Data carrier comprising gravure printed image and method for transposing image motifs into linear structures and onto gravure printing plate

A technology of data carrier and gravure printing, which is applied to the data carrier with line gravure printing images, converts the basic patterns of patterns into line structures and transfers to line gravure printing plates, and can solve the problems of easy copying and forged images, etc. Achieve dimensionally accurate results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

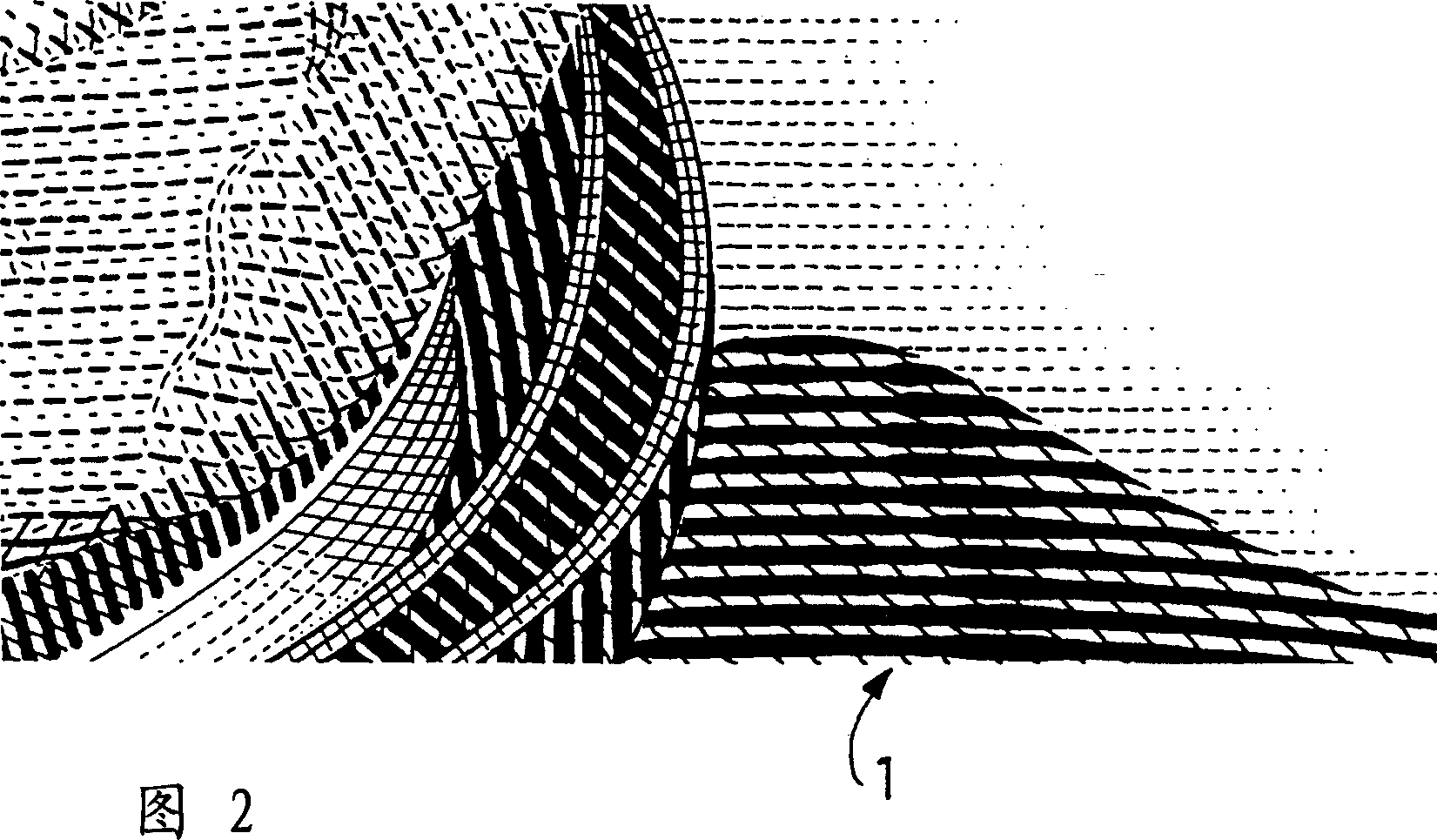

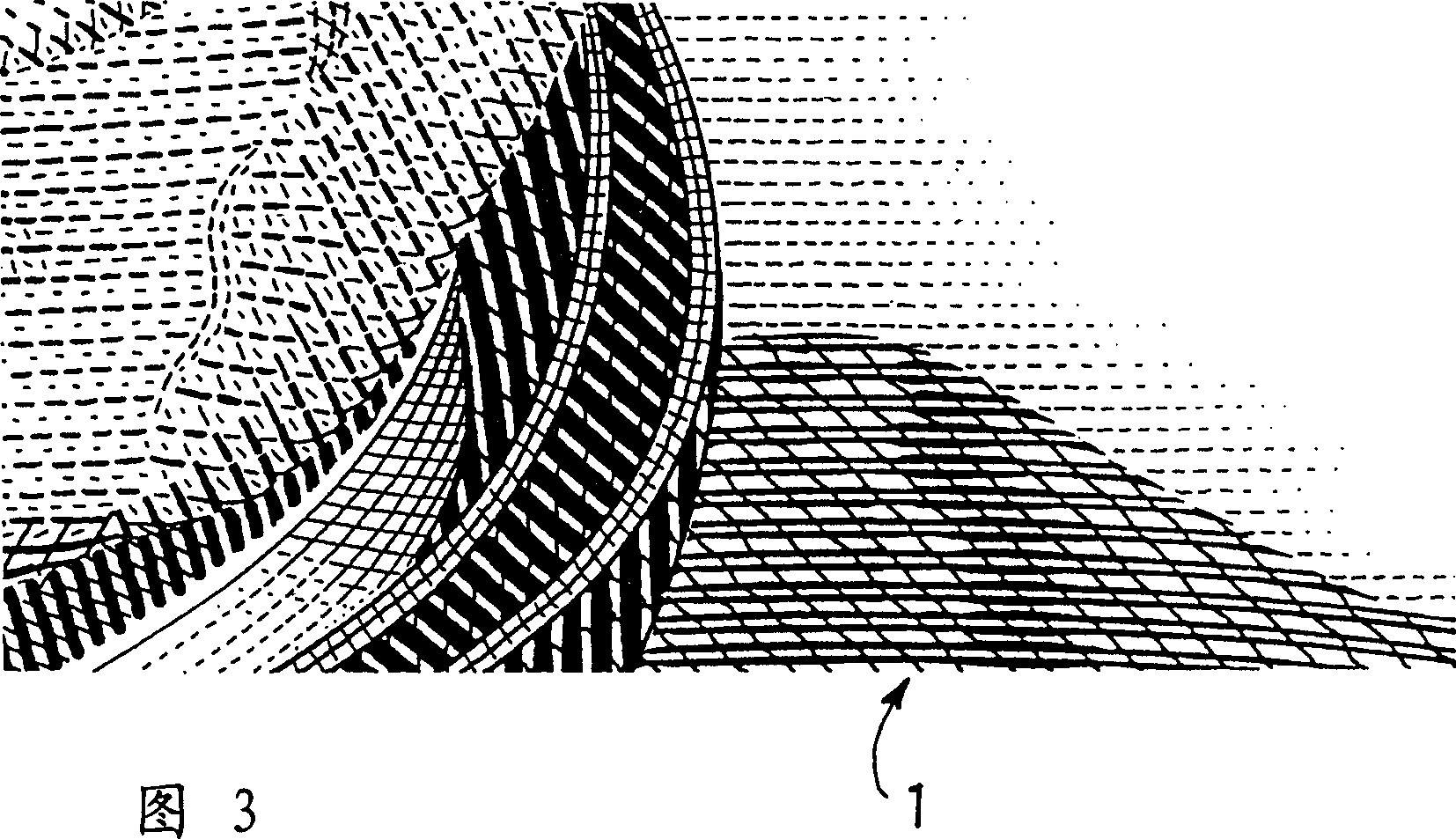

[0038] figure 1 Indicates a portrait made by engraving. That is, all outlines and picture elements are formed with varying line structures, as in usual engraved images. For ease of identification, for example in the coat and beard area of the image, these structures may consist of continuous or interrupted lines; or in the ear, cheek and forehead area by dashed or dotted lines. These images are directly engraved by hand into the metal plate or drawn by hand on paper according to methods known in the art. When converting the basic pattern of the picture into an engraving pattern, different shades and colors or grayscale values can be formed by using different forms of line structure and / or changing the line width and line distance for image areas of different tones. Thus, bright areas (such as the forehead, cheeks, and ear areas in this portrait) are best formed by fine, widely spaced lines and then dashed, dotted, or dotted. Dark image areas (such as the hat or coat in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com