Plastic package base, air cavity type package and their manufacturing methods

A technology of plastic packaging and packaging substrates, which is applied in the direction of electrical components, electric solid devices, circuits, etc., can solve the problems of weak adhesion strength, increase in the number of molds, and air cavity plastic packaging can not meet the needs of more miniaturized packaging, so as to achieve simplification Craft, the effect of reducing the likelihood

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

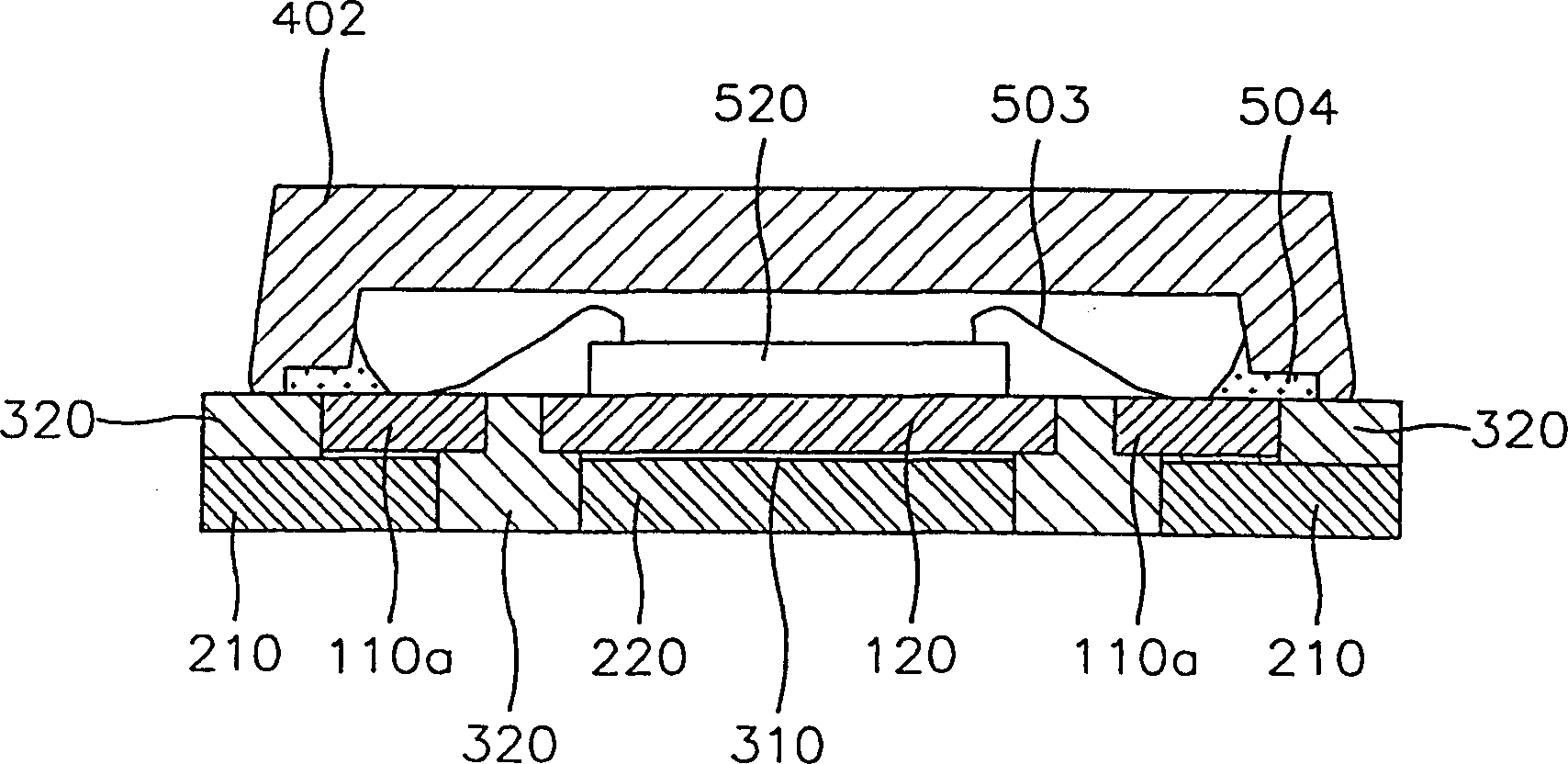

[0057] image 3 A cross-sectional view of an air cavity type plastic package according to a first embodiment of the present invention is shown. refer to image 3 , the first lead frame including the first leads 110a and the first pads 120 as internal terminals and the second lead frame including the second leads 210 and the second pads 220 as external terminals are bonded together with conductive solder. The chip 520 is bonded to the first pad 120 on the first lead frame with an adhesive (not shown), and is wire bonded to the first lead 110 a of the first lead frame with a bonding wire 503 .

