Connecting fitting for peripherally ribbed longitudinal bodies with locking retaining projecting element

A technology of elongated bodies and accessories, applied in the direction of pipes/pipe joints/fittings, passing components, mechanical equipment, etc., which can solve problems such as expensive tools and needs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

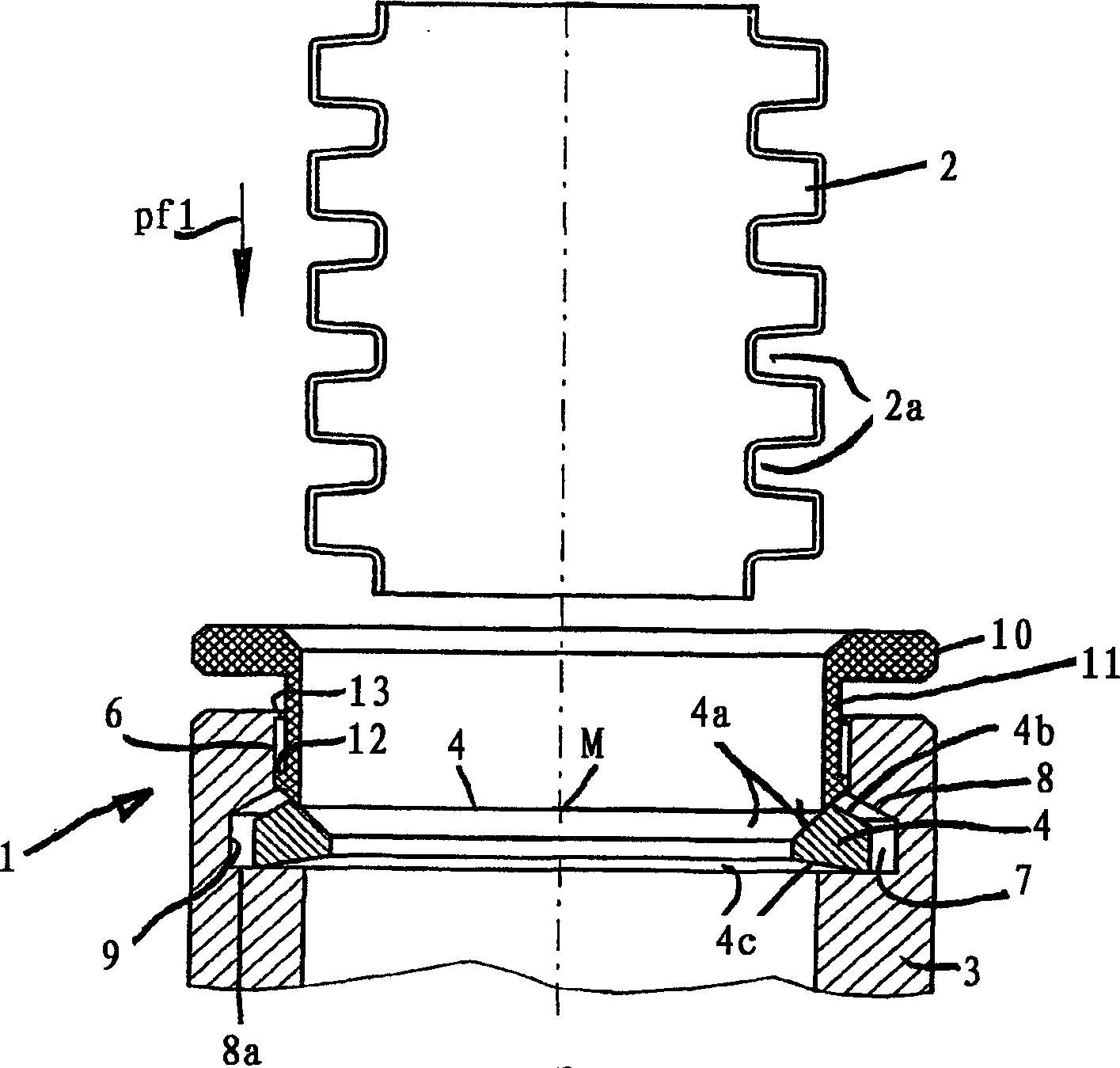

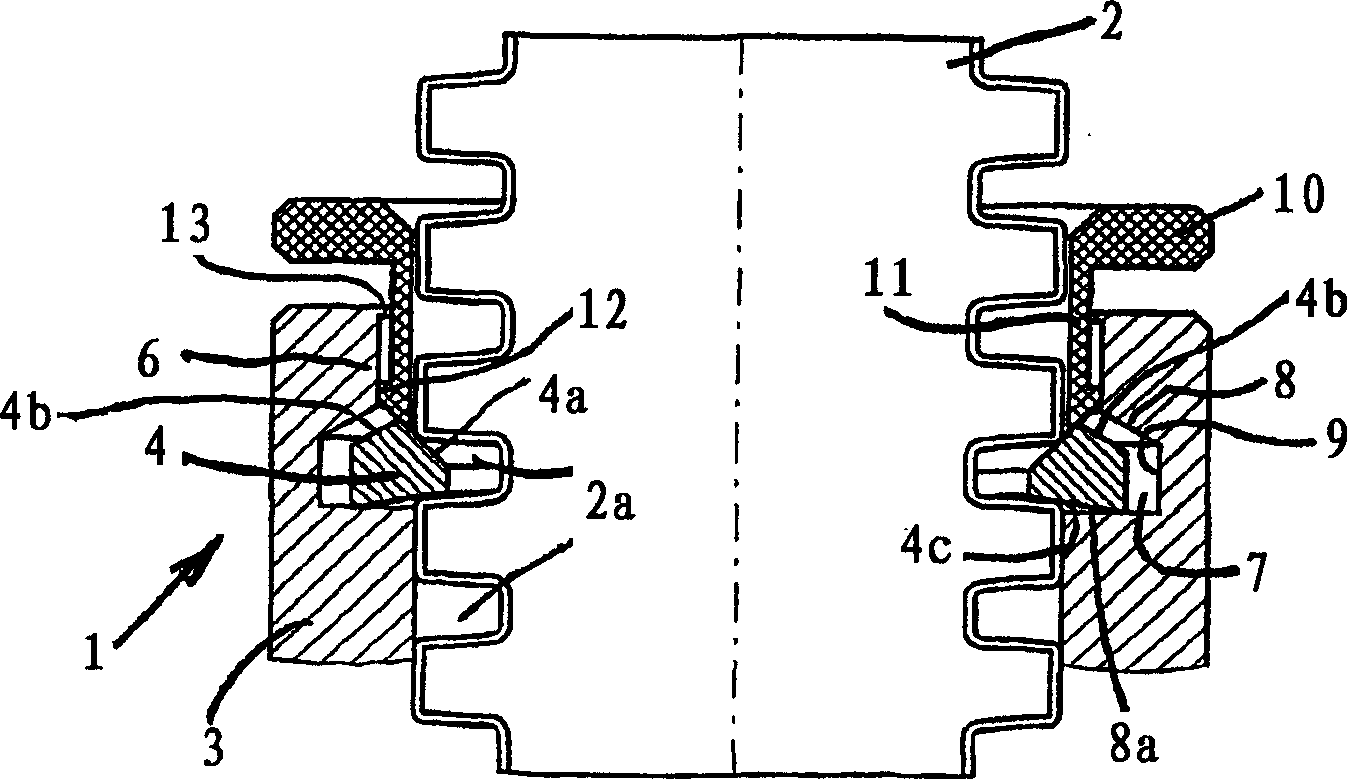

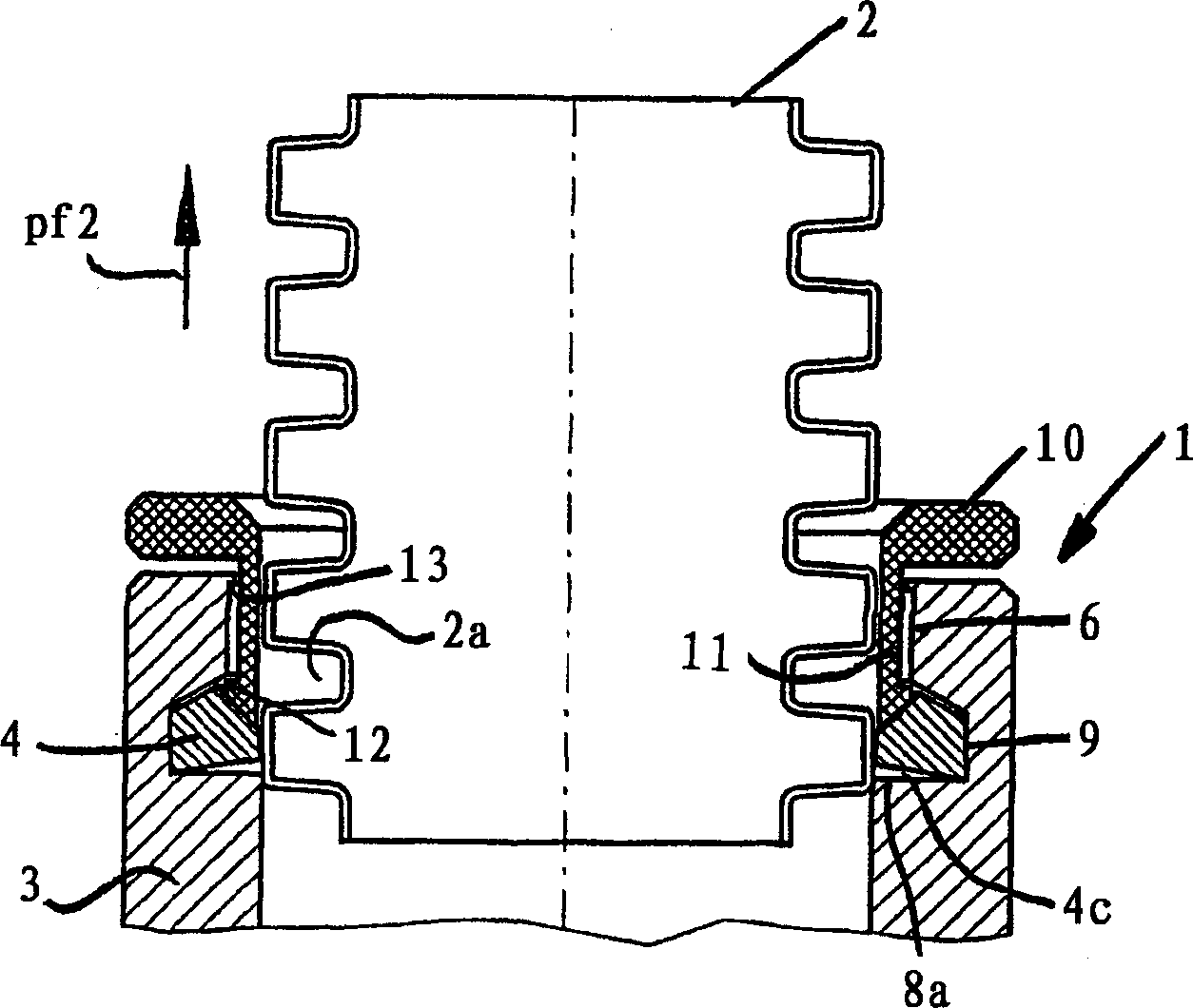

[0024] Connecting accessories marked with 1 throughout are used to fix or fasten or join circumferentially ribbed elongated bodies, i.e. objects having alternating annular protrusions and recesses on their outer surface, as shown for example in the examples Out of the corrugated hose 2.

[0025] The connection attachment 1 has a clamping sleeve 3 into which the elongated body, ie the corrugated hose 2 in the exemplary embodiment, can be inserted axially and secured by a clamping projection which will be described further on.

[0026] In this case, at least one clamping ring 4 is used as the clamping projection, which is placed or fixed axially in the clamping sleeve 3 and which, in its seated position, is elastically expandable in the radial direction to such an extent , so that its internal cross-section or internal diameter, that is, its internal clear width corresponds to the maximum external cross-section of the elongated body or the corrugated hose 2, so that the corrugat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com