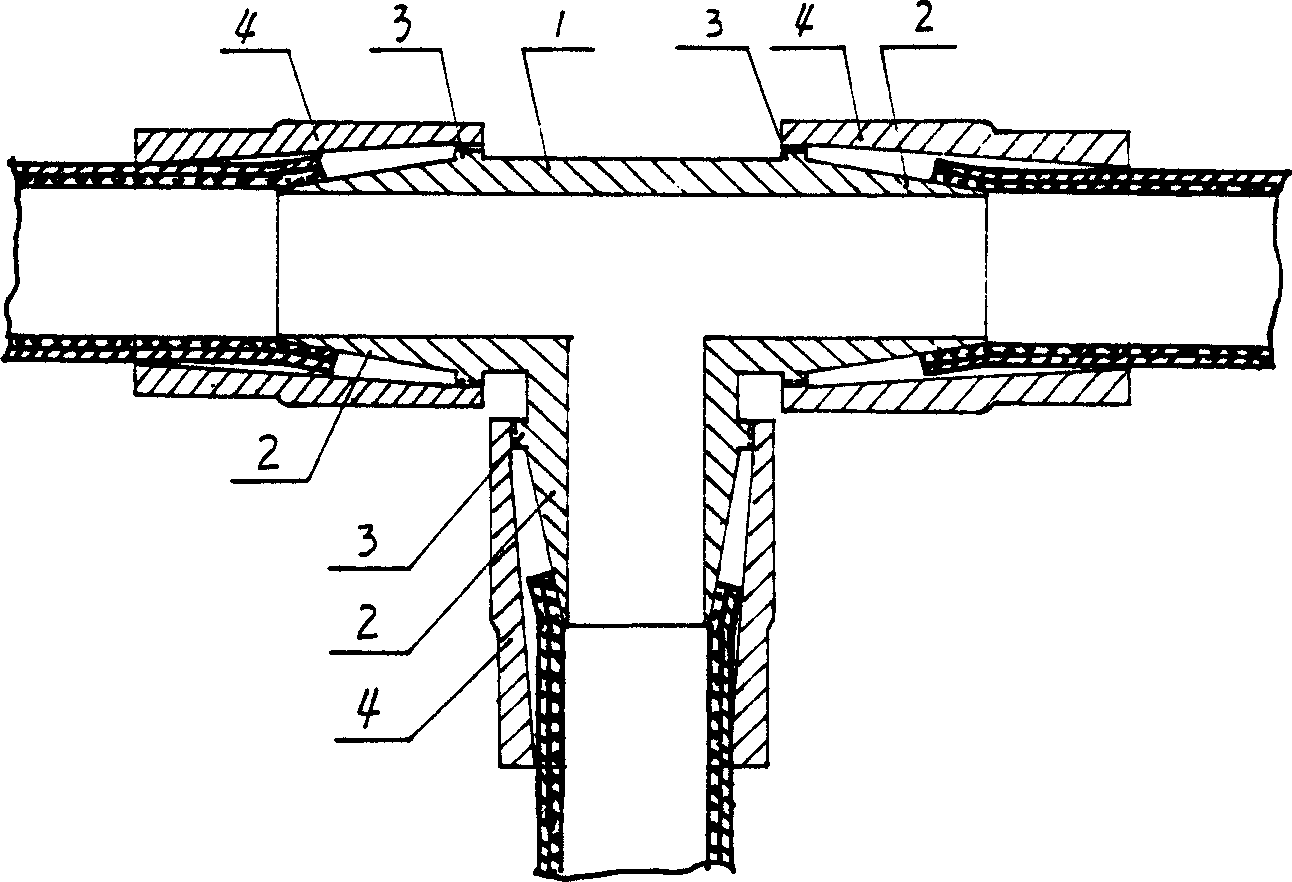

[0014] Example 1: Refer to the attached figure 1 . Stainless steel pipe connector for plastic-steel composite pipes. The pipe connector 1 is made of stainless steel. The plastic-steel composite pipe connector 2 in the pipe connector 1 is in the shape of a hollow truncated cone and is located at the rear of the plastic-steel composite pipe connector 2. A threaded buckle 3 is made on it, and a stainless steel tube reducing nut 4 is screwed on the threaded buckle. The stainless steel pipeline connector is a three-way or a four-way or an elbow or an oblique-through pipeline connector and is cast by a precision casting process. For the sealing connection method, refer to the attached figure 2 . As mentioned above, after the inner cavity of the stainless steel card tube reducing nut is clamped with the flaring of the plastic-steel composite pipe, the internal connection thread in the stainless steel card tube reducing nut and the thread fastener on the connecting body of the stainless...

Embodiment 2

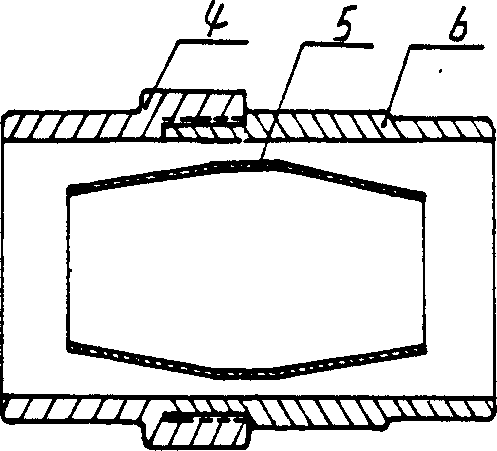

[0015] Example 2: Refer to the attached image 3 . Stainless steel pipe connectors for plastic-steel composite pipes. The left and right parts of the plastic-steel composite pipe connector 5 are hollow truncated cones, the middle part is annular and located on the stainless steel card pipe reducing nut 4 and the stainless steel card pipe reducing connector In 6, the stainless steel card tube reducing connector is provided with a thread on the outside, and the stainless steel card tube reducing nut is screwed to the card tube reducing connector. The plastic-steel composite pipe connecting body 5 and the stainless steel card tube reducing connecting body 6 are cast and processed into one body by a precision casting process. The airtight connection method "refer to the attached Figure 4 . As mentioned above, the ends of the left and right parts of the plastic-steel composite pipe connector located in the stainless steel pipe reducing nut and the stainless steel pipe reducing connecto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com