Connections for vacuum systems

A technology for connection devices and vacuum equipment, applied in parts of pumping devices for elastic fluids, expansion compensation devices for pipelines, adjustable connections, etc., can solve expensive problems, achieve airtight sealing, and be easy to manufacture And adjustment, cost saving significant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

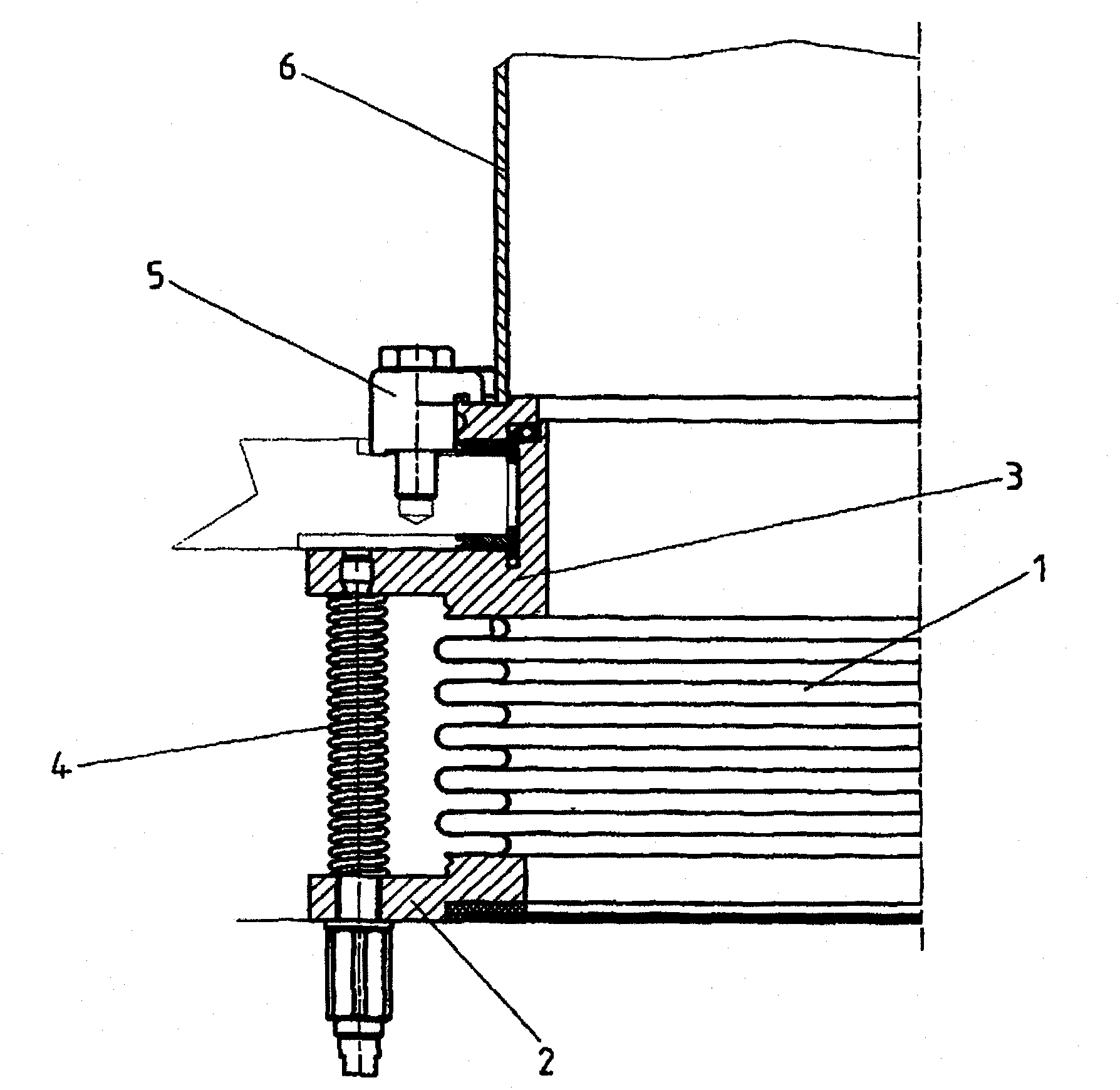

[0008] according to figure 1 Known connecting devices of this type have a bellows 1 made of metal, such as corrosion-resistant spring steel, Inconel or aluminium, the end of which, surrounding the opening, is welded to the flange 2 and the other end of which is welded. One end is welded to the ring 3 , and the outer ring 3 is connected to the flange 2 through a threaded connection 4 . Furthermore, the ring part 3 is releasably but gas-tightly connected to the pipe part 6 via a screw connection 5 . The bellows 1 allows the movement of the ring 3 relative to the flange 1 both longitudinally and transversely thereto in a limited manner. The additional mechanical connection via the threaded connection 4 with at least one screw which is surrounded by a compression spring and is relatively tensioned by it is designed in such a way that it does not impair these possibilities.