[0058] The first and second lead frames are molded into a combined body with epoxy molding compound (EMC) plastic body 320 . Top surfaces of the first lead 110 a and the first pad 120 and bottom surfaces of the second lead 210 and the second pad 220 are exposed. The top surface of the plastic body 320 is flush with the top surfaces of the first lead 110 a and the first pad 120 .

[0...

no. 2 example

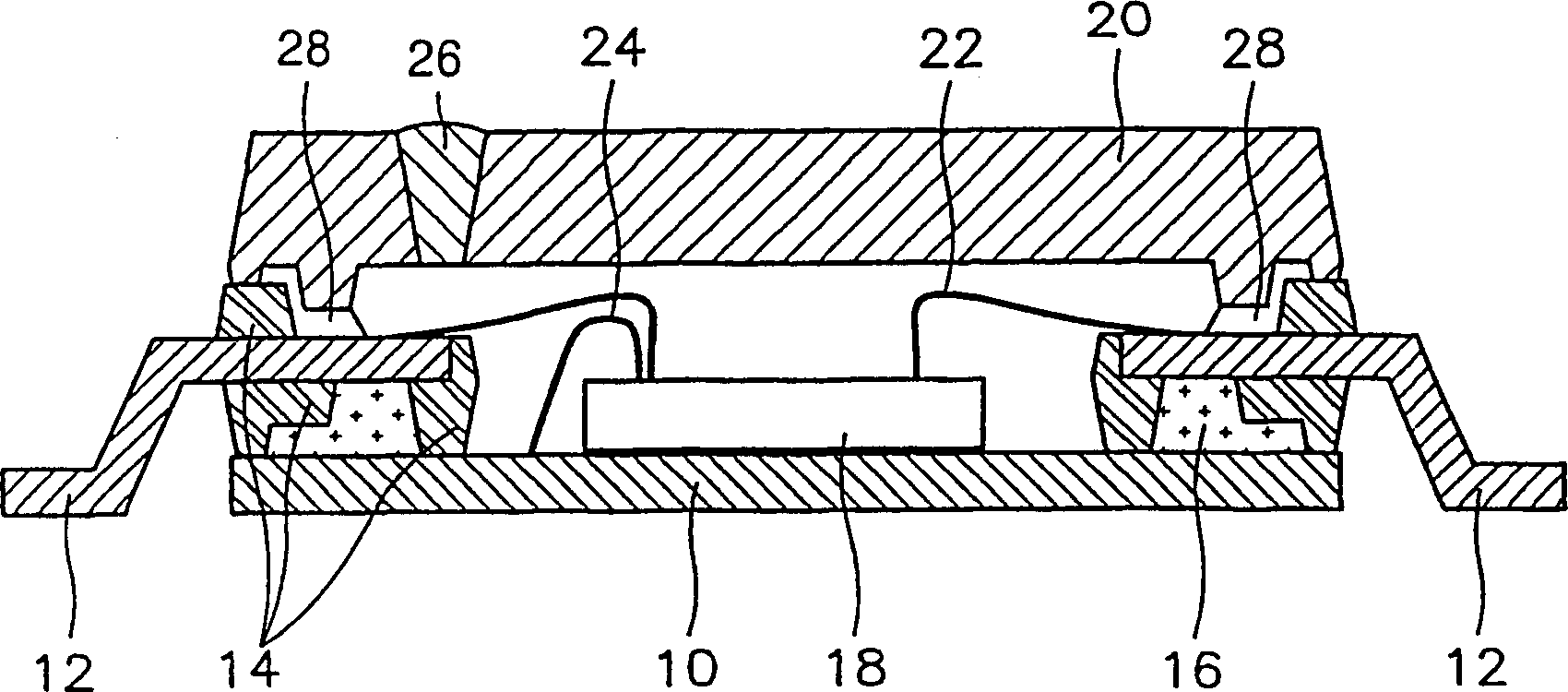

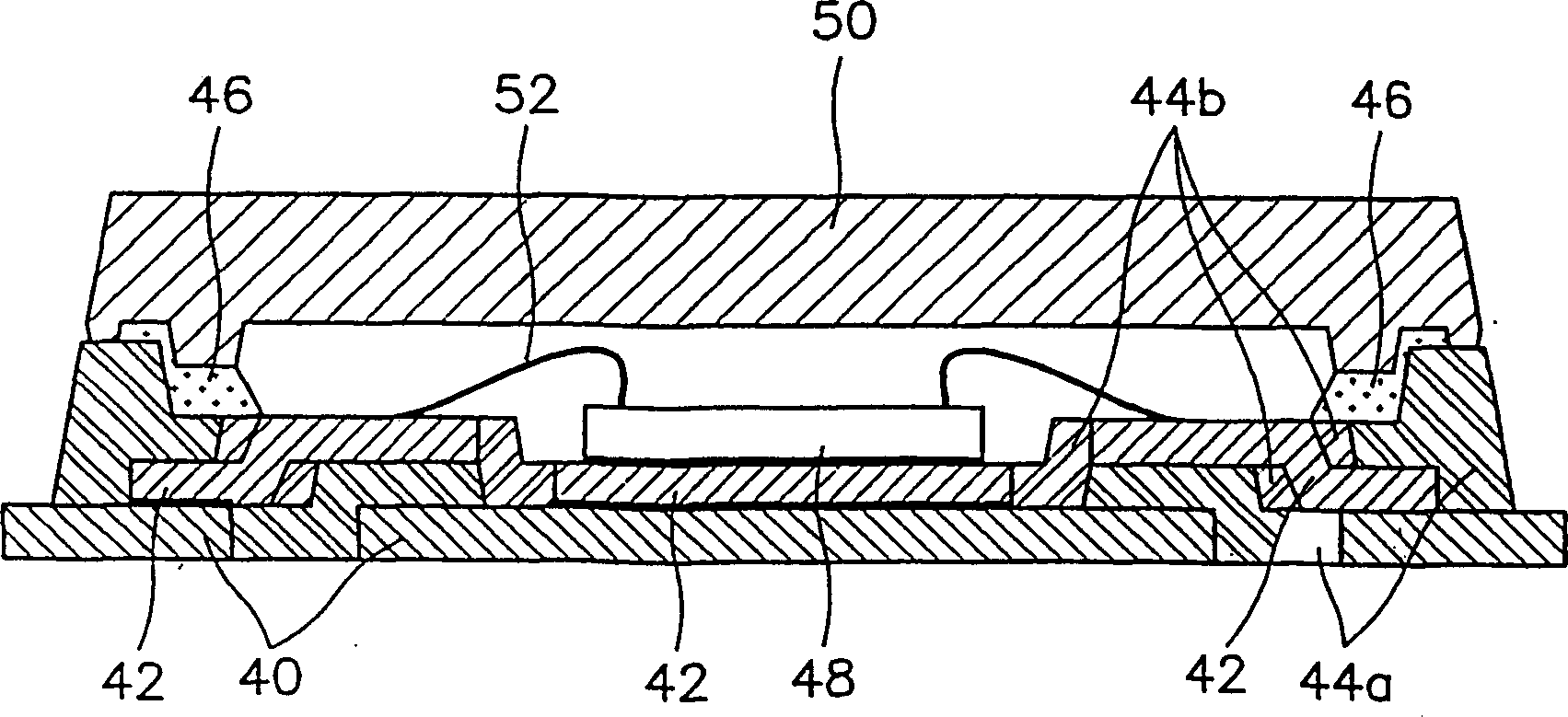

[0092] Figures 5 to 7 A sectional view showing a modification of the air cavity type plastic package according to the second embodiment of the present invention. The present invention is not limited to Figures 5 to 7 The illustrated air-cavity plastic package including various package substrates can be applied to other air-cavity plastic packages (not shown) having different package substrate structures.

[0093] refer to Figure 5 , the chip 520 is bonded to the package substrate 404 by means of an adhesive (not shown), and a bonding wire 503 is formed to electrically connect the chip 520 and the package substrate 404 . The plastic cover 410 is hermetically mounted on the package substrate with a sealant 450, thereby forming an air cavity. exist Figure 5 In , only the main components of the package substrate 404 are shown for convenience. However, in the package substrate 404 , a plurality of leads (not shown) may be formed to be electrically connected to external ter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com