On-line monitoring method for boiler expansion

A technology for boilers and boiler headers, applied in lighting and heating equipment, fluid heaters, etc., can solve the problem of insufficient scientific evaluation and analysis data of boiler safe operation status, imperfect deformation and expansion detection technology, unfavorable analysis and accident prevention, etc. problems, to achieve the effects of perfect detection technology, safe operation status evaluation and analysis data science, analysis and prevention of accidents in a timely manner

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

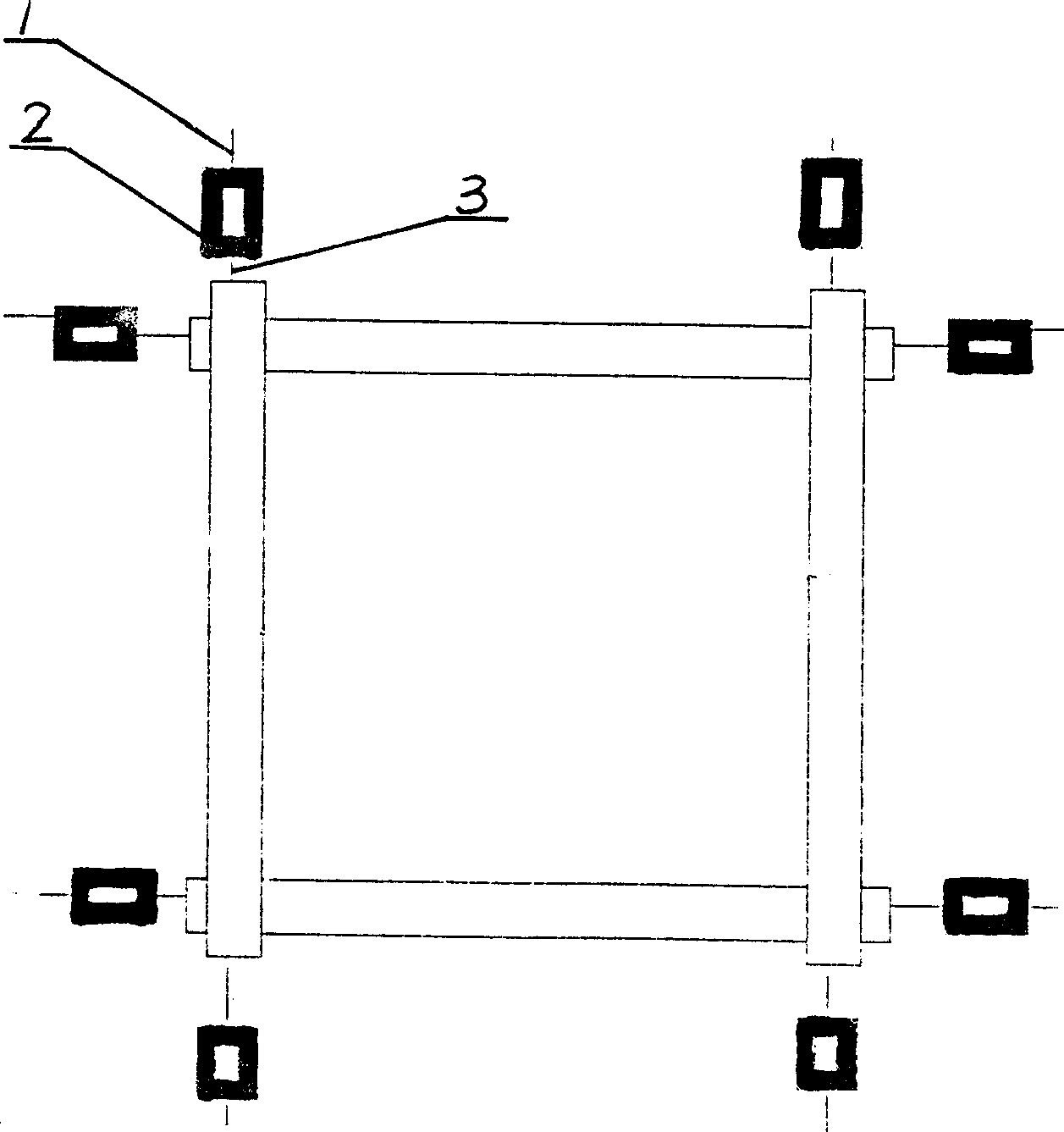

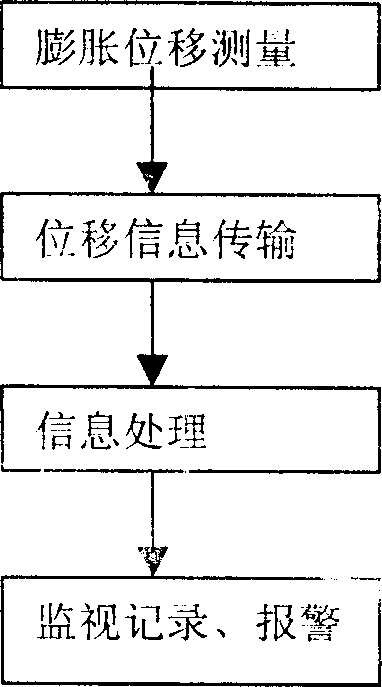

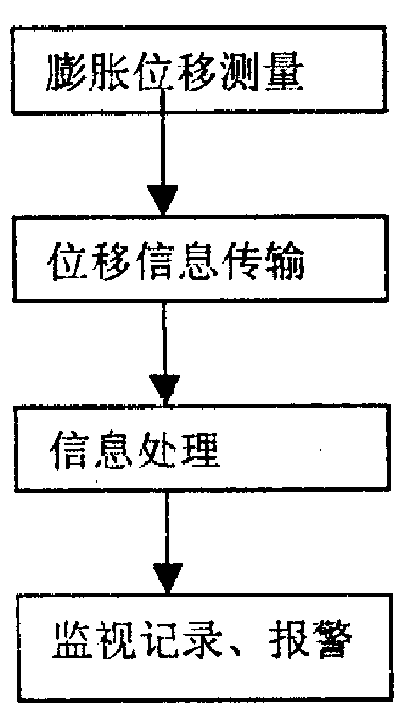

[0011] refer to figure 1 and figure 2 , install the displacement measuring element 2 on the fixed bracket corresponding to each end of the boiler header respectively, adjust the position of the displacement sensor in the cold state, make it contact with the header expansion transmission rod 3 and fix the sensor, when the boiler is ignited During operation, the temperature rises gradually, and the expansion displacement increases. When the furnace is stopped, the opposite is true. The expansion of the header to both ends is converted into digital signals by displacement sensors (including abnormal states) and transmitted to the automatic recording system and on-line monitoring. , Overrun alarm system, that is, a remote computer. The boiler expansion picture and parameters are shown on the computer screen. During the actual boiler start-up process, from the cold state to the rated working state, the expansion of the header is 85mm, which is consistent with the initial and fina...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com