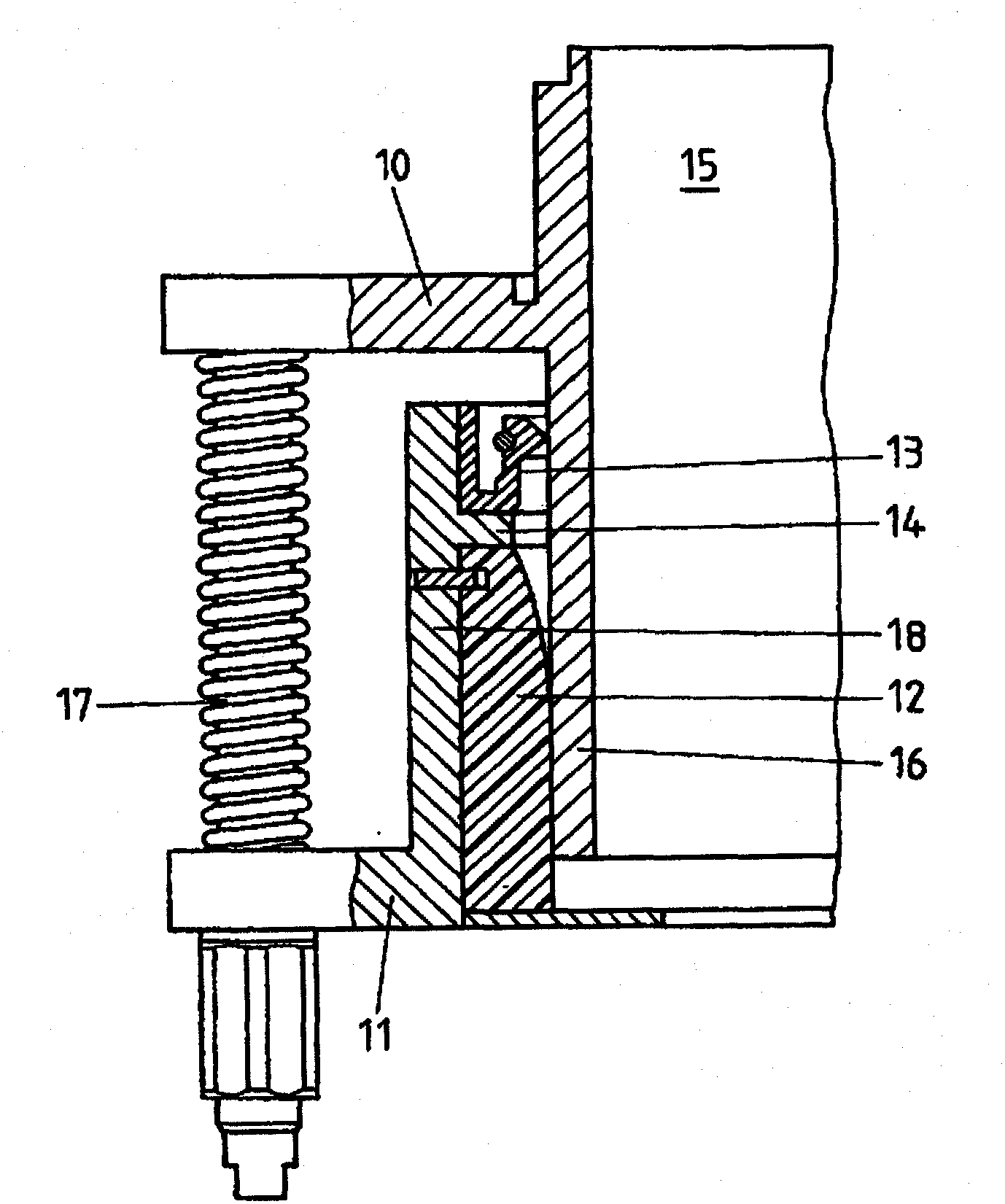

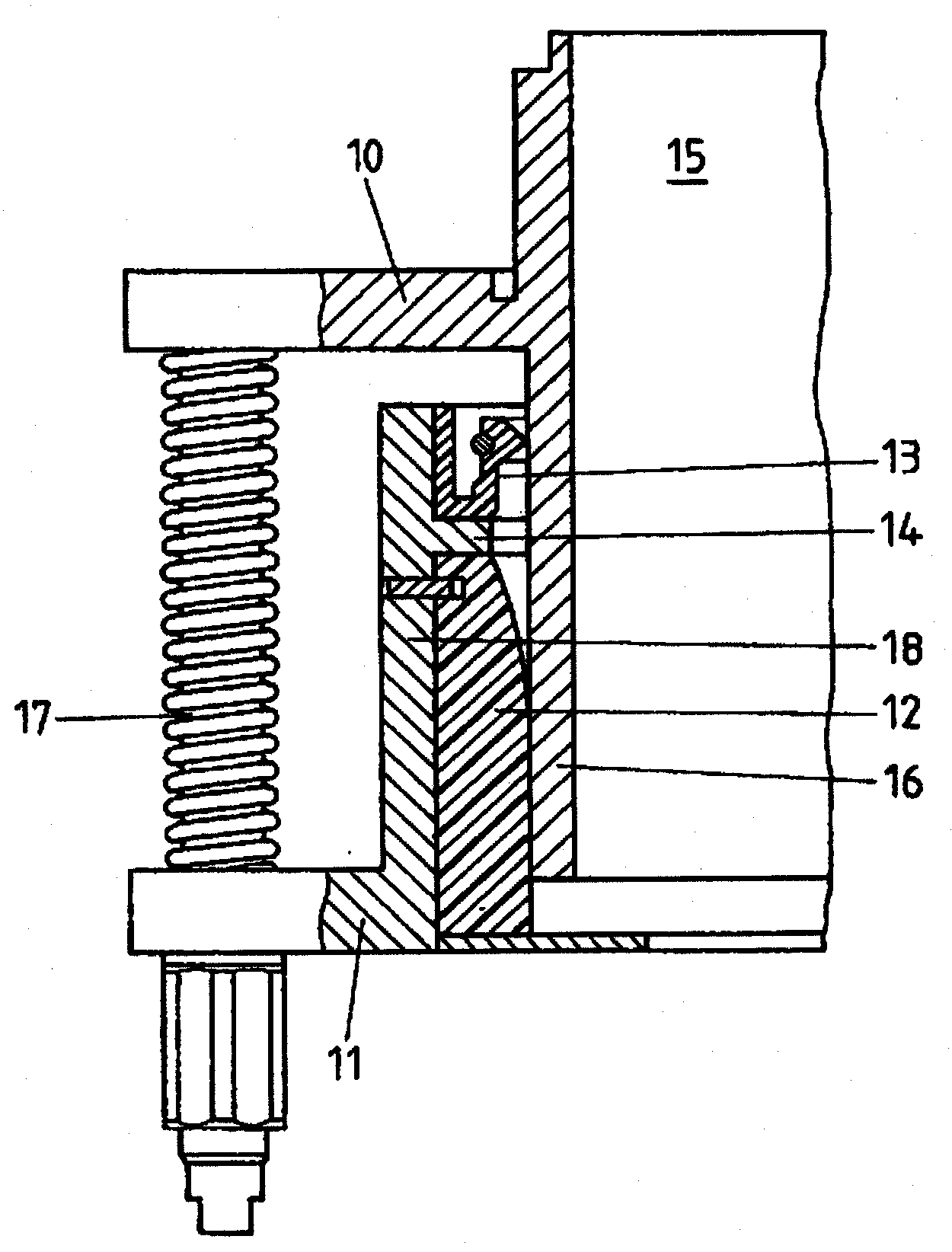

[0009] according to figure 2 The connecting device 15 according to the invention comprises two flanges ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com